Formula of nano silicon carbide powder coating and preparation method thereof

A nano-silicon carbide and powder coating technology, applied in powder coatings, fireproof coatings, asphalt coatings, etc., can solve the problems of stain resistance, salt spray resistance, aging resistance, abrasion resistance, scratch resistance, adhesion and cold resistance Poor thermal shock energy, no anti-virus, mildew-proof, no impact resistance, etc., to achieve good adhesion, good resistance to cold and heat shocks, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

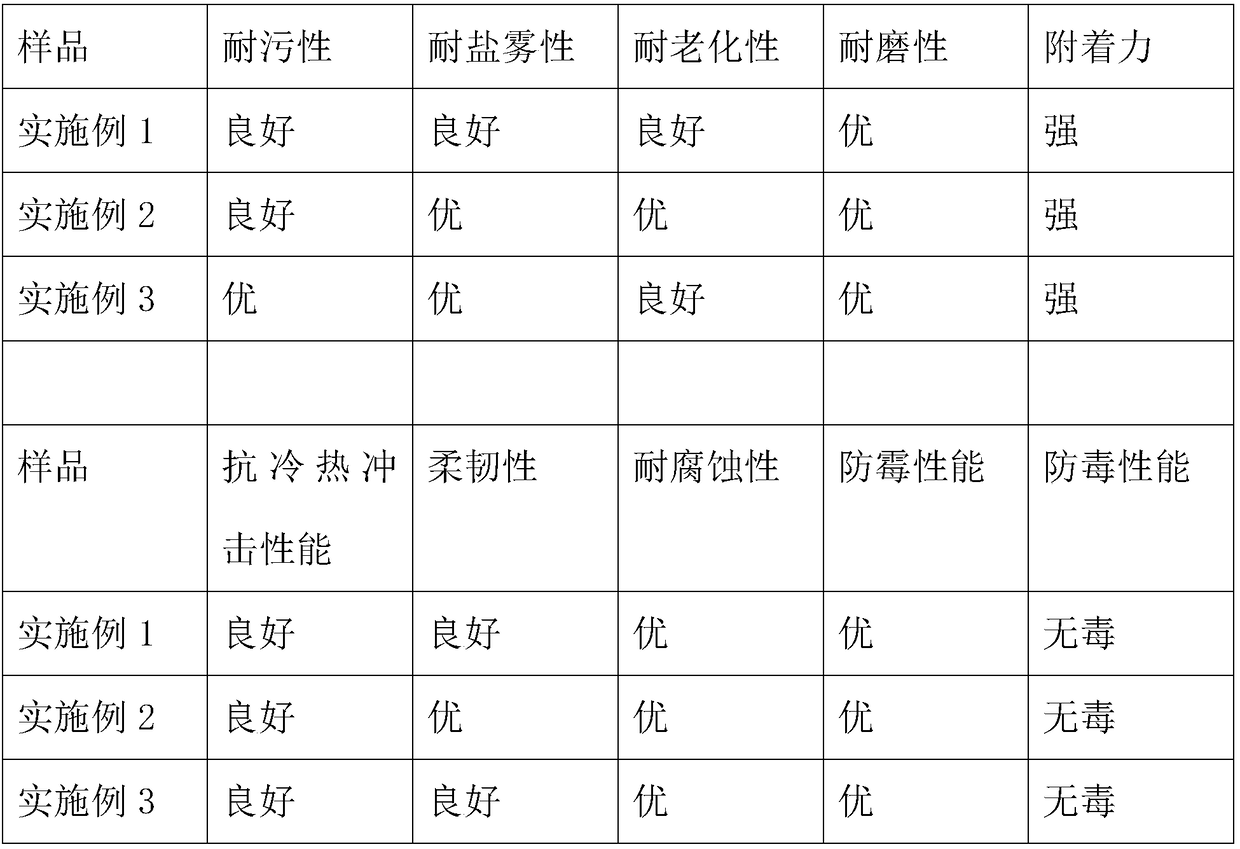

Examples

preparation example Construction

[0022] A preparation method of nano-silicon carbide powder coating, comprising the following steps:

[0023] Step 1: Batching: Use an electronic scale to weigh each formula ingredient on component A, component B and component C to obtain the corresponding measurement;

[0024] Step 2: Grinding: put component A, component B and component C into the grinding cylinder for grinding, the grinding time is 30 minutes; the fineness of the grinding particles is 20-25nm, and the grinding speed is 1200 rpm;

[0025] Step 3: Reaction: Put the mixture of component A into the reactor and heat up to 80 degrees Celsius; and stir at a speed of 700r / min for 20 minutes; then put component B into the reactor and heat up the reactor to 130 degrees Celsius, and stirred at a rotating speed of 1300r / min for 30 minutes, then put the third component into the reactor, lowered the reactor to 100 degrees Celsius, and stirred at a rotating speed of 1000r / min for 30 minutes, then cooled for a while Hour; ...

Embodiment 1

[0030] Including components A, B and C, component A includes: acrylic emulsion, nano-silicon carbide powder, styrene-butadiene rubber and modified high-chlorinated polyethylene resin; component B includes: feldspar powder, emery, ceramics Micropowder, mica powder, high temperature resistant pigment, calcium carbonate, talcum powder, barium sulfate, asphalt and white cement; component C includes: dispersant, defoamer, wetting agent, bactericide and antifungal agent, leveling agent, crosslinking agent agent, wetting agent, slipping aid, film-forming aid, thickener and water; component A is 50%; among them, acrylic emulsion is 20%, nano-silicon carbide powder is 15%, and styrene-butadiene rubber is 8%. % and modified high chlorinated polyethylene resin is 1%; component B is 10%; among them, feldspar powder, corundum, ceramic powder, mica powder, high temperature resistant pigment, calcium carbonate, talcum powder, barium sulfate, asphalt and white Cement is 1%; C component is 10%...

Embodiment 2

[0037] Including components A, B and C, component A includes: acrylic emulsion, nano-silicon carbide powder, styrene-butadiene rubber and modified high-chlorinated polyethylene resin; component B includes: feldspar powder, emery, ceramics Micropowder, mica powder, high temperature resistant pigment, calcium carbonate, talcum powder, barium sulfate, asphalt and white cement; component C includes: dispersant, defoamer, wetting agent, bactericide and antifungal agent, leveling agent, crosslinking agent agent, wetting agent, slipping aid, film-forming aid, thickener and water; component A is 60%; among them, acrylic emulsion is 25%, nano-silicon carbide powder is 20%, and styrene-butadiene rubber is 10%. % and modified high chlorinated polyethylene resin is 5%; component B is 15%; among them, feldspar powder, corundum, ceramic powder, mica powder, high temperature resistant pigment, calcium carbonate, talcum powder, barium sulfate, asphalt and white Cement is 1.5%; C component is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com