Cultivation method for improving quality of Rosa roxburghii Tratt

A cultivation method and a technique for thorn pears are applied in the cultivation field of improving the quality of thorn pears, and can solve the problems of low quality of thorn pears, low success rate of thorn pear seedling raising, unsatisfactory nutrient components, etc. The effect of improving colonization survival rate and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

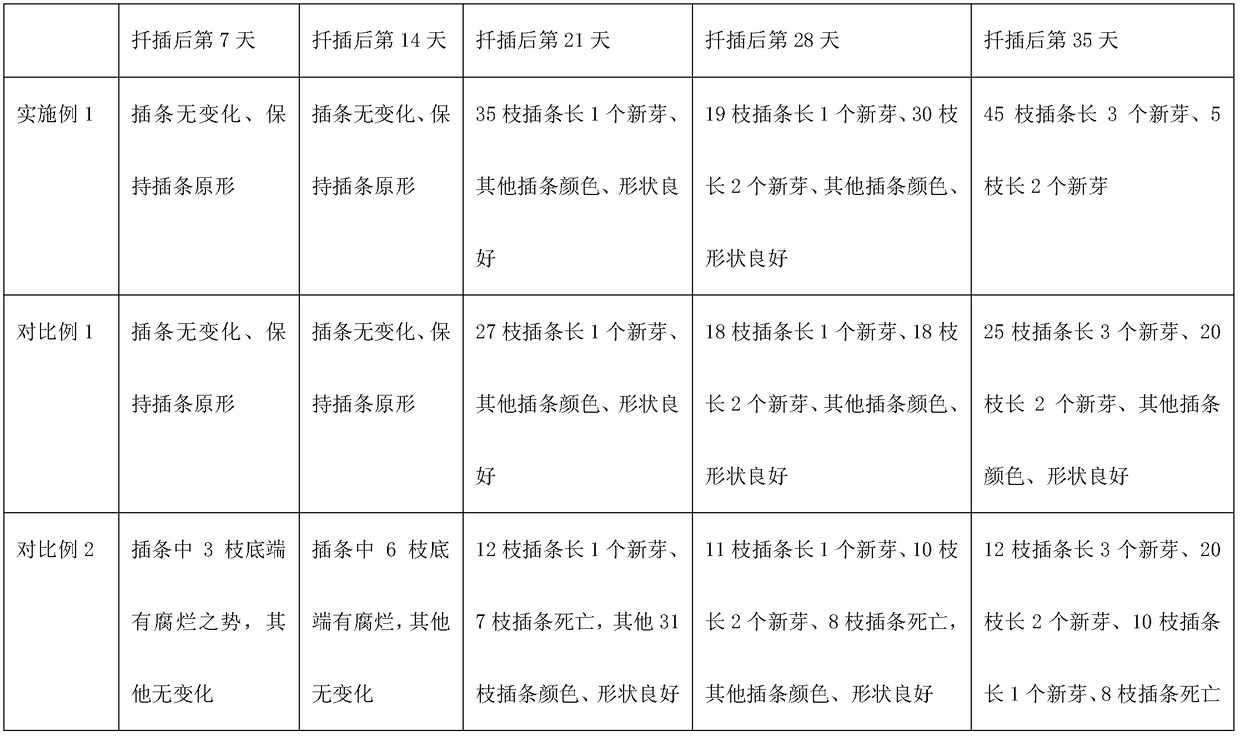

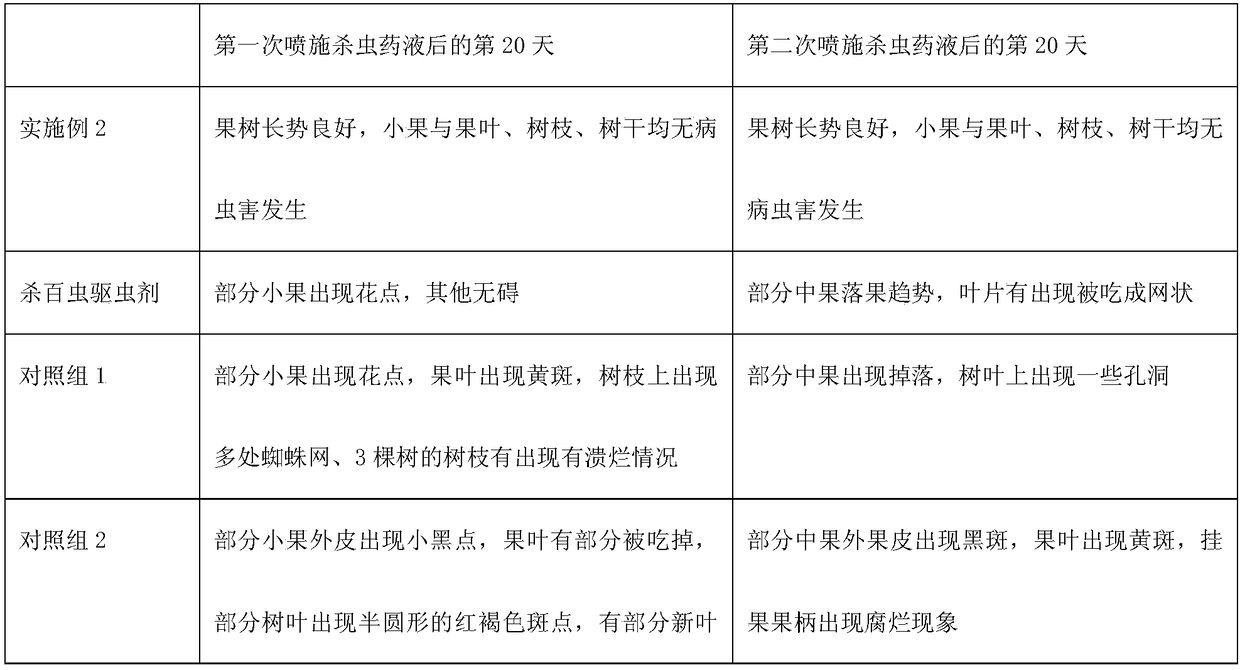

Embodiment 1

[0038] 1. The preparation of bio-organic fertilizer is based on parts by weight. Take 15 parts of chicken manure to build a pile, dig a groove in the center to form a hollow cone, and then sprinkle 3 parts of Gynostemma pentaphyllum extract in the groove and the cone After being exposed to high temperature for 1 day, turn to high-temperature steam to heat for 30 minutes, then cool naturally to room temperature, and then dry and pulverize; take 10 parts of sorghum stalks and put them into kiln dwellings for kiln burning, and burn the stalks into carbon ash. It can be stopped; take 18 parts of oyster shells and grind them, add them to the calciner and calcinate at 800°C for 10 minutes; take 10 parts of phosphorous tailings and grind them quickly to generate heat, and then immediately add hydrogen ions with a content of 6×10 -4 mol / L hydrochloric acid solution, heated to 28°C for 1 hour reaction, then ammoniated, then poured all the material liquid into a porcelain plate, sent it ...

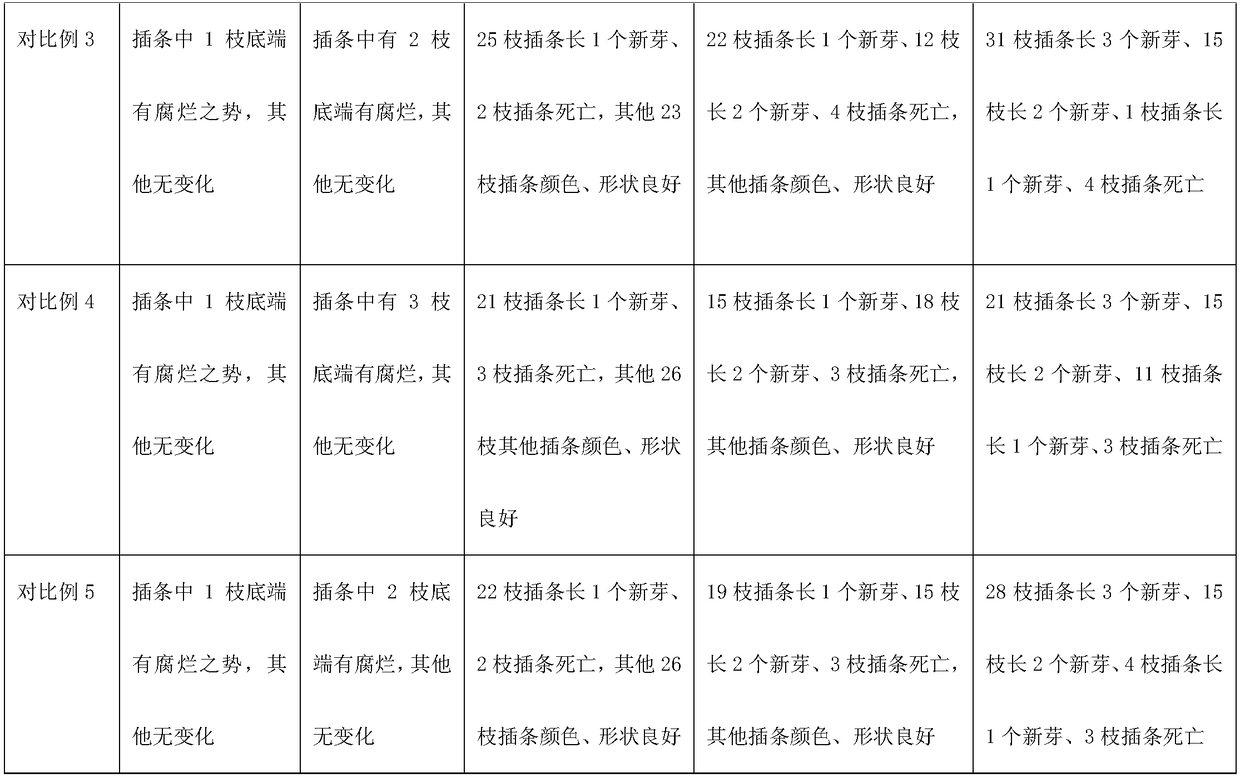

Embodiment 2

[0064] 1. The preparation of bio-organic fertilizer is based on parts by weight. Take 17 parts of chicken manure to build a pile, dig out a groove in the center to form a hollow cone, and then sprinkle 4 parts of Gynostemma pentaphyllum extract in the groove and the cone After 1.5 days of high-temperature exposure, turn to high-temperature steam to heat for 40 minutes, then naturally cool to room temperature, and then dry and pulverize; take 14 parts of sorghum stalks and put them into kiln dwellings for kiln burning, and burn the stalks into carbon ash. It can be stopped; take 22 parts of oyster shells and grind them, add them to the calciner and calcinate at 850°C for 15 minutes; take 15 parts of phosphorus tailings and grind them quickly to generate heat, and then immediately add hydrogen ions with a content of 7×10 -4 mol / L hydrochloric acid solution, heated to 28.5°C for 1.2 hours, then ammonified, then poured all the material liquid into a porcelain plate, sent it to an e...

Embodiment 3

[0090] 1. The preparation of bio-organic fertilizer is based on parts by weight. Take 20 parts of chicken manure to build a pile, dig out a groove in the center to form a hollow cone, and then sprinkle 5 parts of Gynostemma pentaphyllum extract in the groove and the cone After 2 days of high-temperature exposure, turn to high-temperature steam to heat for 50 minutes, then naturally cool to room temperature, and then dry and pulverize; take 18 parts of sorghum stalks and put them into kiln dwellings for kiln burning, and burn the stalks into carbon ash. It can be stopped; take 25 parts of oyster shells for crushing, put them into a calciner and calcinate at 900°C for 20 minutes; take 20 parts of phosphorous tailings and grind them quickly to generate heat, and then immediately add hydrogen ion content of 8×10 -4 mol / L hydrochloric acid solution, heated to 29°C for 1.5 hours, and then carried out ammoniation treatment, then poured all the material liquid into a porcelain plate, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com