Variable-frequency and variable-intensity feed vibration cutting and stirring device and method

A technology for vibrating cutting and stirring devices, applied in chemical instruments and methods, transportation and packaging, shaking/oscillating/vibrating mixers, etc. The effect of reducing viscosity, reducing cutting resistance and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

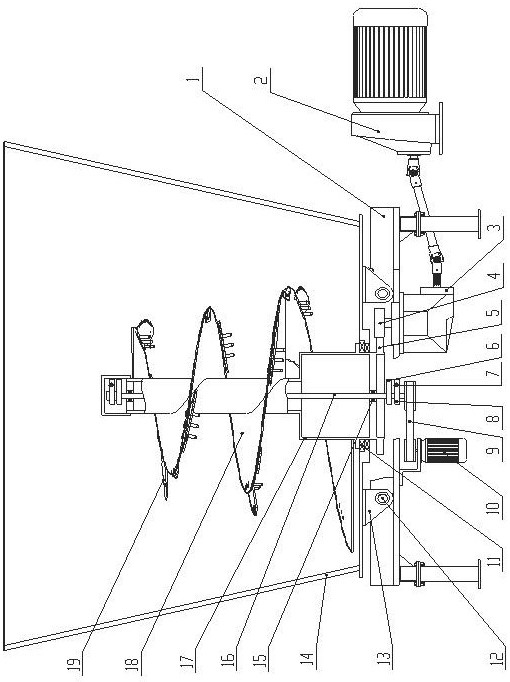

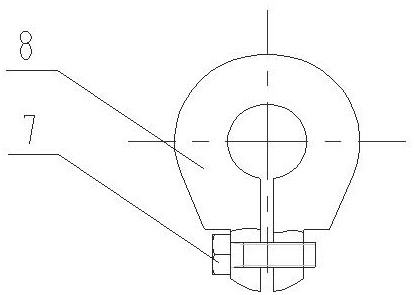

[0026] like figure 1 A feed vibration cutting and stirring device with variable frequency and intensity is shown, including a tank body 14, a cutting and stirring spindle 17 rotatably connected with the tank body, and a first driving device for driving the rotation of the cutting and stirring spindle, the tank body and the cutting and stirring spindle. The axes of the stirring main shafts are all arranged in the vertical direction to form a vertical structure. A bottom frame 1 is arranged below the tank body, the bottom frame 1 is placed horizontally on the ground, a load cell 12 for weighing the weight of the tank body is fixedly arranged on the bottom frame, and a connecting seat 13 is fixed to the bottom of the tank body. 13 is connected to the load cell 12 fixed on the chassis.

[0027] The first driving device includes a prime mover 2, and a reducer 3 that is connected to the prime mover through a universal joint. The reducer 3 is installed on the chassis 1, and the outp...

Embodiment 2

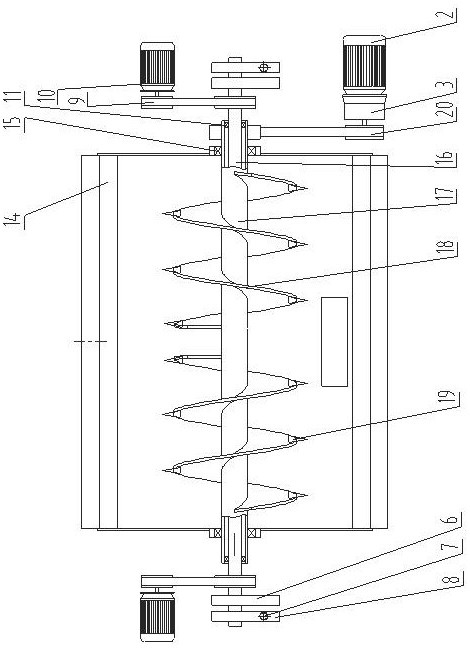

[0038] like image 3 As shown in the figure, the difference between this embodiment and the first embodiment is that the axes of the tank body, the cutting and stirring main shaft and the synchronous transmission shaft in this embodiment are all arranged in the horizontal direction, in a horizontal structure, and the two ends of the cutting and stirring main shaft are respectively horizontal The direction extends out of the tank body, and is respectively connected with the tank body through the bearing group in rotation, so as to improve the balance of the cutting and stirring spindle.

[0039] The prime mover is directly connected to the reducer, the output shaft of the reducer is connected to the cutting and stirring main shaft through the belt II20, and the output shaft of the prime mover and the cutting and stirring main shaft are respectively equipped with pulleys adapted to the belt II20.

[0040] Frequency conversion motors 10 are respectively arranged on the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com