Graphite purifying device and method

A graphite purification and graphite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low temperature, low energy consumption, insufficient energy saving, environmental pollution, etc., and achieve considerable market application prospects, increase Energy consumption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

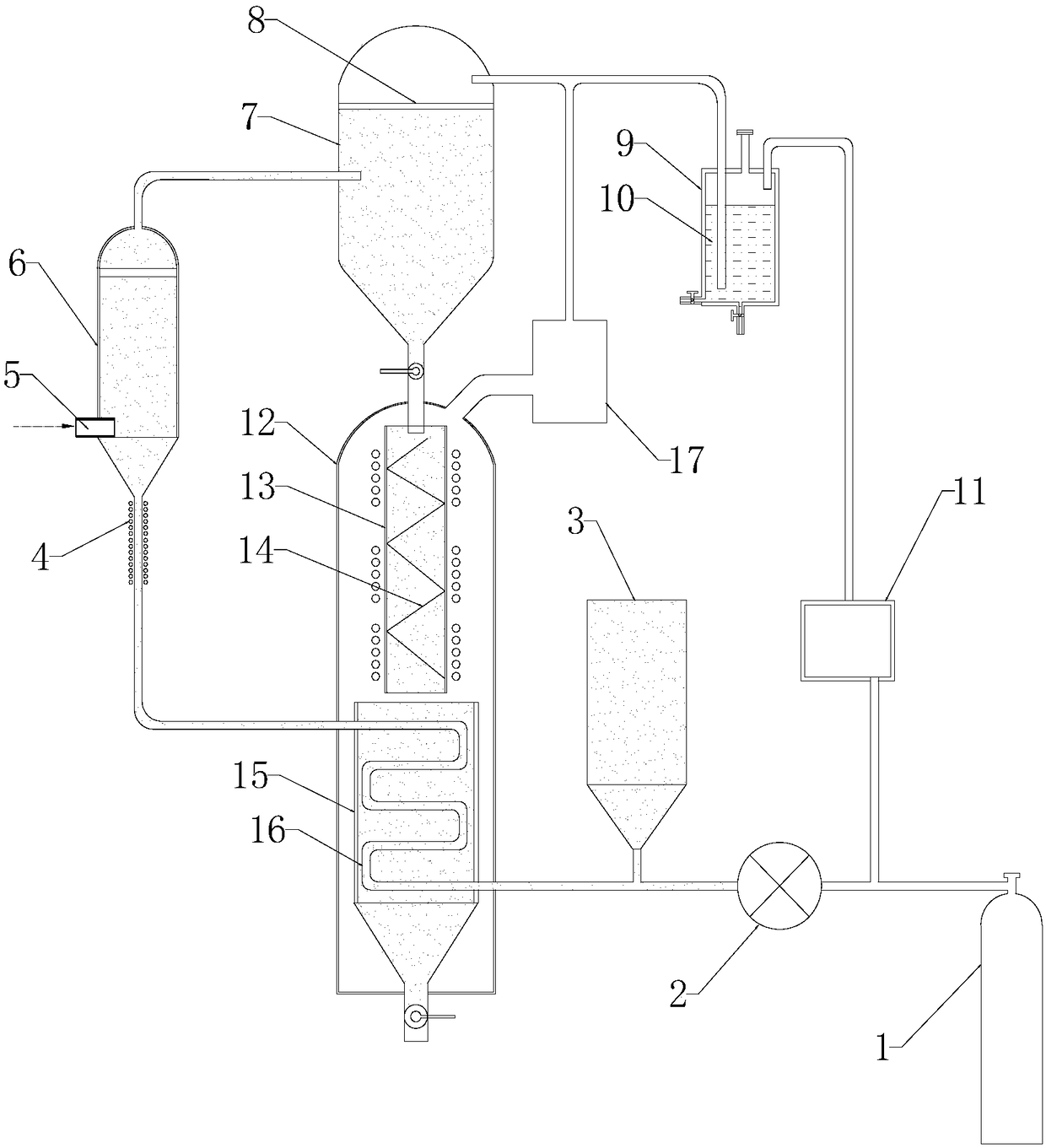

[0064] In this embodiment, a low-temperature reactive ion gas generator 5 is installed at the bottom of the existing fluidized bed reactor 6, and a main frequency induction heating coil is installed at the entrance below the fluidized bed reactor 6 as a preheating device; Then a gas-solid separator 7 is installed at the outlet of the fluidized bed reactor 6, and a waste gas recoverer 9 is installed at the same time, which constitutes a graphite purification device.

[0065] Graphite purification is carried out by using the above-mentioned graphite purification device. First, high-purity Ar gas is used as the transport gas of graphite, and HCl gas is introduced through the low-temperature reactive ion gas generator 5, and HCl gas is ionized and reacts with impurity oxides in graphite, and some of them generate low-boiling-point compounds, and the other part will generate chlorides with relatively high boiling points. The waste gas separated by the gas-solid separator 7 directl...

Embodiment 2

[0067] In this embodiment, the existing small-scale high-frequency induction melting furnace is modified, and a graphite crucible is used as the gas-solid separator 7 that can be heated at high temperature, and two gas pipelines, one in and one out, are designed on the graphite cover. A porous baffle is designed below as a filter baffle 8, the graphite crucible inlet pipe is directly inserted into the bottom of the crucible, and the inlet of the inlet pipe is connected to the fluidized bed reactor 6 with a built-in low-temperature reactive ion gas generator 5, The graphite crucible outlet pipe is connected to the waste gas recovery device 9

[0068] The graphite purification device modified above is used for graphite purification. First, at the beginning of the experiment, the transfer gas Ar was first introduced, and then the induction heating was turned on to raise the temperature of the crucible to 1600 ° C. After 30 minutes, the heating was stopped. After cooling, a sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com