Method of preparing high-efficiency photocatalytic composite material

A composite material and photocatalytic technology, which is applied in the field of preparation of high-efficiency photocatalytic composite materials, can solve the problems of no adsorption performance, no firm fixation, large pores between fibers, etc., to avoid a large number of shedding, improve mechanical properties, and improve adsorption performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

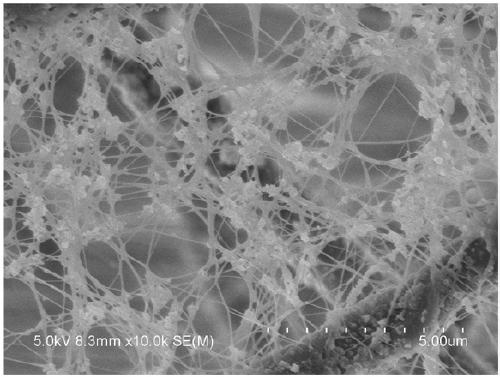

[0029] 1. Tryptone, yeast powder and mannitol are configured nutrient solution according to mass ratio 4.5:3:25.5; 2 ) in nano-TiO with a concentration of 1g / L 2 Immerse in the suspension for 60min.

[0030] 2. Pour 180mL of nutrient solution and soaked sample into a 500mL Erlenmeyer flask, seal and sterilize in an autoclave at 126°C and 0.15MP for 1 hour.

[0031] 3. In the biological safety cabinet, use a pipette gun to pipette 10mL of the original bacterial solution into the cooled nutrient solution. Then, the inoculated nutrient solution was placed in a shaker incubator for static culture for 4 days.

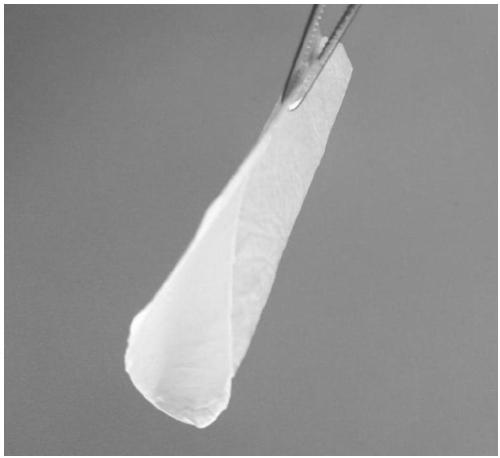

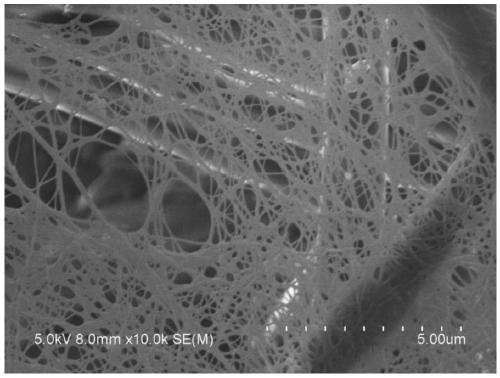

[0032] 4. Take out the cultured composite bacterial cellulose, wash it with deionized water, put it into 0.11mol / L NaOH solution, and boil it in alkali for 10 hours in a water bath at 80°C to remove residual culture medium and bacteria. After the alkali boiling is finished, the bacterial cellulose is rinsed again with deionized water until it becomes neutral, and then put...

Embodiment 2

[0035] 1. Tryptone, yeast powder and mannitol are configured nutrient solution according to mass ratio 4.5:3:25.5; 2 ) at a concentration of 2g / L nano-TiO 2 Immerse in the suspension for 30min.

[0036] 2. Pour 180mL of nutrient solution and soaked sample into a 500mL Erlenmeyer flask, seal and sterilize in an autoclave at 126°C and 0.15MP for 1 hour.

[0037] 3. In the biological safety cabinet, use a pipette gun to pipette 10mL of the original bacterial solution into the cooled nutrient solution. Then, the inoculated nutrient solution was placed in a shaker incubator for static culture for 3 days.

[0038] 4. Take out the cultured composite bacterial cellulose, wash it with deionized water, put it into 0.11mol / L NaOH solution, and boil it in alkali for 12 hours in a water bath at 80°C to remove residual culture medium and bacteria. After the alkali boiling, the bacterial cellulose was rinsed again with deionized water until it became neutral, and then put into 80° C. deioni...

Embodiment 3

[0041] 1. Tryptone, yeast powder and mannitol are configured nutrient solution according to mass ratio 4.5:3:25.5; 2 ) in nano-TiO with a concentration of 1g / L 2 Immerse in the suspension for 30min.

[0042] 2. Pour 180mL of nutrient solution and soaked sample into a 500mL Erlenmeyer flask, seal and sterilize in an autoclave at 126°C and 0.15MP for 1 hour.

[0043] 3. In the biological safety cabinet, use a pipette gun to pipette 10mL of the original bacterial solution into the cooled nutrient solution. Then, the inoculated nutrient solution was placed in a shaker incubator for static culture for 5 days.

[0044] 4. Take out the cultured composite bacterial cellulose, wash it with deionized water, put it into 0.11mol / L NaOH solution, and boil it in alkali for 8 hours in a water bath at 80°C to remove residual culture medium and bacteria. After the alkali boiling, the bacterial cellulose was rinsed again with deionized water to neutrality, and put into deionized water at 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com