Waste-free and full-utilization method for preparing foliar fertilizer by using phosphorus-potassium method

A foliar fertilizer, phosphorus and potassium technology, applied in the field of foliar fertilizer preparation by phosphorus and potassium method, can solve pollution and other problems, achieve the effect of increasing NPK content, solving industrial problems, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

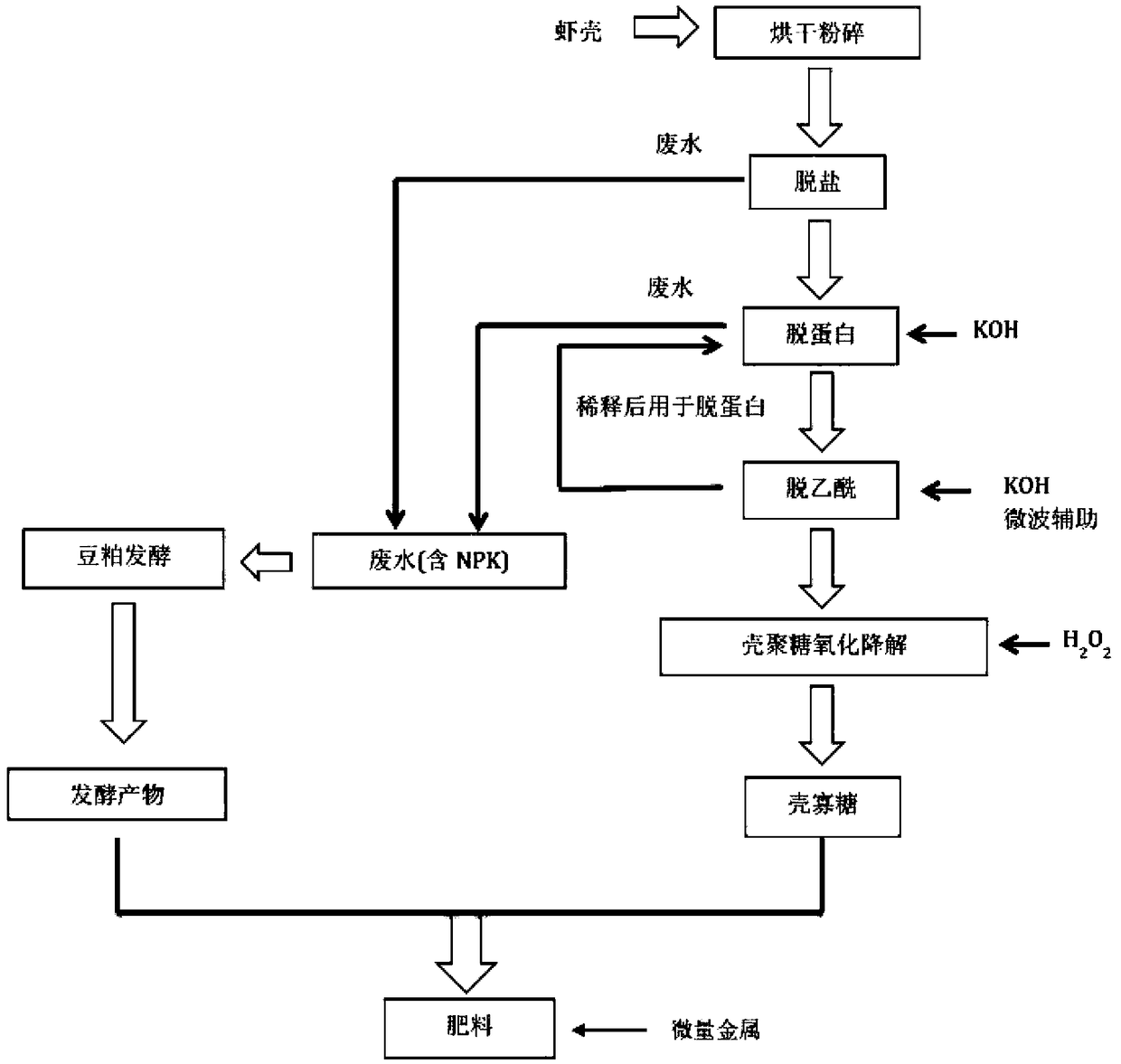

[0047] A method for preparing foliar fertilizers by using the phosphorus and potassium method without waste, such as figure 1 shown, including the following steps:

[0048] (1) extract chitin:

[0049] Shrimp shells were dried and crushed to 100 mesh, 100 g was taken, and 1 L of phosphoric acid solution with a mass concentration of 4% was added according to the material ratio of 1:10, reacted at room temperature for 30 minutes, and centrifuged at 4800 r / min for 15 minutes to obtain supernatant 1 and precipitate 1;

[0050] Add 1L of potassium hydroxide solution with a mass concentration of 4% in the precipitation 1 according to the material ratio of 1:10, react at 70°C for 60 minutes, and centrifuge at 4800r / min for 15 minutes to obtain the supernatant 2 and chitin;

[0051]The chitin was dried, and the supernatant liquid 1 and the supernatant liquid 2 were mixed uniformly at a volume ratio of 1:1 to obtain a waste liquid mixture.

[0052] (2) prepare chitosan:

[0053] Tak...

Embodiment 2

[0069] (1) extract chitin:

[0070] Shrimp shells were dried and crushed to 100 mesh, 100 g was taken, and 600 mL of phosphoric acid solution with a mass concentration of 3% was added according to the material ratio of 1:6, reacted at room temperature for 30 min, and centrifuged at 4800 r / min for 15 min to obtain supernatant 1 and precipitate 1;

[0071] Add 600mL of potassium hydroxide solution with a mass concentration of 3% in precipitation 1 according to the material ratio of 1:6, react at 70°C for 30 minutes, and centrifuge at 4800r / min for 15 minutes to obtain supernatant 2 and chitin;

[0072] The chitin was dried, and the supernatant liquid 1 and the supernatant liquid 2 were mixed uniformly at a volume ratio of 1:1 to obtain a waste liquid mixture.

[0073] (2) prepare chitosan:

[0074] Take 1g of dried chitin, add 15mL of potassium hydroxide solution with a mass fraction of 45% according to the material ratio of 1:15, react with microwave at 600W for 8min, and cent...

Embodiment 3

[0090] Dilute the foliage fertilizer obtained in Examples 1 and 2 by 200 and 400 times respectively, spray cucumber seedlings, spray once every 5 days, and apply 2 times in total, manage normally after spraying, harvest and weigh after maturity . As shown in Table 3, compared with the application of foliar fertilizers sold in the market, the foliar fertilizers in Examples 1 and 2 can effectively increase the cucumber yield.

[0091] Table 3. Effect of foliar fertilizer application

[0092]

[0093]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com