A fluorine-containing thin film solar cell front film and a manufacturing process thereof

A technology of solar cells and manufacturing processes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as insufficient material selection, insufficient UV resistance and water resistance of products, material requirements or manufacturing processes that have not been mentioned, and achieve Improve the safety of use, good insulation, high water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention is described further below:

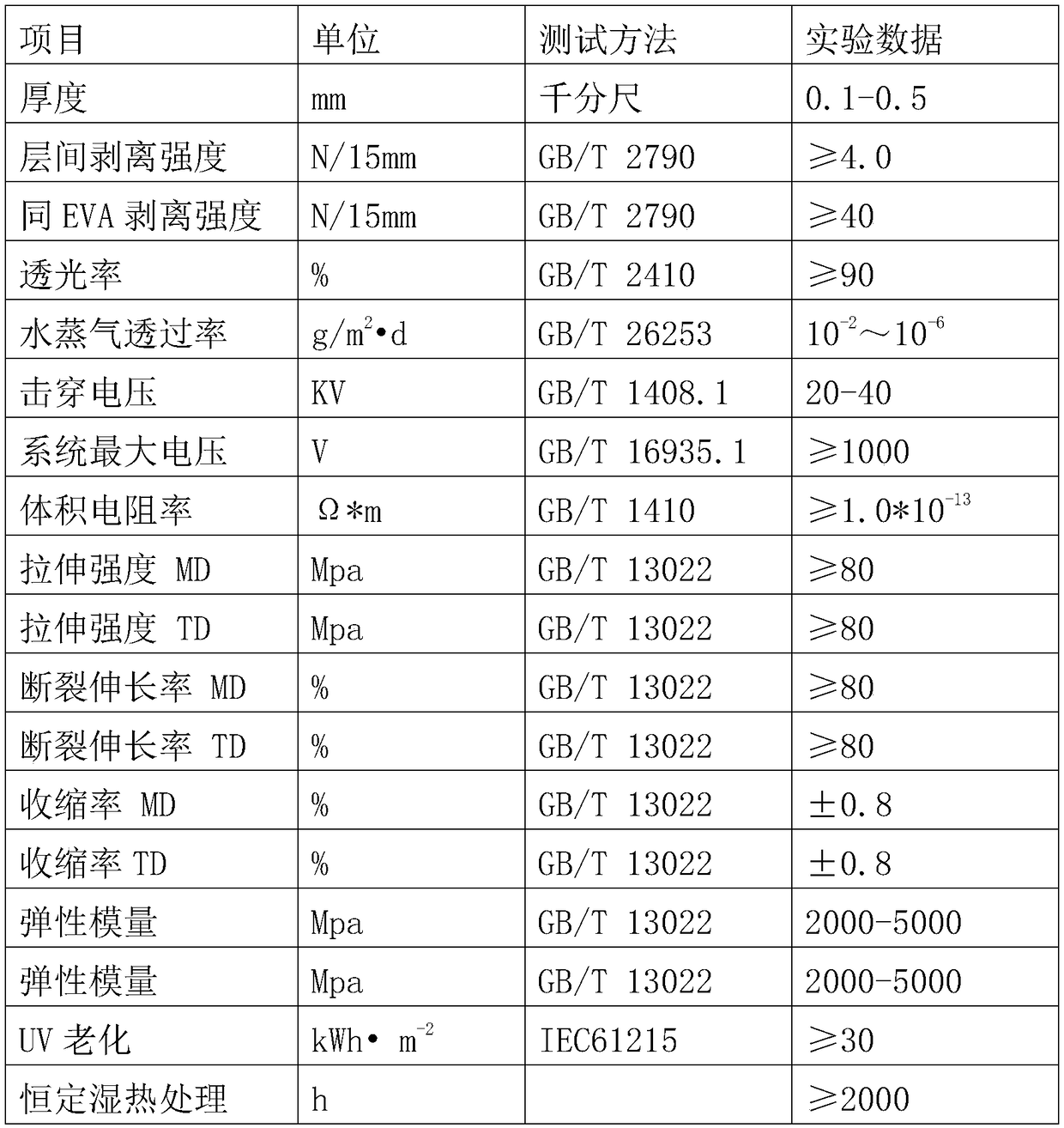

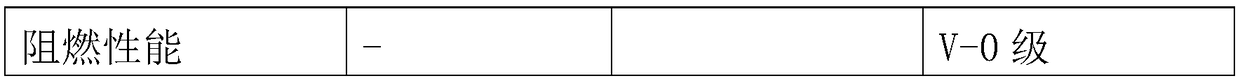

[0026] A front film of a fluorine-containing thin-film solar cell, comprising a fluorine-containing material film layer, an adhesive layer, an inorganic deposition layer, and an insulating layer. The fluorine-containing material film layer, adhesive layer, inorganic deposition layer, and insulating layer The layers are arranged sequentially from top to bottom, the fluorine-containing material film layer includes at least one of PVDF, PFA, ETFE, and EFEP, and the inorganic deposition layer includes at least one of silicon dioxide, aluminum oxide, and titanium dioxide, The insulating layer includes at least one of PET and PBT. The adhesive layer includes at least one of polyester adhesive and polyurethane adhesive, and the water vapor permeability of the battery front film is 10 -2 ~10 -6 g / m 2 d, the optical transmittance of the battery front film is ≥90%, and the ultraviolet aging performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com