A kind of industrialized lithium iron phosphate manufacturing method and the lithium iron phosphate composite material thereof prepared

A lithium iron phosphate, iron phosphate technology, applied in the field of new energy battery materials, can solve the problems of a large amount of flushing water, poor product consistency, unstable performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

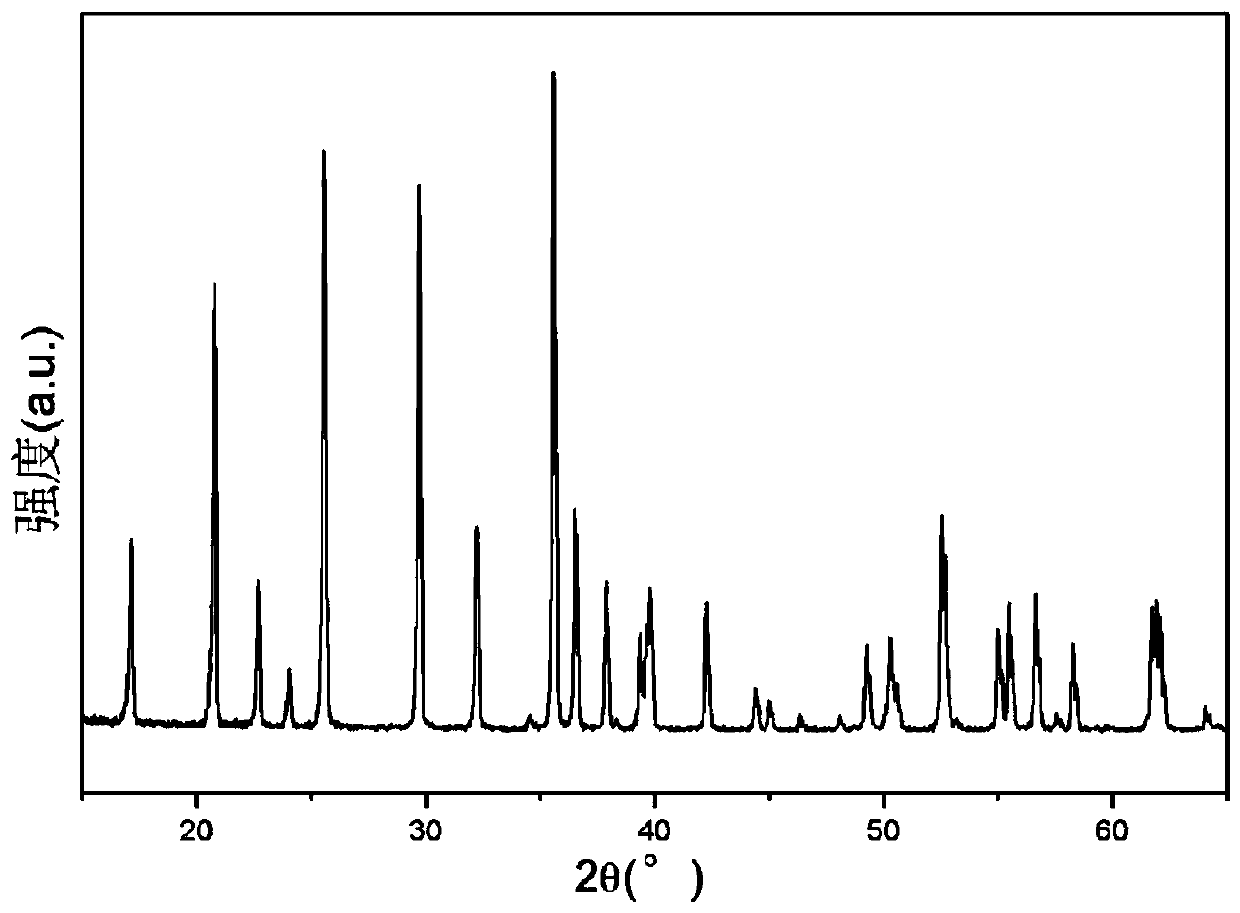

Image

Examples

preparation example Construction

[0044] A method for preparing lithium iron phosphate capable of industrialization on a large scale, the method comprising the following steps:

[0045] The step of aqueous solution preparation (abbreviation preparatory process): preparation contains the aqueous solution that concentration is 30wt% inorganic mixed acid and 10wt% contains organic acid, and inorganic mixed acid is preferably the mixture of phosphoric acid and sulfuric acid, more specifically 85wt% phosphoric acid and 98wt% concentrated sulfuric acid mixture, and the best mixing mass ratio is 10:1. More preferably, the characteristic of the organic acid described in the first reaction liquid is that it has a residual phosphorus rate of 0.1wt% or more; most preferably, the characteristic of the organic acid described in the first reaction liquid is that it also has a residual phosphorus rate of 0.1wt% % of residual carbon rate. In addition to the functions of coordinating and complexing with iron ions, controlling...

Embodiment 1

[0076] Preparation of Nano-iron Phosphate

[0077] Aqueous solution preparation process: prepare to contain the aqueous solution that concentration is 30wt% inorganic mixed acid and 10wt% containing organic acid, described mixed acid is the mixture of phosphoric acid and sulfuric acid, wherein is the mixture of 85wt% phosphoric acid and 98wt% concentrated sulfuric acid, the mass ratio of its mixing is 10:1.

[0078] Preparation of nanosheet iron phosphate

[0079] Put iron with a high-purity iron content greater than 99.8wt% into a polytetrafluoroethylene reaction tank filled with an acid solution of 30wt% inorganic mixed acid and 1wt% phytic acid, heat to 95°C, and fully react for 20 hours. At 3 o'clock, filter, demagnetize, and remove impurities to obtain a pure ferrous phosphate solution of 170g / L. Put 500L of the ferrous phosphate solution into the enamel oxidation kettle, and at the same time, add 50kg of the dissolved oxidant hydrogen peroxide into the oxidation kettle ...

Embodiment 2

[0084] Preparation of Nano-iron Phosphate

[0085] Aqueous solution preparation process: prepare to contain the aqueous solution that concentration is 30wt% inorganic mixed acid and 10wt% containing organic acid, described mixed acid is the mixture of phosphoric acid and sulfuric acid, wherein is the mixture of 85wt% phosphoric acid and 98wt% concentrated sulfuric acid, the mass ratio of its mixing is 10:1.

[0086] Preparation of Nano Spherical Iron Phosphate

[0087] Put iron with high-purity iron content greater than 99.8wt% into a reaction tank filled with 30wt% inorganic mixed acid and 5wt% phytic acid solution, heat to 90°C, fully react for 30 hours, pH = 3, filter, demagnetize, and remove impurities to obtain For ferrous phosphate solution, pour 400L of ferrous phosphate solution into the enamel oxidation kettle, and at the same time, add 58kg of hydrogen peroxide into the oxidation kettle within 15 minutes. After fully reacting, filter and wash to remove impurities, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com