A clean utilization process of middling coal and gangue in coal washing process

A gangue and coal washing technology, which is applied in the field of medium coal and gangue clean utilization technology, can solve the problems of insufficient separation of clean coal, etc., and achieve the effects of favorable screening, full recovery and uniform medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

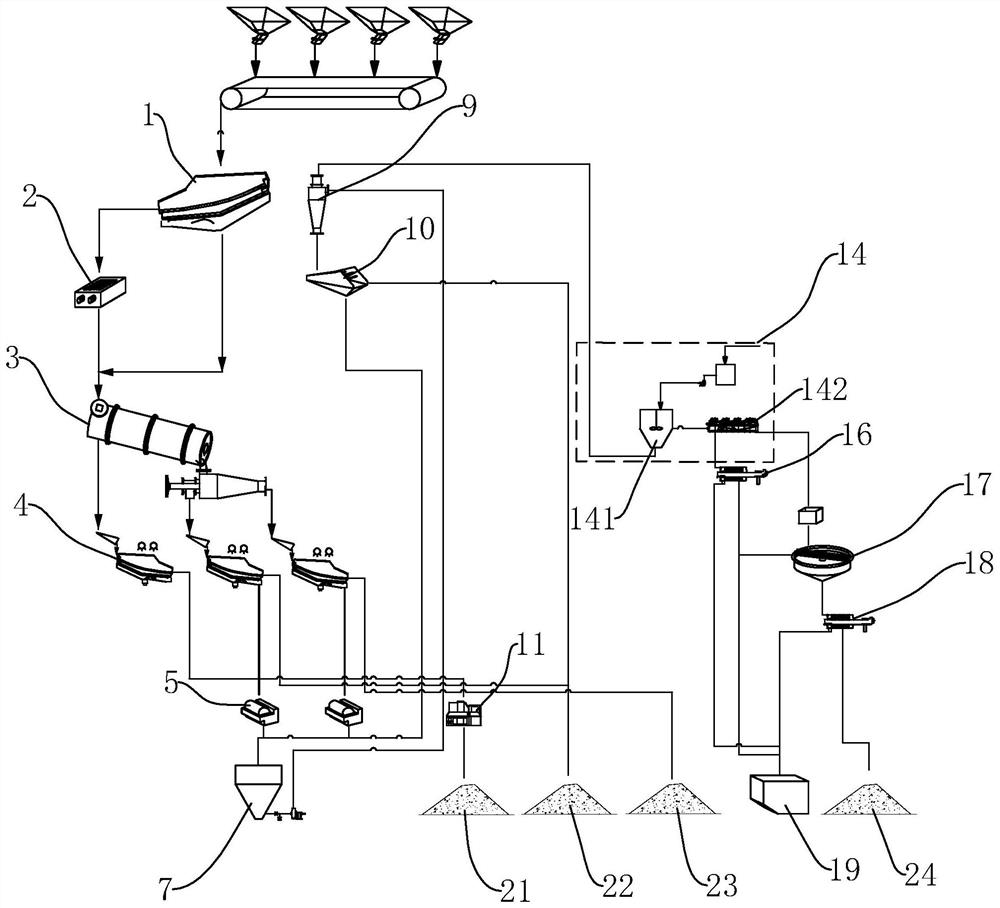

[0043] A clean utilization process of middling coal and gangue in the coal washing process, such as figure 1 As shown, step 1: feed the raw coal into the first screener 1 for screening. The first screener 1 can be a linear vibrating screen. The first screener 1 has a set value for the particle size that can pass through the sieve holes. The set value It can be 50mm, and the raw coal with a particle size greater than 50mm enters the crusher 2 for crushing.

[0044] Step 2: The raw coal crushed by the crusher 2 in step 1 and the raw coal whose particle size is smaller than the set value arrive on a conveyor belt together, and then enter the three-product dense medium cyclone 3 through the transmission belt, and the three-product dense medium cyclone 3 can It is a non-pressurized three-product dense medium cyclone 3. After that, the raw coal is sorted through the three-product dense medium cyclone 3 to separate the clean coal mixed with the coal washing medium, the medium coal m...

Embodiment 2

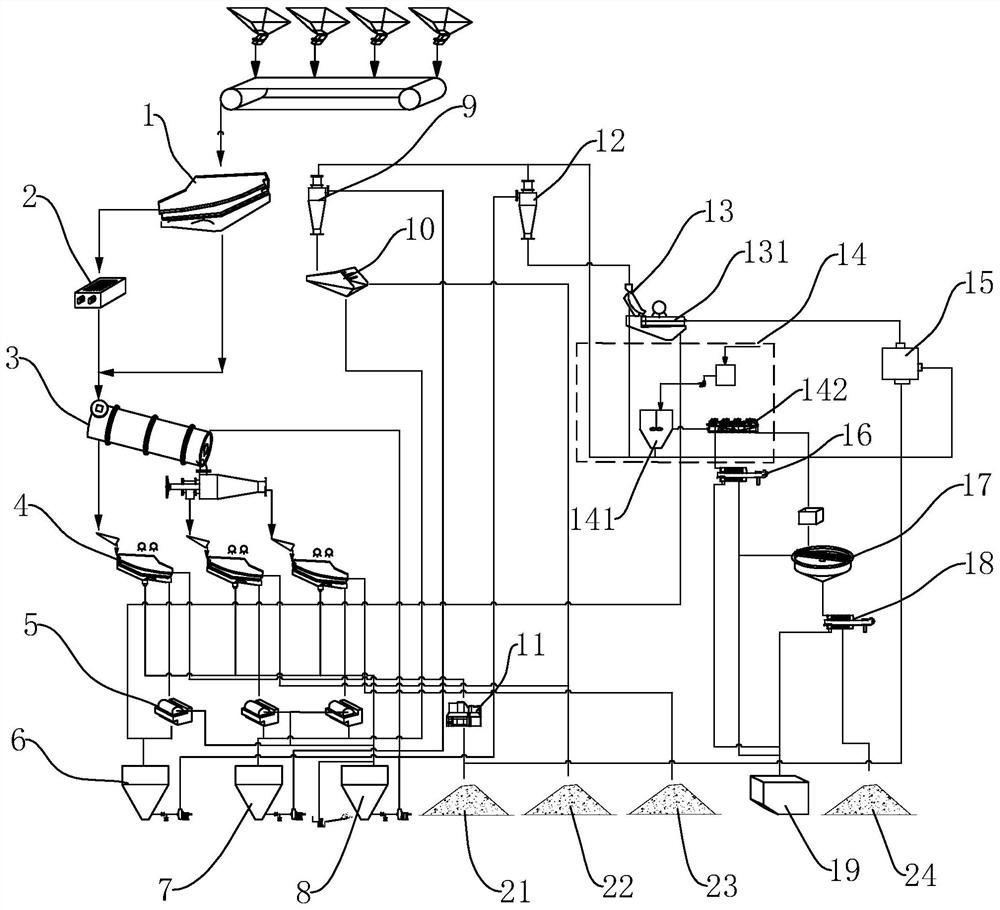

[0052] In order to improve the clean utilization of the entire coal washing process, the overall coal washing process can refer to figure 2 In step 3, the sieved water of the de-mediation screen 4 is qualified medium, and the qualified medium is recovered to the combined medium cylinder 8, and the medium in the combined medium cylinder 8 is transported to the three-product dense medium cyclone 3 by a delivery pump. As a configuration method of qualified medium, a medium adding device can be added outside the combined medium cylinder 8 to facilitate the replenishment of qualified medium; of course, a sampling valve can be set on the combined medium cylinder 8, and the qualified medium can be taken out from the sampling valve for testing , according to the test results to supplement the qualified medium.

[0053] To screen the raw coal in the three-product dense-medium cyclone 3, it is necessary to input qualified media along the tangential direction. The qualified media can be...

Embodiment 3

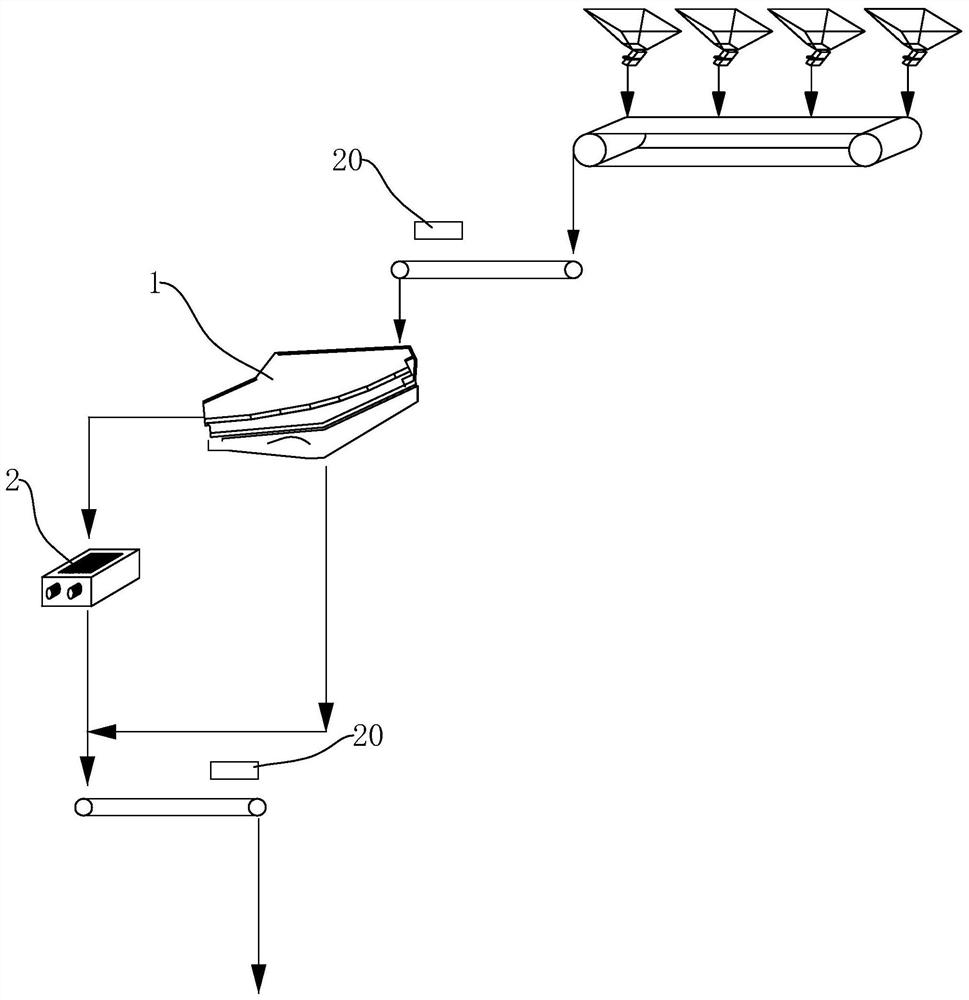

[0060] Such as image 3 As shown, in order to remove impurities such as iron in the raw coal, in step 1, the raw coal is magnetically screened using a magnet 20 before entering the first screener 1 . Of course, in order to remove more fully, the raw coal crushed by the crusher 2 in step 2 and the raw coal whose particle size is smaller than the set value can also be magnetically screened by using the magnet 20 before entering the three-product dense medium cyclone 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com