Secondary reheat type solar energy and coal-fired power plant complementary power generation system and operation method

A technology for secondary reheating and coal-fired power plants, applied in solar thermal power generation, solar heating systems, solar thermal energy, etc. Coal system power generation efficiency and other issues, to achieve the effect of dynamic optimization of heat distribution and heat balance, improve energy grade and work ability, and improve light-to-heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

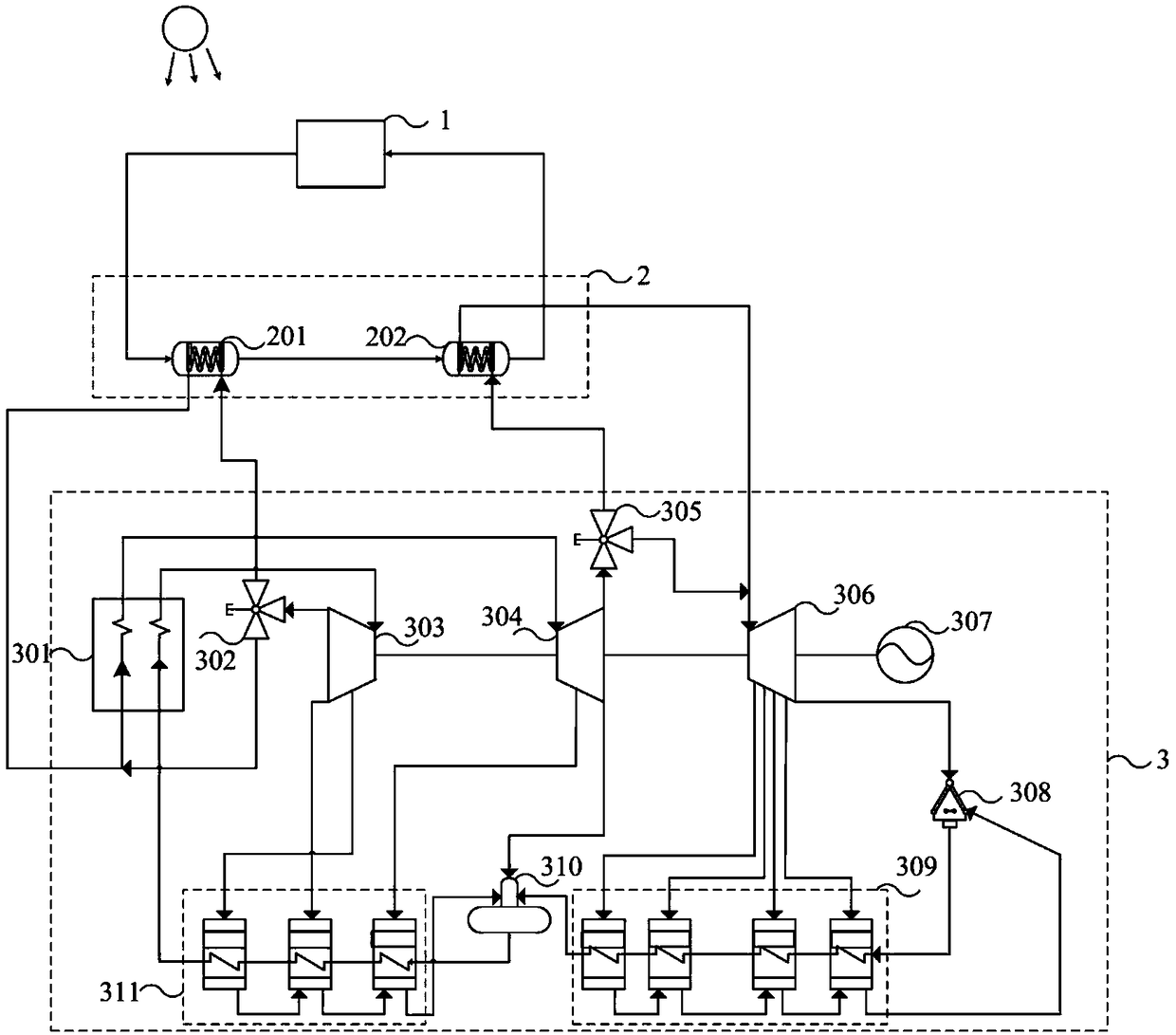

[0035] Such as figure 1As shown, the present invention provides a complementary power generation system of double reheating solar energy and coal-fired power station, which includes a solar heat collection field 1 , a steam heating subsystem 2 and a coal-fired power generation subsystem 3 .

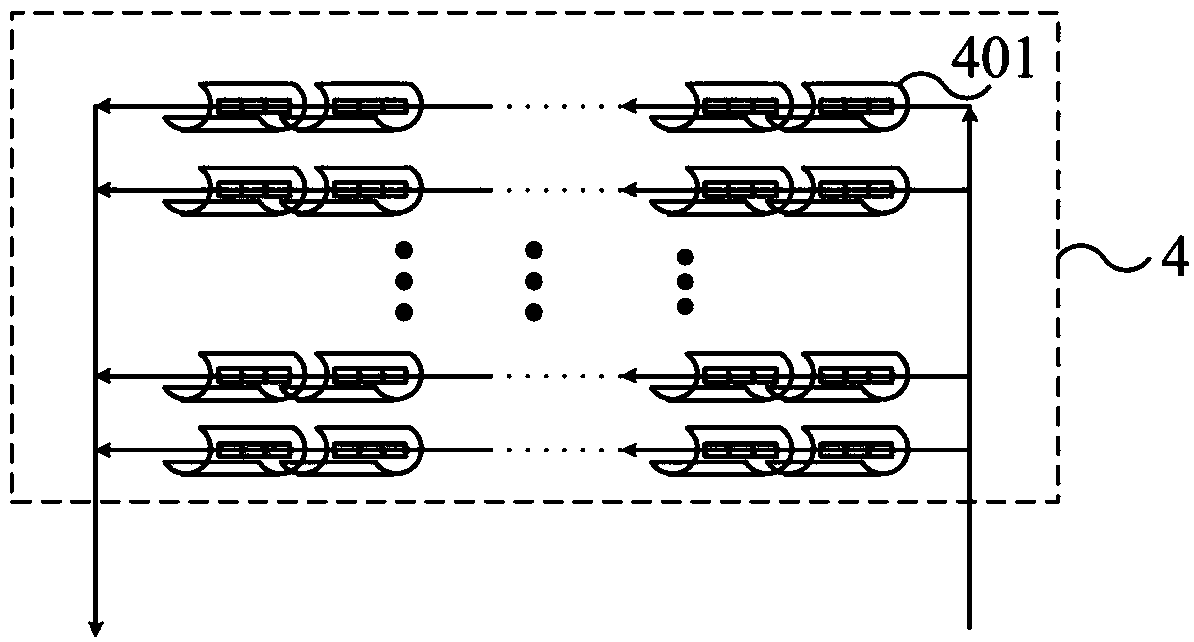

[0036] The solar heat collection field 1 is a trough-type solar heat collection field 4, and the trough-type solar heat collection field 4 is composed of several solar heat collectors 401 connected in series and then connected in parallel to heat the heat exchange fluid. In this embodiment, the steam heating subsystem 2 is cooperatively connected with the high-temperature heat exchange fluid delivery pipe of the solar heat collection field 1, and the solar heat collected by the solar heat collection field 1 passes through the steam heating system 2 and simultaneously heats part of the coal-fired power generation system 3 to regenerate. Hot steam and part of the medium pressure cylinder ex...

Embodiment 2

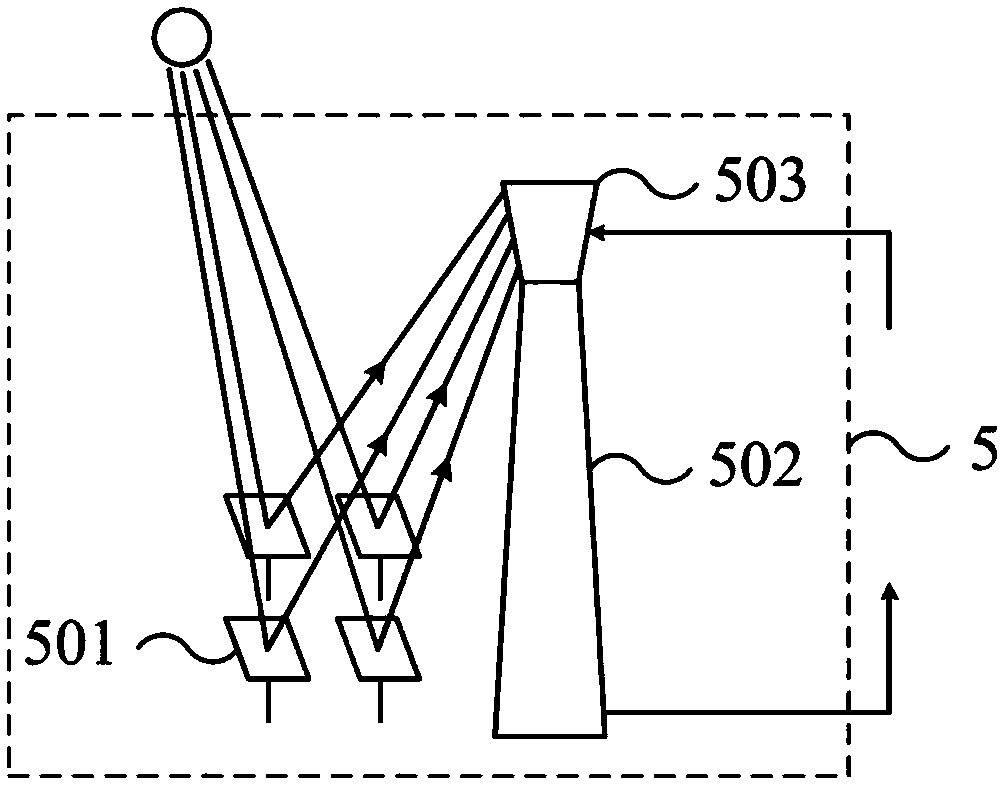

[0048] The difference between Embodiment 2 and Embodiment 1 is that the solar heat collection field 1 adopts a tower-type solar heat collection field 5, and the heliostat 501 reflects sunlight to the heat absorber 503, and the heat absorber 503 transfers heat energy to the heat absorption tower 502 , the heat absorption tower 502 transfers the high-temperature heat exchange fluid to the high-temperature steam heater 201 and the low-temperature steam heater 202 in sequence, and other operating steps are the same as in Embodiment 1.

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 2 and embodiment 1 is only that the solar heat collecting field 1 adopts the linear Fresnel solar heat collecting field 6, and other operation steps are the same as those of embodiment 1 and embodiment 2.

[0051] Wherein, the solar heat collection field 1 can be a trough type solar heat collection field 4 , a tower type solar heat collection field 5 or a linear Fresnel solar heat collection field 6 , or any combination of the above three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com