Steel bar crushing method and steel bar crushing equipment adopting same

A technology of crushing equipment and crushing methods, applied in the direction of grain processing, etc., can solve the problems of unfavorable steel scrap utilization, long length, low efficiency, etc., and achieve the effects of good adaptability, improved efficiency and quality, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

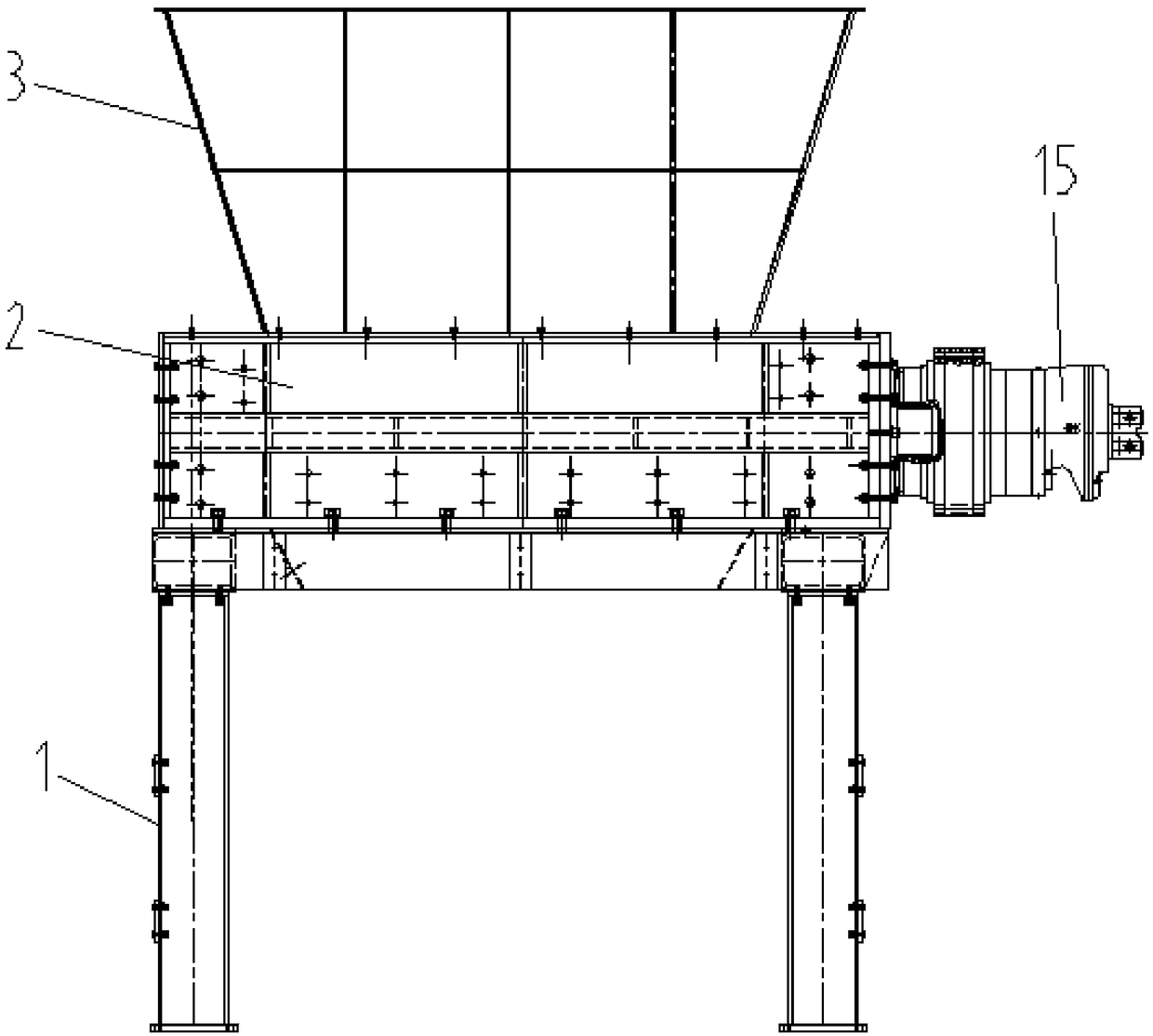

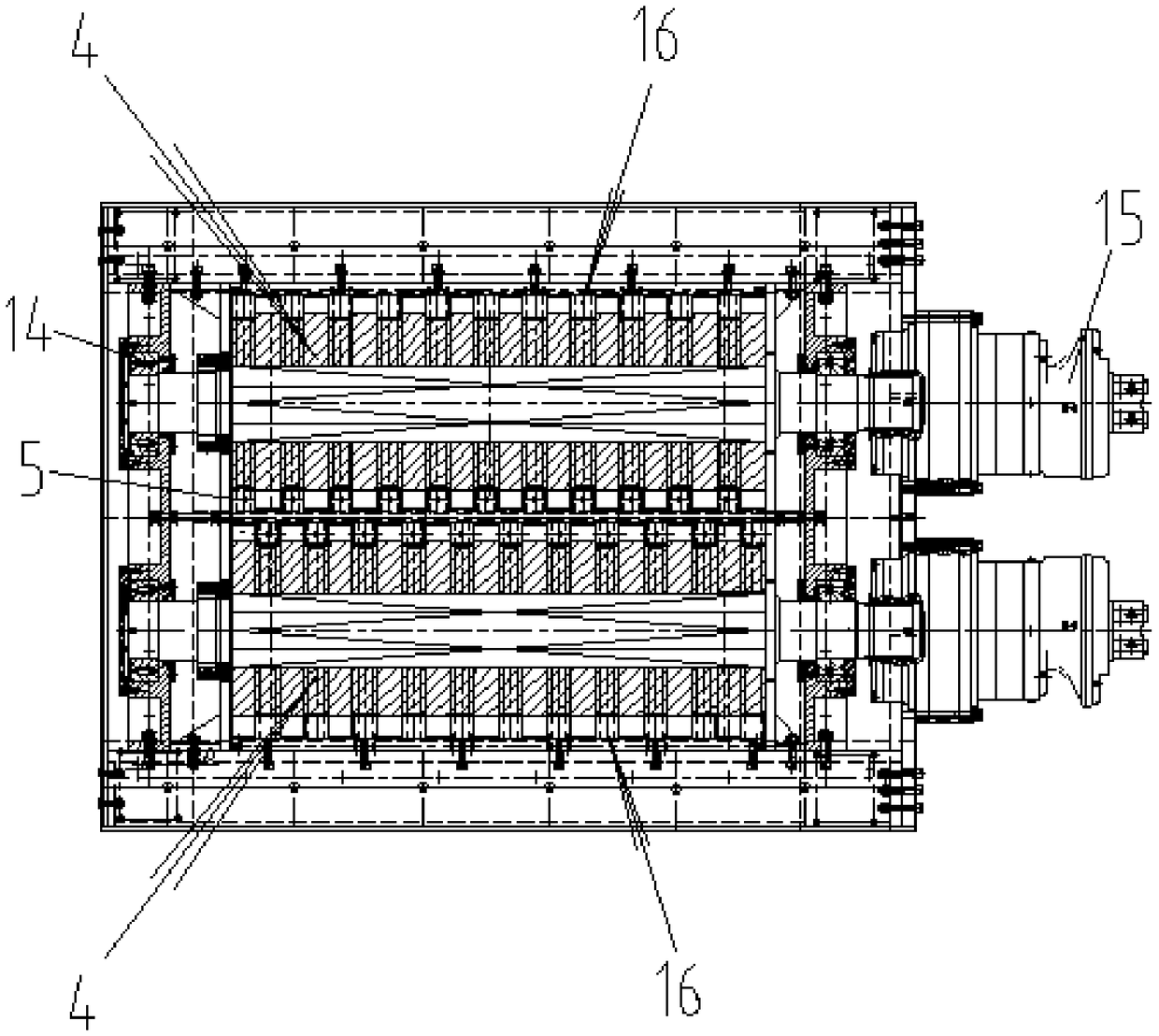

[0060] Such as Figures 1 to 5 Shown is the embodiment of a kind of steel bar crushing method of the present invention, comprises following method:

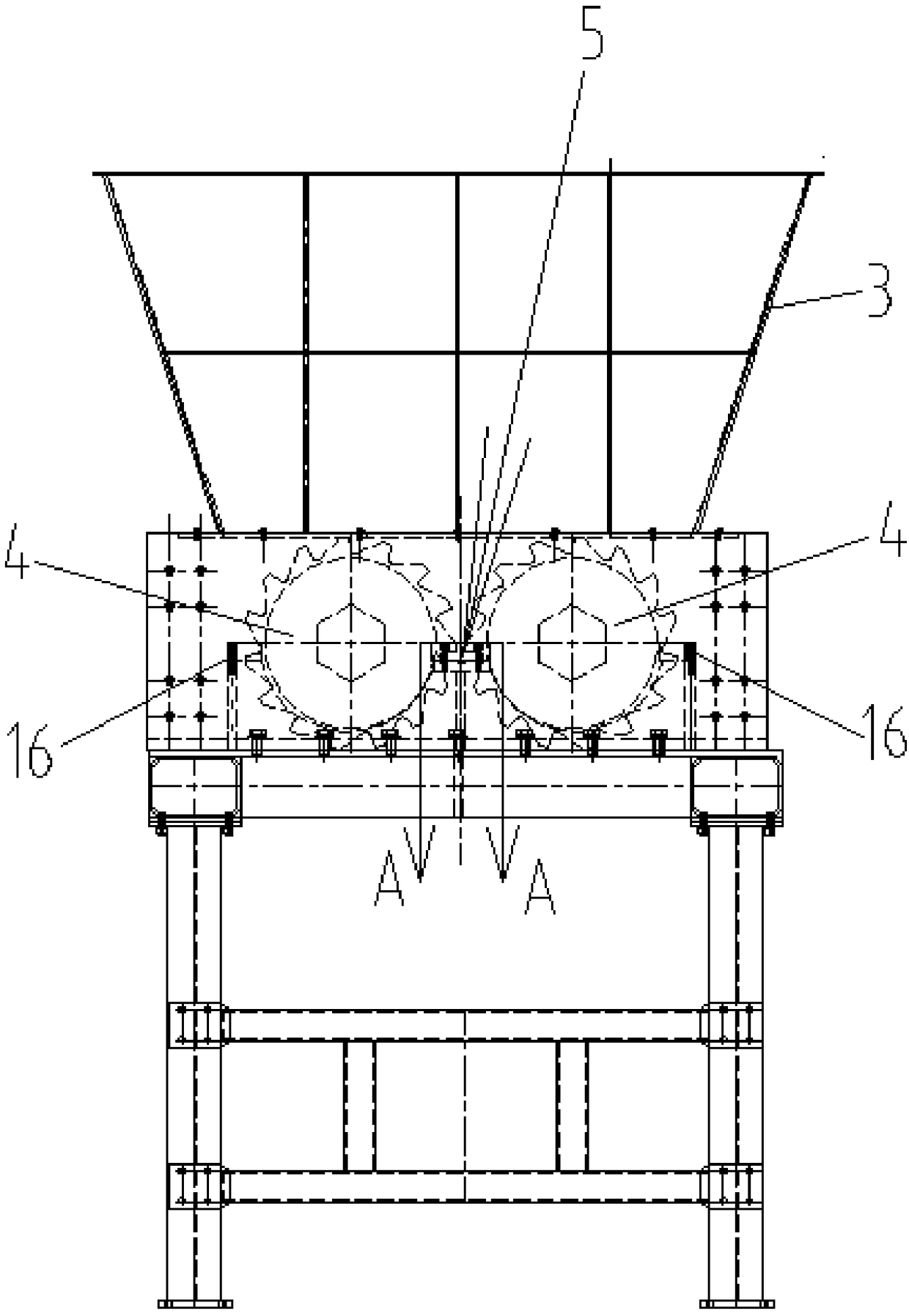

[0061] (1), a pair of rotating knife shafts 4 and a main shearing knife seat 5 are arranged, and a pair of rotating knife shafts 4 are placed on both sides of the main shearing knife seat 5;

[0062] (2), cutterhead 7 is set on rotary cutter shaft 4, shearing knife tooth 8 is set on cutterhead 7, groove 9 that runs through up and down for shearing is set on main shearing knife seat 8, shearing knife The tooth width sides and tooth tops of the tooth 8 are respectively matched with the sides of the groove 9 for shearing and the bottom of the groove 9;

[0063] (3), drop steel bar downwards from the upper part of the main shearing knife holder 5, so that the steel bar falls between a pair of rotating knife shafts 4;

[0064] (4), the rotary cutter shaft 4 rotates, and the shearing knife teeth 8 on the rotary cutter shaft 4 hook th...

Embodiment 2

[0071] Such as Figures 1 to 5 Shown is an embodiment of a steel bar crushing equipment of the present invention, including a crushing chamber 2, a feeding hopper 3 connected above the crushing chamber 2, and a rotatable device for shearing and crushing steel bars is arranged in the crushing chamber 2. A pair of rotary cutter shafts 4, a main shearing knife seat 5 compatible with the pair of rotary cutter shafts 4 is fixedly arranged between the pair of rotary cutter shafts 4, and the rotary cutter shafts 4 include a rotating shaft 6 and a certain number of cutterheads 7 arranged on the rotating shaft 6 and distributed at intervals, the cutterhead 7 is provided with a number of shearing teeth 8 along the circumferential direction, and the main shearing knife seat 5 is provided with The tooth width sides of the shearing knife teeth 8 are matched with grooves 9 at the tops of the teeth, and the grooves 9 are vertically connected.

[0072] During work, the scrap steel bars are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com