Treatment method of spray washing water in activated carbon production process

A technology for the production and treatment of activated carbon, which is used in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Treatment and other problems, to achieve the effect of being beneficial to biochemical treatment, high oxidative degradation efficiency, and small impact on water quality chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

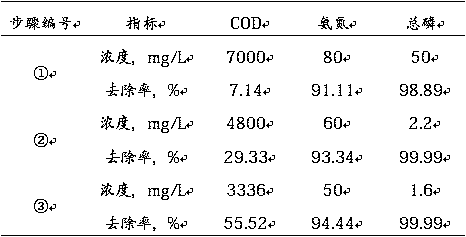

[0043] Embodiment 1 comprises the following steps:

[0044] ①Chemical precipitation: Take a certain amount of wastewater in a water bath to control the temperature at 30°C, add a fixed amount of magnesium chloride, and the dosage is based on n (Mg 2+ ):n(N):n(P)=1.5:1:1 molar ratio, slowly add liquid alkali to the wastewater during stirring at constant temperature to adjust the pH to about 9~10, and continue to stir and react for 20min under this condition, After the reaction, let it stand for 30 minutes, filter and separate, recover and purify the solid phase as a compound fertilizer for reuse, and carry out the next step in the liquid phase. After treatment, the effluent COD is 7000mg / L, ammonia nitrogen is 80mg / L, and total phosphorus is 50mg / L. The corresponding removal rates of the three are 6.7%, 91.1%, and 88.9%, respectively.

[0045] ②Magnetic flocculation and precipitation: For the tar, some macromolecular organic components and a small amount of residual total phos...

Embodiment 2

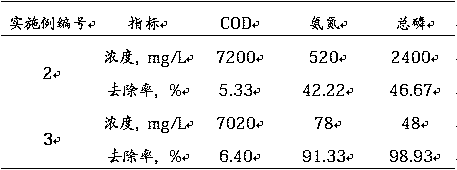

[0052] Compared with Example 1, step 1. in the dosage of magnesium chloride medicament according to n (Mg 2+ ):n(N):n(P) molar ratio is modified to 0.5:0.5:1.5, and the others are the same as in Example 1;

Embodiment 3

[0054] Compared with Example 1, step 1. in the dosage of magnesium chloride medicament according to n (Mg 2+ ):n(N):n(P) molar ratio was modified to 2:1.5:0.5, and the others were the same as in Example 1;

[0055] Example 2 and Example 3 see Table 2 for the effluent index after step 1. treatment:

[0056] Table 2 The effluent indicators of Examples 2~3 after step (1) treatment

[0057]

[0058] Insufficient addition of magnesium salt will lead to incomplete removal of ammonia nitrogen and total phosphorus in wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com