High temperature resistant optical fiber and preparation method thereof

A technology of high temperature resistance and optical fiber, which is applied in the direction of cladding optical fiber, glass optical fiber, optical waveguide and light guide, etc. It can solve the problems of affecting the geometric parameters of optical fiber, not suitable for long-distance use, and large transmission loss of optical fiber, so as to achieve low and reliable optical fiber transmission loss Optical fiber transmission performance, stable and consistent effect of diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

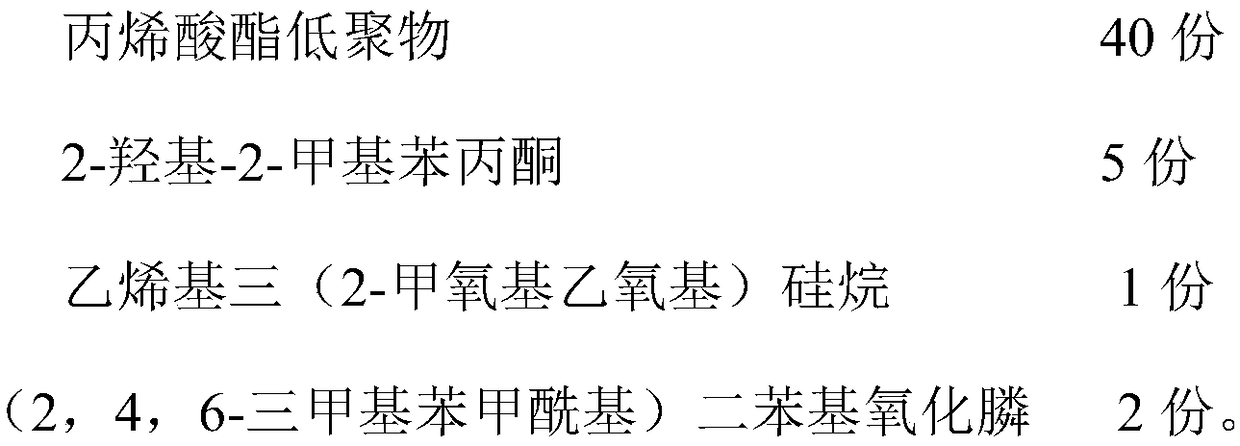

Embodiment 1

[0054] The high temperature resistant optical fiber of this embodiment is prepared by the following process:

[0055] (1) Put the online rod and polished rod in the graphite furnace for high-temperature melting and drawing at 2000°C, and the speed is controlled at 2200m / min, allowing a certain error in the diameter of the polished rod;

[0056] (2) After the melted and drawn optical fiber is annealed and cooled at room temperature, it directly enters the double-coated mold for one-time coating. The PSU system controls the matching of the gas and speed at the melting end of the optical rod, and the adjustment of the mold can control different coatings. coating diameter, the coating pressure of the inner coating is 2.5bar, the coating pressure of the outer coating is 5bar, and the coating temperature is 40°C;

[0057] (3) The coated optical fiber is cured under the high power of 6 UV lamps;

[0058] (4) A high temperature resistant optical fiber with a diameter of 200 μm was pr...

Embodiment 2

[0064] The high temperature resistant optical fiber of this embodiment is prepared by the following process:

[0065] (1) Put the online rod and polished rod in a graphite furnace for high-temperature melting and drawing at 2200°C, and the speed is controlled at 2100m / min, allowing a certain error in the diameter of the polished rod;

[0066] (2) After the melted and drawn optical fiber is annealed and cooled at room temperature, it directly enters the double-coated mold for one-time coating. The PSU system controls the matching of the gas and speed at the melting end of the optical rod, and the adjustment of the mold can control different coatings. coating diameter, the coating pressure of the inner coating is 1 bar, the coating pressure of the outer coating is 4.5 bar, and the coating temperature is 35°C;

[0067] (3) The coated optical fiber is cured under the high power of 5 UV lamps;

[0068] (4) A high temperature resistant optical fiber with a diameter of 200 μm was pr...

Embodiment 3

[0074] The high temperature resistant optical fiber of this embodiment is prepared by the following process:

[0075] (1) Put the online rod and polished rod in the graphite furnace for high-temperature melting and drawing at 1900°C, and the speed is controlled at 2000m / min, allowing a certain error in the diameter of the polished rod;

[0076] (2) After the melted and drawn optical fiber is annealed and cooled at room temperature, it directly enters the double-coated mold for one-time coating. The PSU system controls the matching of the gas and speed at the melting end of the optical rod, and the adjustment of the mold can control different coatings. coating diameter, the coating pressure of the inner coating is 3bar, the coating pressure of the outer coating is 5.5bar, and the coating temperature is 45°C;

[0077] (3) The coated optical fiber is cured under the high power of 6 UV lamps;

[0078] (4) A high temperature resistant optical fiber with a diameter of 245 μm was pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| additional attenuation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com