Lubricating oil additive and preparation method thereof

A lubricating oil additive and mixed liquid technology, which is applied in the field of lubricating oil, can solve the problems of poor lubricating effect of lubricating oil, environmental and human health hazards, etc., and achieve the effect of increasing lubricating effect, no harm to the environment and human health, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

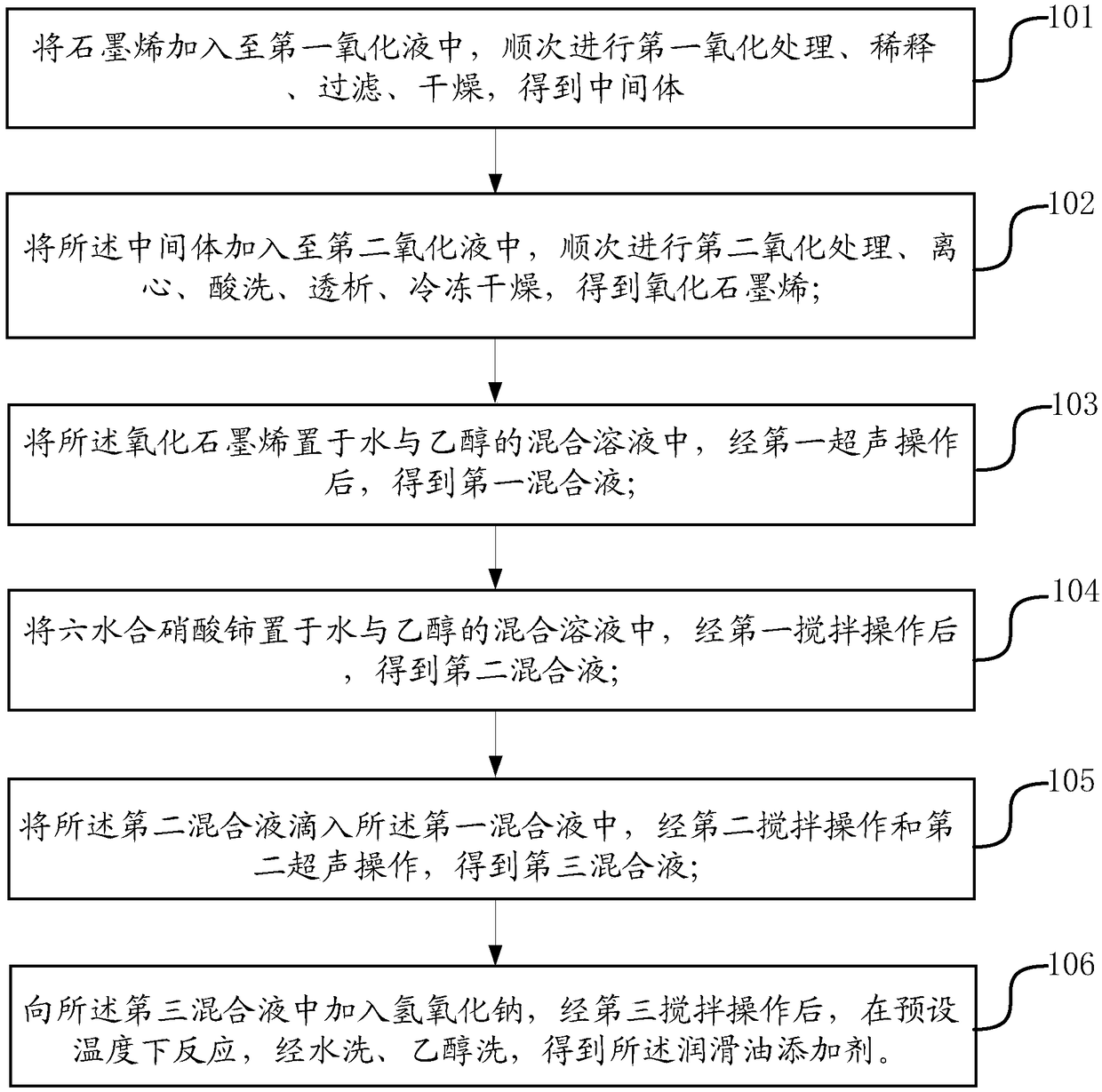

[0035] On the one hand, the embodiment of the present invention provides a kind of preparation method of lubricating oil additive, as attached figure 1 Shown, this preparation method comprises:

[0036] Step 101, adding graphene into the first oxidation solution, performing the first oxidation treatment, dilution, filtration, and drying in sequence to obtain an intermediate.

[0037] Step 102, adding the intermediate to the second oxidation solution, performing the second oxidation treatment, centrifugation, pickling, dialysis, and freeze-drying in sequence to obtain graphene oxide.

[0038] Step 103, placing the graphene oxide in the mixed solution of water and ethanol, and obtaining the first mixed solution after the first ultrasonic operation.

[0039] Step 104, placing cerium nitrate hexahydrate in the mixed solution of water and ethanol, and after the first stirring operation, a second mixed solution is obtained.

[0040] Step 105, drop the second mixed liquid into the ...

Embodiment 1

[0082] This implementation provides a kind of lubricating oil additive, and it is prepared by the following method:

[0083] Add 3g of graphene to 12.5mL of concentrated sulfuric acid, 2.5mL of potassium peroxodisulfate, phosphorus pentoxide, water mixed solution, magnetically stir the reaction for 6h in a water bath at 80°C, then add 500mL of water to the mixed solution to dilute , filtered, and finally dried at 40°C to obtain an intermediate.

[0084] Add the intermediate to 115mL of concentrated sulfuric acid, stir evenly in a water bath at 0°C, then control the temperature of the water bath to 10°C, and slowly add 15g of potassium permanganate, react for 2 hours at 35°C, and then add 230mL of water , and reacted at 45°C for 2h. Finally, 700mL of water and 12.5mL of hydrogen peroxide were added and allowed to stand for a day. The mixture was centrifuged, washed with hydrochloric acid with a mass fraction of 10%, and finally loaded into a dialysis membrane, soaked in water...

Embodiment 2

[0087] This implementation provides a kind of lubricating oil additive, and it is prepared by the following method:

[0088] Add 3g of graphene to 10mL of concentrated sulfuric acid, 2.5mL of potassium peroxodisulfate, phosphorus pentoxide, and water, and stir the reaction for 5.8h under the condition of 78°C in a water bath, then add 500mL of water to the mixture to dilute , filtered, and finally dried at 40°C to obtain an intermediate.

[0089] Add the intermediate to 110mL of concentrated sulfuric acid, stir evenly in a water bath at 0°C, then control the temperature of the water bath at 10°C, and slowly add 13g of potassium permanganate, react at 33°C for 1.8h, and then add 220mL water, reacted at 43°C for 1.8h. Finally, 690mL of water and 12mL of hydrogen peroxide were added and allowed to stand for a day. The mixture was centrifuged, washed with hydrochloric acid with a mass fraction of 10%, and finally loaded into a dialysis membrane, soaked in water for one week, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com