Chromium-aluminum-zinc red pigment preparation method

A chrome-aluminum and pigment technology, applied in the field of preparation of chrome-aluminum-zinc red pigments, can solve the problems of uneven coloring, long time, expensive equipment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

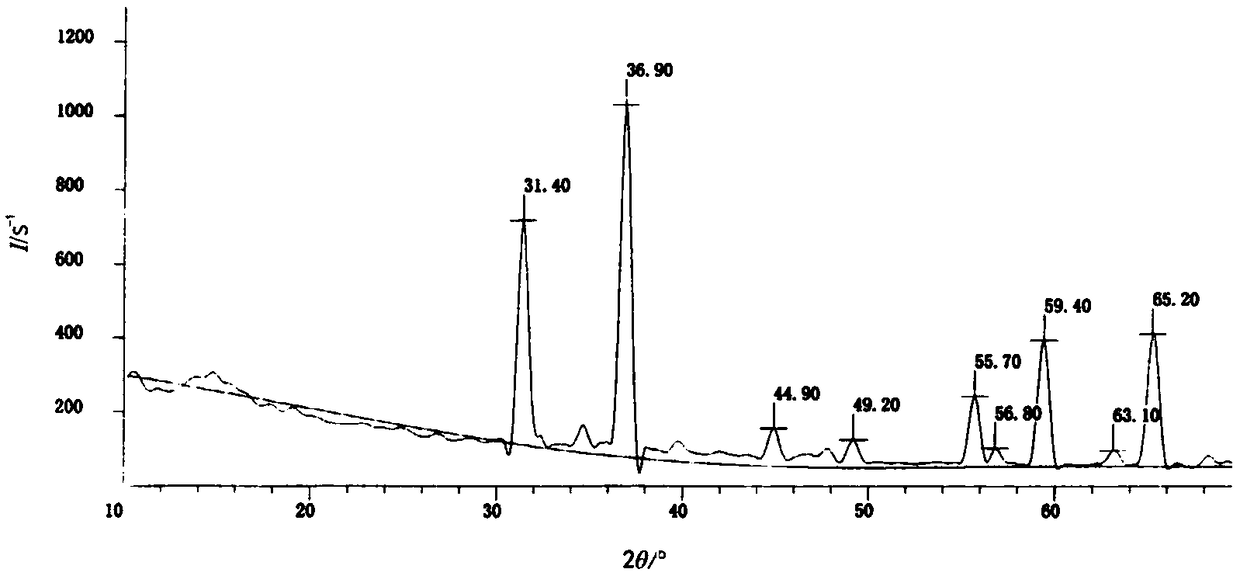

Embodiment 1

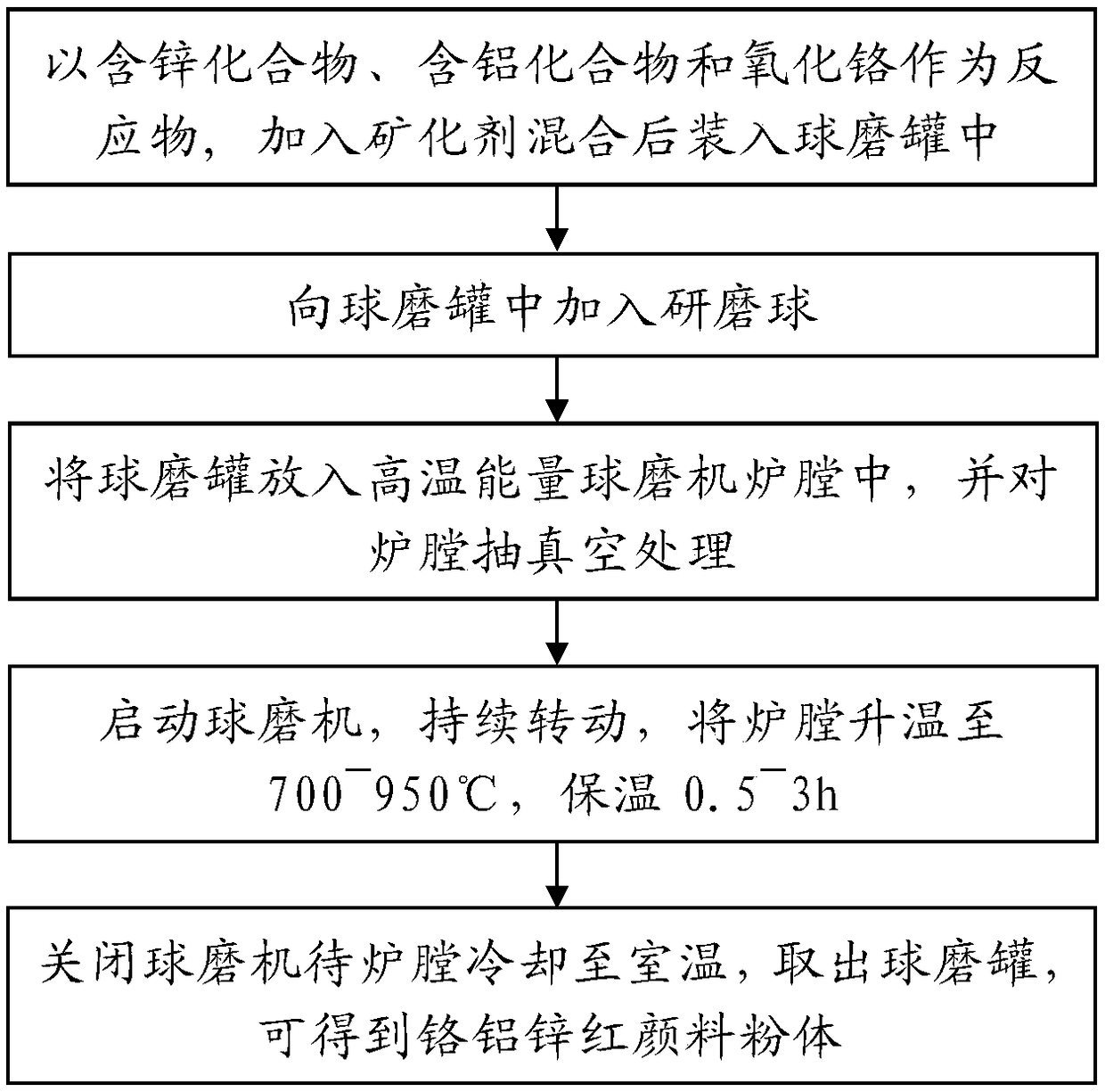

[0033] (1) Zinc oxide, aluminum oxide, and chromium oxide are selected as raw materials, and the molar ratio of zinc element and aluminum element is 1:2. The total mass of zinc source and aluminum source accounts for 95% of the total mass of reactants, and chromium oxide is a coloring agent. The content of chromium oxide accounts for 5% of the total mass of the ingredients, and borax is selected as the mineralizer, and the content of borax is 7% of the mass of the reactant. After being mixed evenly, it is loaded into a ball mill tank.

[0034] (2) Add grinding balls according to the ball-to-material ratio of 30:1, cover the lid, and seal the ball mill jar.

[0035] (3) Put the ball mill jar into the hearth of the high-temperature energy ball mill for vacuuming.

[0036] (4) Start the ball mill, continue to rotate, and at the same time raise the temperature of the furnace to 700°C, and keep it warm for 0.5h.

[0037] (5) Turn off the ball mill and wait for the furnace to cool ...

Embodiment 2

[0039] (1) Zinc oxide, aluminum hydroxide, and chromium oxide are selected as raw materials, and the molar ratio of zinc to aluminum is 1:2. The total mass of zinc source and aluminum source accounts for 85% of the total mass of reactants, and chromium oxide is the colorant , the content of chromium oxide accounts for 15% of batching total mass, selects borax as mineralizer for use, and borax content is 5% of reactant quality, mixes and packs in the ball mill jar.

[0040] (2) Add grinding balls according to the ball-to-material ratio of 30:1, cover the lid, and seal the ball mill jar.

[0041] (3) Put the ball mill jar into the hearth of the high-temperature energy ball mill for vacuuming.

[0042] (4) Start the ball mill, continue to rotate, and at the same time raise the temperature of the furnace to 700°C and keep it warm for 3 hours.

[0043] (5) Turn off the ball mill and wait for the furnace to cool down to room temperature, and take out the ball mill jar to obtain chr...

Embodiment 3

[0045] (1) Zinc hydroxide, aluminum oxide, and chromium oxide are selected as raw materials, and the ingredients are formulated according to the molar ratio of zinc and aluminum elements at 1:2. The total mass of zinc source and aluminum source accounts for 95% of the total mass of the reactants, and chromium oxide is the colorant , the content of chromium oxide accounts for 5% of batching total mass, selects borax as mineralizer for use, and borax content is 8% of reactant quality, mixes and packs in the ball mill jar.

[0046] (2) Add grinding balls according to the ball-to-material ratio of 20:1, cover the lid, and seal the ball mill jar.

[0047] (3) Put the ball mill jar into the hearth of the high-temperature energy ball mill for vacuuming.

[0048] (4) Start the ball mill, continue to rotate, and at the same time raise the temperature of the furnace to 750° C., and keep it warm for 2 hours.

[0049] (5) Turn off the ball mill and wait for the furnace to cool down to ro...

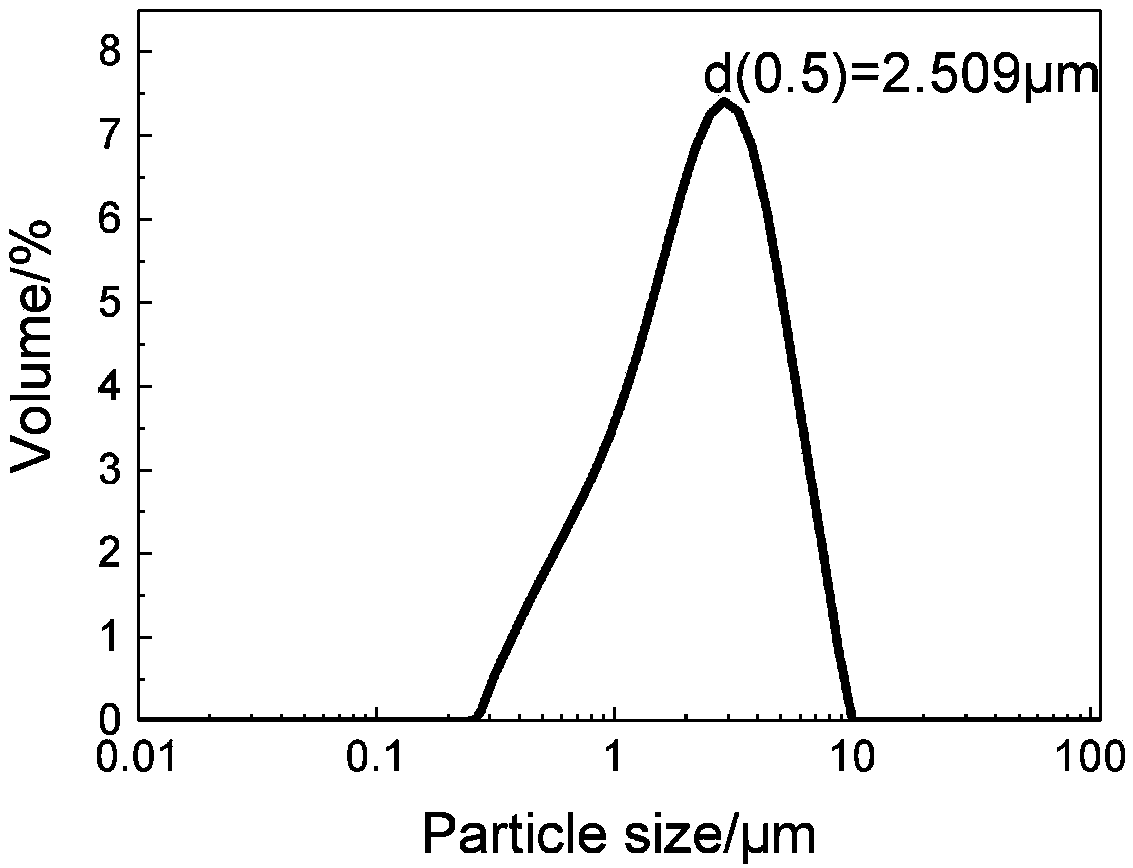

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com