A kind of magnetic polyimide composite material and its preparation method and application

A polyimide and composite material technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of less application in the field of pretreatment, achieve low cost, good dispersion, reduce difficulty and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

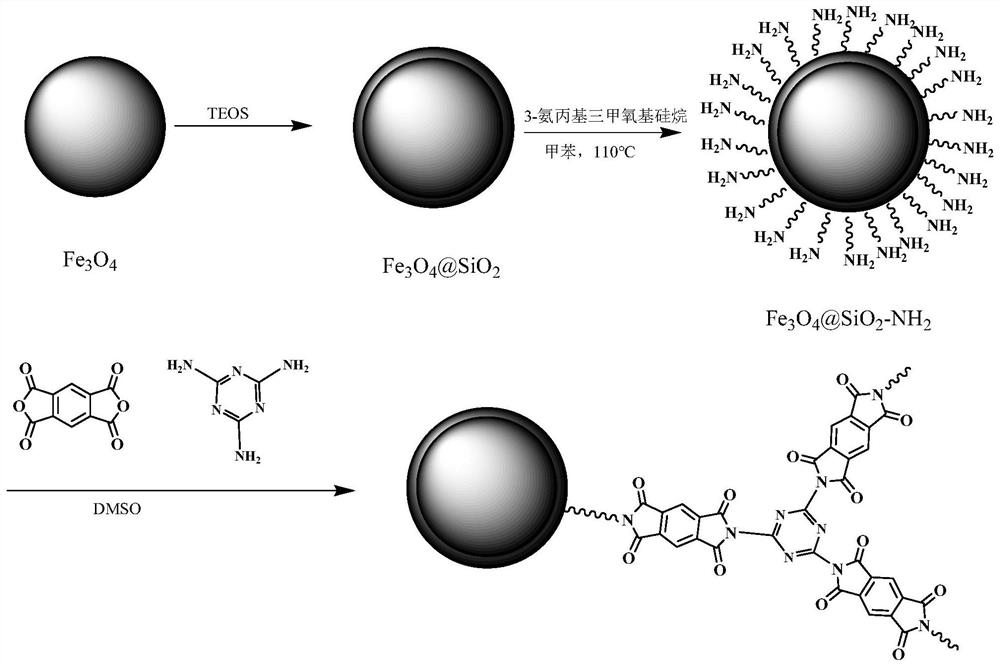

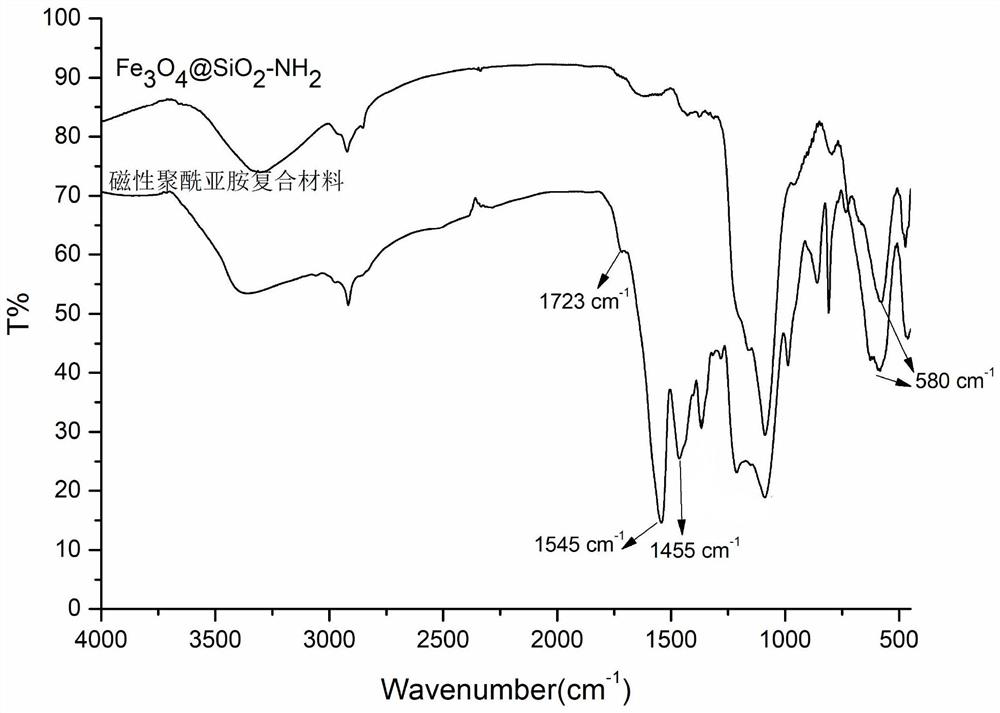

[0037] Embodiment 1, the preparation of magnetic polyimide composite material

[0038] A preparation method of magnetic polyimide composite material, comprising the following steps:

[0039] (1) Magnetic Fe 3 o 4 Synthesis of nanoparticles:

[0040] Weigh 1.2g FeCl 3 ·6H 2 O solid in a 100mL beaker, add 30mL of ethylene glycol, sonicate to dissolve it into a transparent solution, then add 3.5g of anhydrous sodium acetate and 0.8g of polyethylene glycol, sonicate for 15min; transfer to a 200mL high-pressure reaction In the kettle, react at 200°C for 15 hours, and wash the Fe produced by the reaction with ethanol and ultrapure water in sequence. 3 o 4 , repeated three times, after vacuum drying at 60°C for 12 hours, magnetic Fe with good monodispersity can be obtained 3 o 4 Nanoparticles, stored in a desiccator for subsequent use;

[0041] (2) Magnetic Fe 3 o 4 @SiO 2 Synthesis of particles:

[0042] Weigh 1.0g Fe 3 o 4 In a 250mL three-necked round-bottomed flask...

Embodiment 2

[0052] Embodiment 2, the adsorption performance test of polyimide composite material:

[0053] 1. Adsorption of rhodamine B compounds

[0054] The specific method is:

[0055] Take Fe 3 o 4 @SiO 2 , Fe 3 o 4 @SiO 2 -NH 2 1. Each 2 mg of magnetic polyimide composite material was added to 5 mL of rhodamine B standard solution (concentration: 1 μg / mL), ultrasonically adsorbed for 5 min, passed through a microporous membrane, and injected. Compare the adsorption capacity of each synthesized magnetic material to rhodamine B compound, such as Figure 6 shown. Experiments have shown that the magnetic polyimide composite material has the best adsorption capacity for rhodamine B. This is because the modified polyimide layer not only has a large specific surface area and unique pore size, but also can provide multiple interactions such as π-π, hydrophobicity, hydrogen bonding, and weak cation exchange.

[0056] Take 2 mg of magnetic polyimide composite material, add 5 mL of R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com