Preparation method of degradation acidity-adjustable self-enhanced polyester/ordered mesoporous degradable bone repair material as well as product and application thereof

A mesoporous material and adjustable technology, applied in the field of biomedical composite materials, can solve the problems of acidity and poor mechanical properties of degradation products, and achieve the effects of overcoming molecular weight loss, improving mechanical properties, and easy processing and molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

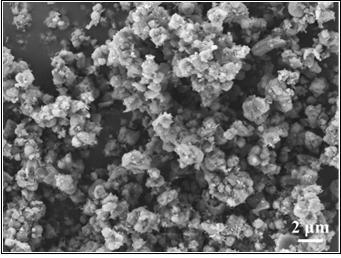

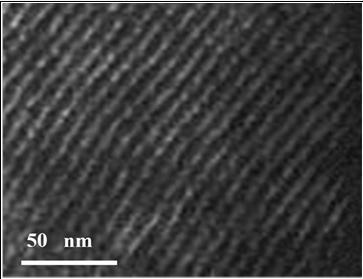

Embodiment 1

[0035] First, the MCM-41 mesoporous material was evacuated and dried at 120 °C for 24 hours to remove the moisture adsorbed in the mesoporous channels. Weigh 1 g of dried MCM-41 and add it to 35 mL of DMF, put it into a three-necked flask that removes water and oxygen, add 1 g of 3-aminopropyltriethoxysilane (APTES) under nitrogen protection and magnetic stirring ), reflux reaction at 80 °C for 12 hours, the product was filtered, washed with a large amount of ethanol and dried to obtain amino-modified MCM-41, denoted as H 2 N-MCM-41. 5 g of lactide was dissolved in 120 ℃, 20 mL of toluene solvent with dehydration and oxygen removal, and the dried 1 g of NH 2 -MCM-41 and 0.0016 mL Sn(Oct) 2 Add it into a single-necked flask, heat it to 90 °C in 20 mL of toluene solvent that removes water and oxygen, and stir evenly, then add it dropwise to the lactide solution under nitrogen protection and magnetic stirring, and react at 120 °C 24 hours. When the above reaction mixture was c...

Embodiment 2

[0044] First, the MCM-41 mesoporous material was evacuated and dried at 120 °C for 24 hours to remove the moisture adsorbed in the mesoporous channels. Weigh 1 g of dried MCM-41 and add it to 35 mL of DMF, put it into a three-necked flask that removes water and oxygen, add 1 g of 3-aminopropyltriethoxysilane (APTES) under nitrogen protection and magnetic stirring ), reflux reaction at 80 °C for 12 hours, the product was filtered, washed with a large amount of ethanol and dried to obtain amino-modified MCM-41, denoted as H 2 N-MCM-41. 5 g of lactide was dissolved in 120 ℃, 20 mL of toluene solvent with dehydration and oxygen removal, and the dried 1 g of NH 2 -MCM-41 and 0.0016 mL Sn(Oct) 2 Add it into a single-necked flask, heat it to 90 °C in 20 mL of toluene solvent that removes water and oxygen, and stir evenly, then add it dropwise to the lactide solution under nitrogen protection and magnetic stirring, and react at 120 °C 24 hours. When the above reaction mixture was c...

Embodiment 3

[0047] First, the MCM-41 mesoporous material was evacuated and dried at 120 °C for 24 hours to remove the moisture adsorbed in the mesoporous channels. Weigh 1 g of dried MCM-41 and add it to 35 mL of DMF, put it into a three-necked flask that removes water and oxygen, add 1 g of 3-aminopropyltriethoxysilane (APTES) under nitrogen protection and magnetic stirring ), reflux reaction at 80 °C for 12 hours, the product was filtered, washed with a large amount of ethanol and dried to obtain amino-modified MCM-41, denoted as H 2 N-MCM-41. 5 g of lactide was dissolved in 120 ℃, 20 mL of toluene solvent with dehydration and oxygen removal, and the dried 1 g of NH 2 -MCM-41 and 0.0016 mL Sn(Oct) 2 Add it into a single-necked flask, heat it to 90 °C in 20 mL of toluene solvent that removes water and oxygen, and stir evenly, then add it dropwise to the lactide solution under nitrogen protection and magnetic stirring, and react at 120 °C 24 hours. When the above reaction mixture was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com