High wear-resistant sand mist-containing sealing layer material and its preparation method and application

A fog sealing material and aggregate technology, applied in the direction of coating, can solve the problems of poor wear resistance, difficult to meet the requirements of the open traffic time limit of municipal roads, etc., achieve fast curing time, suitable for industrial scale production, The effect of short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

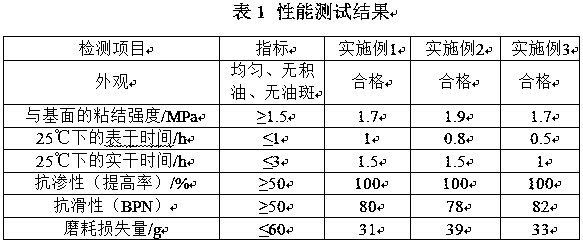

Examples

Embodiment 1

[0059] The sand mist-containing sealing layer material is prepared from the following raw materials according to the following steps:

[0060] A. Raw material preparation

[0061] A1. Preparation of modified MMA resin: 60 parts of MMA (methyl methacrylate) monomer, 20 parts of vinyl acetate monomer, 20 parts of n-butyl acrylate monomer, 0.3% azobisisobutyronitrile, 0.5% of dioctyl phthalate and 0.4% of 2-hydroxy-4-n-octyloxybenzophenone were mixed and stirred evenly at 65°C, and reacted for 1h to obtain a modified MMA resin; wherein, the The percentages of azobisisobutyronitrile, dioctyl phthalate, and 2-hydroxy-4-n-octyloxybenzophenone are methyl methacrylate monomer, vinyl acetate monomer and acrylic n- The percentage of the total mass of butyl ester monomer;

[0062] A2. Weighing

[0063] Curing agent: take 2% dibenzoyl peroxide (BPO) of the quality of the modified MMA resin prepared in step A1 as the curing agent;

[0064] Matting agent: take by weighing 0.5% of the si...

Embodiment 2

[0070] The sand mist-containing sealing layer material is prepared from the following raw materials according to the following steps:

[0071] A. Raw material preparation

[0072] A1. Preparation of modified MMA resin: 60 parts of MMA (methyl methacrylate) monomer, 40 parts of comonomer vinyl acetate, 40 parts of comonomer isobutyl acrylate, 0.5% of azobisisobutyl Nitrile, 1% polybutylene terephthalate, and 1% 2,4,6-tri-tert-butylphenol were mixed and stirred evenly at 65°C, and reacted for 1h to obtain a modified MMA resin; wherein, the The percentages of azobisisobutyronitrile, polybutylene terephthalate and 2,4,6-tri-tert-butylphenol are methyl methacrylate monomer, vinyl acetate monomer and isobutyl acrylate The percentage of the total mass of ester monomers;

[0073] A2. Weighing

[0074] Curing agent: take 3% dibenzoyl peroxide (BPO) of the quality of the modified MMA resin prepared in step A1 as the curing agent;

[0075] Matting agent: take by weighing 0.5% titaniu...

Embodiment 3

[0081] The sand mist-containing sealing layer material is prepared from the following raw materials according to the following steps:

[0082] A. Raw material preparation

[0083] A1. Preparation of modified MMA resin: 100 parts of MMA (methyl methacrylate) monomer, 20 parts of comonomer vinyl acetate monomer, 20 parts of comonomer neobutyl acrylate monomer, 0.3% of Azodiisobutyronitrile, 0.8% polypropylene glycol diglycidyl ether and 0.8% p-tert-butylphenol were mixed and stirred evenly at 65°C, and reacted for 2 hours to obtain a modified MMA resin; wherein, the azobisiso The percentages of nitrile, polypropylene glycol diglycidyl ether and p-tert-butylphenol are the percentages of the total mass of methyl methacrylate monomer, vinyl acetate monomer and neobutyl acrylate monomer;

[0084] A2. Weighing

[0085] Curing agent: the modified MMA resin prepared according to step A1: the mass ratio of dibenzoyl peroxide (BPO) is 60:4, and dibenzoyl peroxide (BPO) is weighed as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impermeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com