Method for preparing rapid high oil absorption resin by using macromolecule pore-foaming agent

A technology of oleoresin and porogen, which is applied in the field of functional polymer materials, can solve the problems of cost reduction, slow oil absorption rate, and performance degradation, and achieve the effects of cost reduction, performance degradation, and high oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 3.129 grams of poly-n-butyl methacrylate in 3.129 grams of n-butyl methacrylate, then add 1.252 grams of Span 80 and 0.275 grams of divinylbenzene into n-butyl methacrylate, stir evenly, and pass Nitrogen for 40 minutes to obtain an oily phase. Take 32 grams of deionized water as the water phase, and add the water phase to the oil phase dropwise at a constant speed at a stirring speed of 1000 rpm. After the dropwise addition, 0.082 g of ammonium persulfate (0.36 mmol) and 0.037 g of sodium bisulfite (0.356 mmol) were weighed to prepare an aqueous solution, added to the above emulsion, and continued to stir for 20 minutes until the emulsion was stable. React at 40 degrees Celsius for 24 hours, extract the product through a Soxhlet extractor for more than 12 hours, and dry it in vacuum to obtain a fast high oil-absorbing resin.

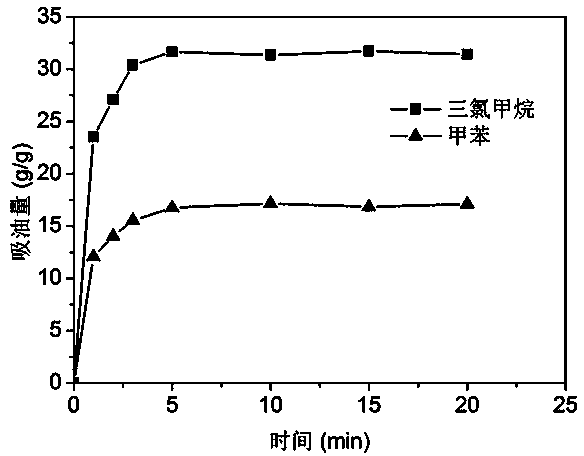

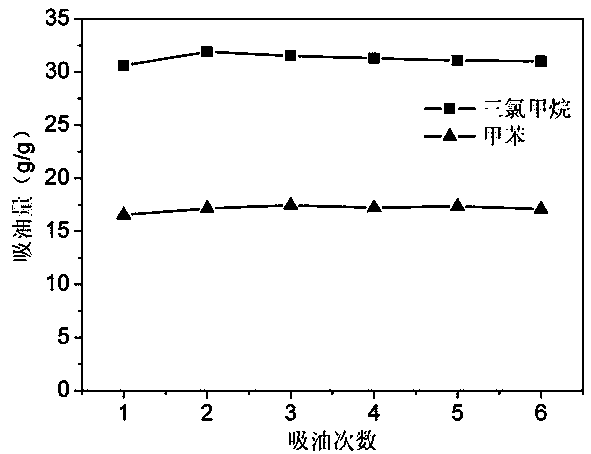

[0026] The obtained rapid high oil-absorbing resin has an oil absorption rate of 31 times for chloroform and 17 times for toluene; the...

Embodiment 2

[0031] Dissolve 1.877 g of polymethyl methacrylate in 4.381 g of methyl methacrylate, then add 1.252 g of Span 80 and 0.386 g of divinylbenzene into the methyl methacrylate, stir evenly, and blow in nitrogen for 20 minutes , to obtain the oil phase. Take 50 grams of deionized water as the water phase, and add the water phase to the oil phase dropwise at a constant speed at a stirring speed of 1000 rpm to obtain an emulsion. After the dropwise addition, weigh 0.114 g of ammonium persulfate (0.5 mmol) and 0.052 g of sodium bisulfite (0.5 mmol) to prepare an aqueous solution, add it to the above emulsion, and continue to stir for 30 minutes until the emulsion is stable. React at 50 degrees Celsius for 24 hours, extract the product through a Soxhlet extractor for more than 12 hours, and dry it in vacuum to obtain a fast high oil-absorbing resin.

[0032] The obtained rapid high oil-absorbing resin has an oil absorption rate of 17 times for chloroform and 9 times for toluene; the ...

Embodiment 3

[0034] Dissolve 2.503 g of n-butyl polyacrylate in 3.755 g of n-butyl acrylate, then add 1.252 g of Span 60 and 0.25 g of divinylbenzene into n-butyl acrylate, stir evenly, and inject nitrogen gas for 20 minutes to obtain oil Mutually. Take 32 grams of deionized water as the water phase, and add the water phase to the oil phase dropwise at a constant speed at a stirring speed of 1100 rpm to obtain an emulsion. After the dropwise addition, weigh 0.079 g of ammonium persulfate (0.346 mmol) and 0.035 g of sodium bisulfite (0.337 mmol) to prepare an aqueous solution, add it to the above emulsion, and continue stirring for 20 minutes until the emulsion is stable. React at 40 degrees Celsius for 24 hours, extract the product through a Soxhlet extractor for more than 12 hours, and dry it in vacuum to obtain a fast high oil-absorbing resin.

[0035] The obtained rapid high oil-absorbing resin has an oil absorption rate of 22 times for chloroform and 11 times for toluene; the time req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com