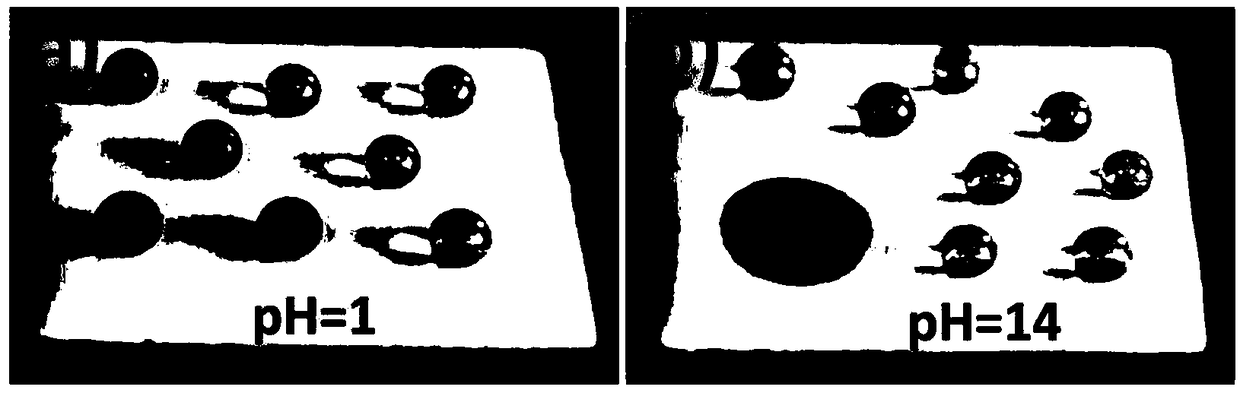

Preparation method and applications of super hydrophobic oleophobic material with pH responsiveness

A super-amphiphobic and responsive technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., to achieve excellent super-hydrophobicity/super-oleophobicity, excellent buoyancy, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

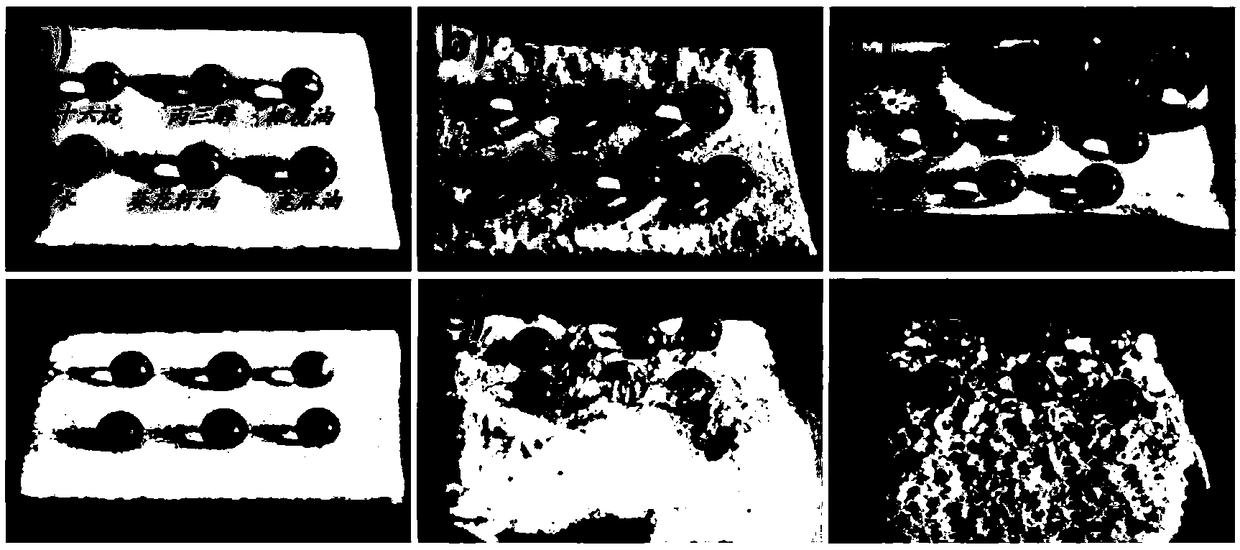

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a pH-responsive super-amphiphobic material, comprising the following steps:

[0035] Step 1. Prepare an ethanol solution of bis[3-(trimethoxysilyl)propyl]ethylenediamine (i.e. 1834 silane) with a volume fraction of 1.8% to 2.5%. Mix 0.2 mL of 1834 silane with a purity of 98% and to its volume ratio (ie V 1834 :V 无水乙醇 ) about 1:49 in absolute ethanol, and then continuously stir the obtained mixed solution for 30 minutes to obtain an ethanol solution of 1834 silane with a volume fraction of about 1.8% to 2.5%, which is set aside.

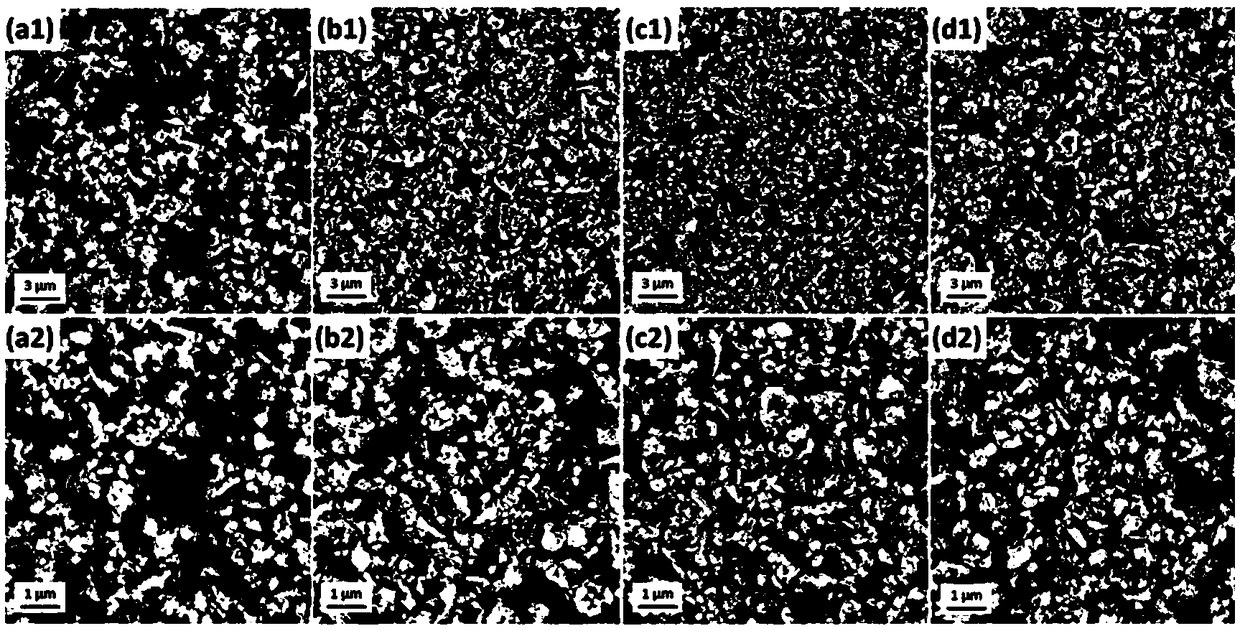

[0036] Step 2. Prepare a pH-responsive superamphiphobic material: Weigh 0.65g of perfluorooctanoic acid (PFOA) with a purity of 98%, add it to 8.5mL of absolute ethanol and magnetically stir until it is completely dissolved, and then add it to the mixed solution Add to PFOA mass ratio (W 高岭土 :W PFOA ) about 6-7.5:1 kaolin particles, ultrasonically oscillate for 30 minutes to disperse the kaolin evenly in the solution...

Embodiment 2

[0051] Add kaolin with a particle size of 300-400nm to the ethanol solution of perfluorooctanoic acid, mix well, add the ethanol solution of silane, heat to 50°C with stirring, and keep it warm for 4 hours to obtain a suspension, and coat the suspension on the substrate surface, and dried to obtain a pH-responsive superamphiphobic material.

[0052] Wherein, the silane is bis[3-(trimethoxysilyl)propyl]ethylenediamine, and the ratio of perfluorooctanoic acid to ethanol in the ethanol solution of perfluorooctanoic acid is 0.60 g:8.5 mL. The volume concentration of the ethanol solution of silane was 1.8%. The ratio of perfluorooctanoic acid, kaolin and silane ethanol solution is 0.60g: 4.5g: 2.5mL.

Embodiment 3

[0054] Add kaolin with a particle size of 300-400nm to the ethanol solution of perfluorooctanoic acid, mix evenly, add the ethanol solution of silane, heat to 60°C under stirring, and keep it warm for 2 hours to obtain a suspension, and coat the suspension on the substrate surface, and dried to obtain a pH-responsive superamphiphobic material.

[0055] Wherein, the silane is bis[3-(trimethoxysilyl)propyl]ethylenediamine, and the ratio of perfluorooctanoic acid to ethanol in the ethanol solution of perfluorooctanoic acid is 0.70 g:8.5 mL. The volume concentration of the ethanol solution of silane was 2.5%. The ratio of perfluorooctanoic acid, kaolin and silane ethanol solution is 0.70g:4.5g:2.7mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com