Preparation method of superamphiphobic SiO2 nano functional solution and application

A nano-functional, super-amphiphobic technology, applied in the direction of biocide-containing paints, coatings, anti-corrosion coatings, etc., can solve problems such as difficult and low-cost mass production, complex operation process, and harsh experimental conditions, and achieve great social value and economic value, simple process and controllable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The embodiment of the present invention provides a super amphiphobic SiO 2 The preparation method of nano functional liquid comprises the following steps:

[0033] S1, add alkaline catalyst and silicate in alcoholic solvent, stir, react and age to prepare SiO 2 A dispersion of nanoparticles; the alcoholic solvent is one or more of ethanol, methanol, and isopropanol, preferably ethanol.

[0034] The basic catalyst is one or more of NaOH aqueous solution, KOH aqueous solution, ammonia water and ethylenediamine, wherein: the concentration of NaOH aqueous solution or KOH aqueous solution is between 0.2-5 mol / liter, and NaOH or KOH and alcohols The molar ratio of solvents is between 1:1000 and 1:200; the volume ratio of ammonia or ethylenediamine to alcohol solvents is between 1:5 and 1:20.

[0035] The silicate is one or both of tetrabutyl orthosilicate and tetraethyl orthosilicate.

[0036] The aging time is 1-7 days, preferably 4 days. The preparation of SiO 2 The re...

Embodiment 2

[0042] The embodiment of the present invention provides a super amphiphobic SiO 2 The preparation method of nanometer functional liquid, comprises the steps:

[0043] (1) SiO 2 Preparation of nanoparticle dispersion: add 5 ml of concentrated ammonia water to 60 ml of methanol at room temperature, then add 10 ml of tetraethyl orthosilicate (TEOS), stir for 3 hours, and age for 1 day.

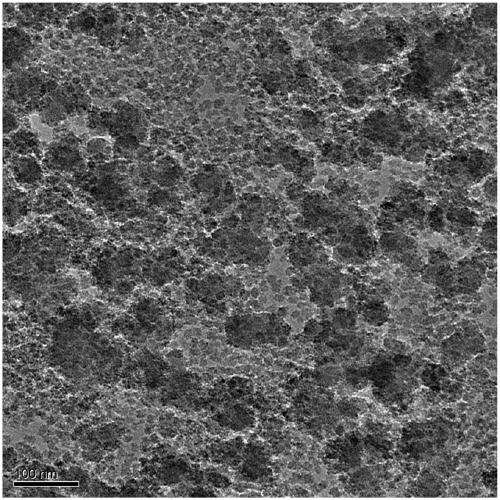

[0044] see figure 1 As shown, the transmission electron microscope test results show that the SiO prepared in this embodiment 2 The average size of nanoparticles is about 18nm, and these small particles tend to form aggregates with an average diameter of about 60-100nm, which helps to form a secondary structure when preparing a film and helps to improve hydrophobic performance.

[0045] (2) SiO prepared in step (1) under stirring at room temperature 2 Add 0.6ml of 1H,1H,2H,2H-perfluorooctyltriethoxysilane to the nanoparticle dispersion, and react for 4 hours to obtain superamphiphobic SiO 2 ...

Embodiment 3

[0048] The embodiment of the present invention provides a super amphiphobic SiO 2 The preparation method of nanometer functional liquid, comprises the steps:

[0049] (1) SiO 2 Preparation of nanoparticle dispersion: 3.5 ml of ethylenediamine was added to 50 ml of methanol at room temperature, and then 10 ml of tetraethyl orthosilicate (TEOS) was added, stirred for 3 hours, and aged for 4 days.

[0050] (2) SiO prepared in step (1) under stirring at room temperature 2 Add 1H, 1H, 2H, 2H-perfluorodecyltrimethoxysilane to the nanoparticle dispersion to 0.8ml, and react for 5 hours to obtain superamphiphobic SiO 2 Nano functional liquid.

[0051] see Figure 4 As shown, using the super-amphiphobic SiO2 nano-functional liquid by spray coating on the surface of the ceramic tile, the static contact angle of the film product obtained with water is 166.9 degrees, and the rolling angle is 2.3 degrees; see Figure 5 As shown, the static contact angle of the obtained superamphiphobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com