Cutting device for plastic tableware production

A technology of plastic tableware and cutting device, which is applied in metal processing and other directions, can solve the problems of high cost of tableware, time-consuming and labor-consuming, cumbersome operation, etc., and achieve the effect of high degree of automation, improved cutting efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

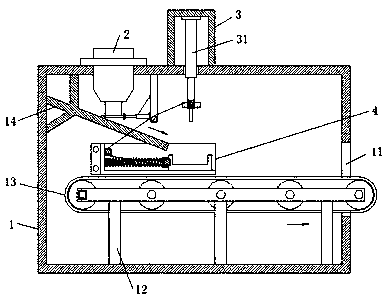

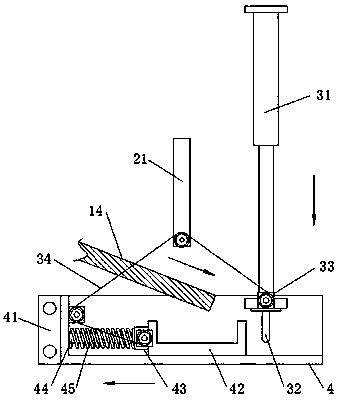

[0026] refer to Figure 1-4 , a cutting device for plastic tableware production, comprising a device body 1, a transmission mechanism, a high-efficiency press-cutting mechanism positioned above the transmission mechanism, and a feeding mechanism cooperating with the high-efficiency press-cut mechanism are arranged inside the device body 1, and the high-efficiency press-cut mechanism Including the cutting platform 4, the first driving device 31 and the linkage device, the cutting platform 4 is suspended and fixed between the inner walls of both sides through the mounting plate 41, the inside of the cutting platform 4 is slidingly installed with a discharge plate 42, and one side of the discharge plate 42 A fixed plate 43 is provided, one side of the fixed plate 43 is connected with a guide rod 44 which is flush with the discharge plate 42, a spring 45 is set on the guide rod 44, and a cutting blade is installed on the bottom piston rod of the first driving device 31 32, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com