Coating material mixing stirring system with cooling structure

A technology of mixing, stirring and cooling structure, which can be used in mixers, mixer accessories, dissolution and other directions, and can solve problems such as uneven mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

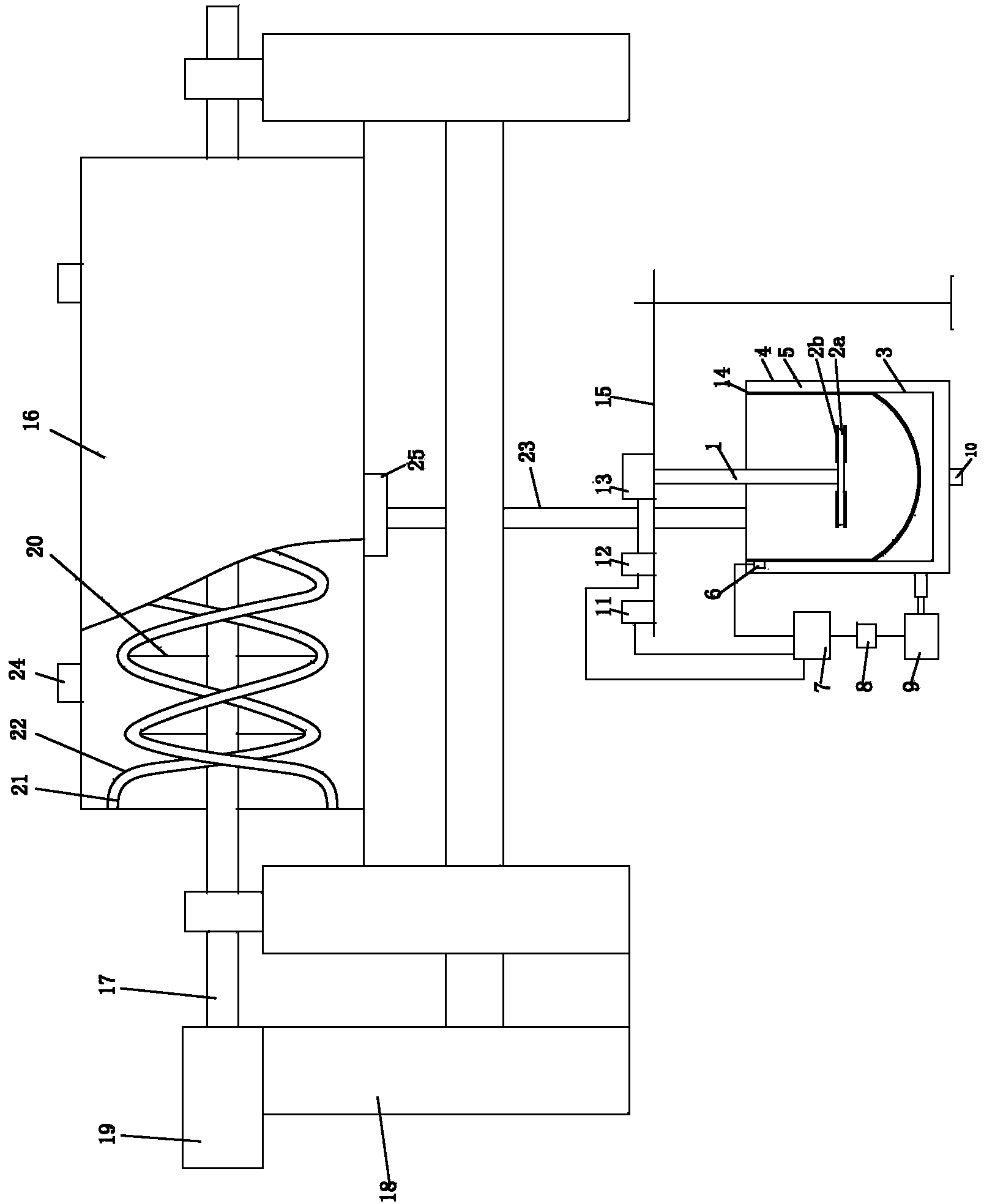

[0012] refer to figure 1 , a paint mixing and stirring system with a cooling structure of the present invention, including a stirring device and a mixing device.

[0013] The stirring device comprises a tank body and a stirring shaft 1 installed in the tank body, and a stirring block is arranged on the stirring shaft. The stirring block includes a fixed block 2a and a sliding block 2b, and the sliding block is slidably fitted on the fixed block and then fastened together with the fixed block by screws. The tank body consists of an inner tank body 3 and an outer tank body 4 surrounding the inner tank body. The inner bottom surface of the inner tank body is a spherical surface, and the inner tank body wall surface of the spherical surface can avoid stirring dead angles during the stirring process. The inner wall surface of the inner tank body 3 is provided with a wear-resistant layer 14, which can increase the wear resistance of the tank body and prolong the service life of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com