A laser additive device and method for additive manufacturing thereof

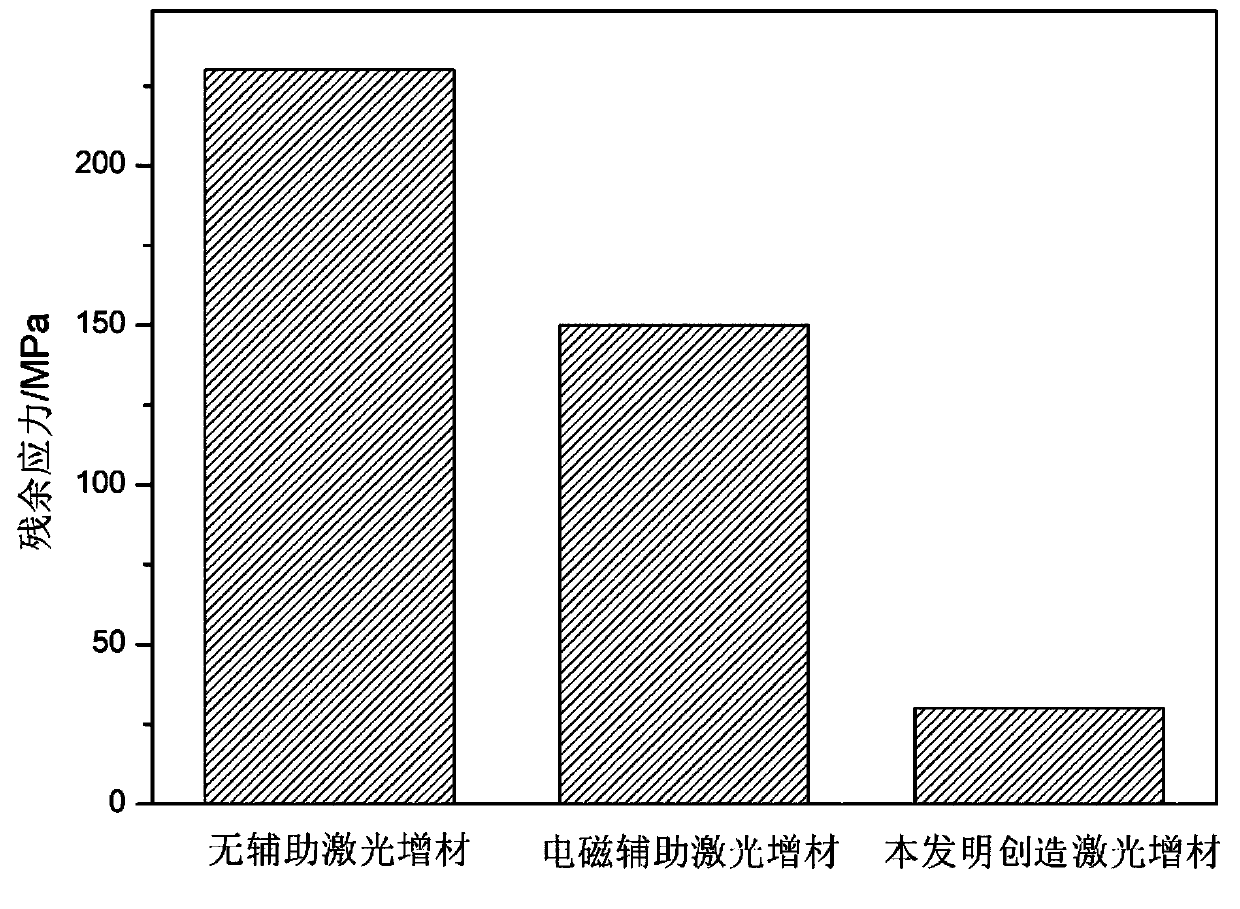

A laser additive and laser device technology, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement, can solve the problems of inability to discharge gas, segregation of molten pool elements, and uneven structure, and achieves suppression of metallurgical defects, energy and energy. And the effect of uniform distribution of temperature field and uniform stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

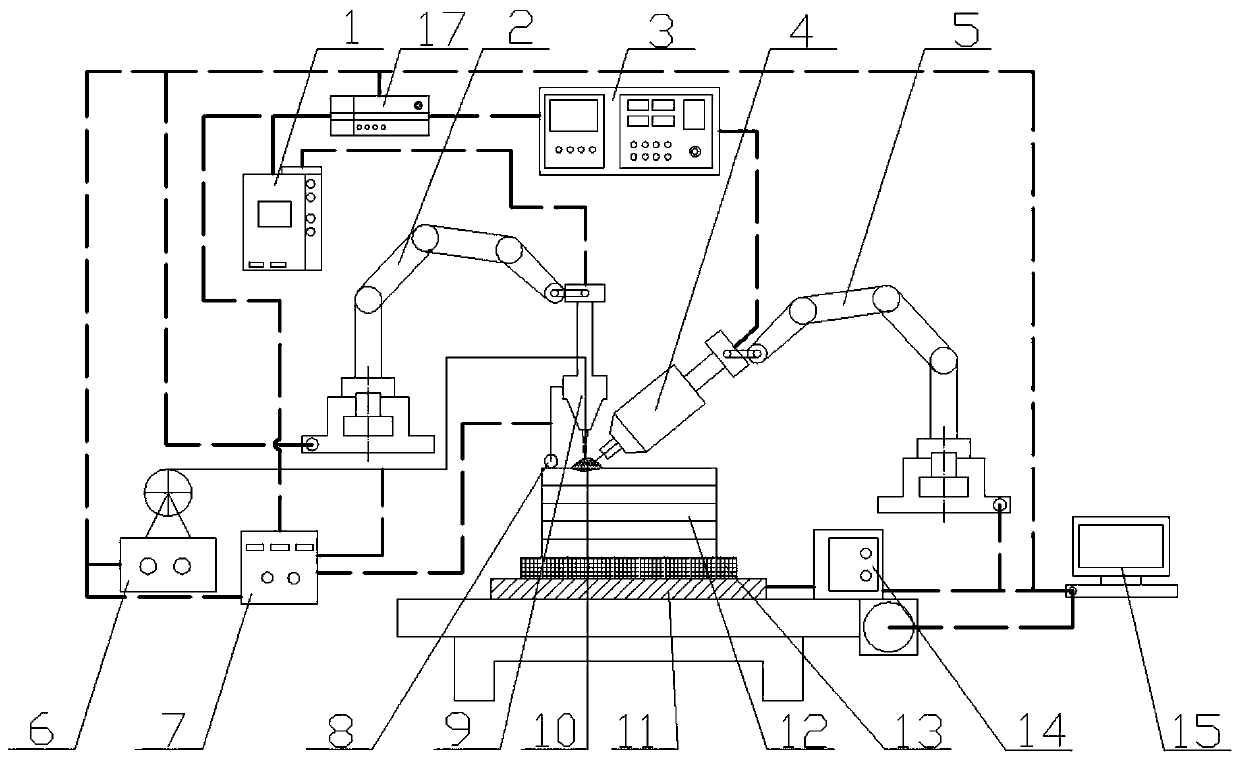

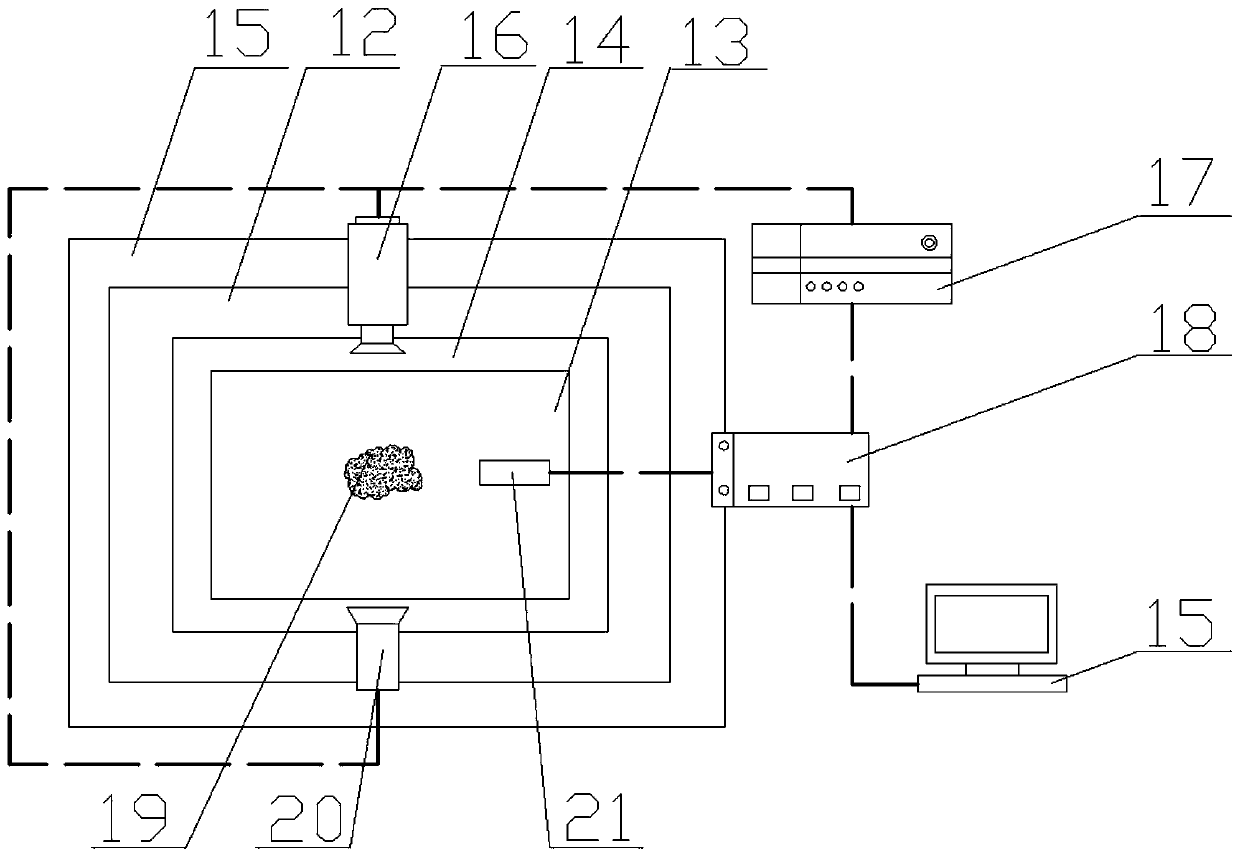

[0041] Such as figure 1 and figure 2 As shown, the laser additive device of the present invention includes a rotating beam laser device, a high-frequency short-pulse laser device, an auxiliary current device, an information collection system, a high-frequency induction heating system, and a control computer 15 .

[0042] The rotating beam laser device comprises a continuous laser generator 1, a first high-precision mechanical arm 2, a wire feeder 6 and a continuous laser head 9; the continuous laser generator 1 is connected to the continuous laser head 9 to provide Continuous laser light source; the optical rotation module is built in the laser head 9 of the continuous laser, and the laser beam generates a rotating beam during the emission process; the laser head 9 of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com