Touch product and production method

A production method and touch technology, which is applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of difficult vibration force, large vibrator size, and large product space, so as to reduce space The effect of occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

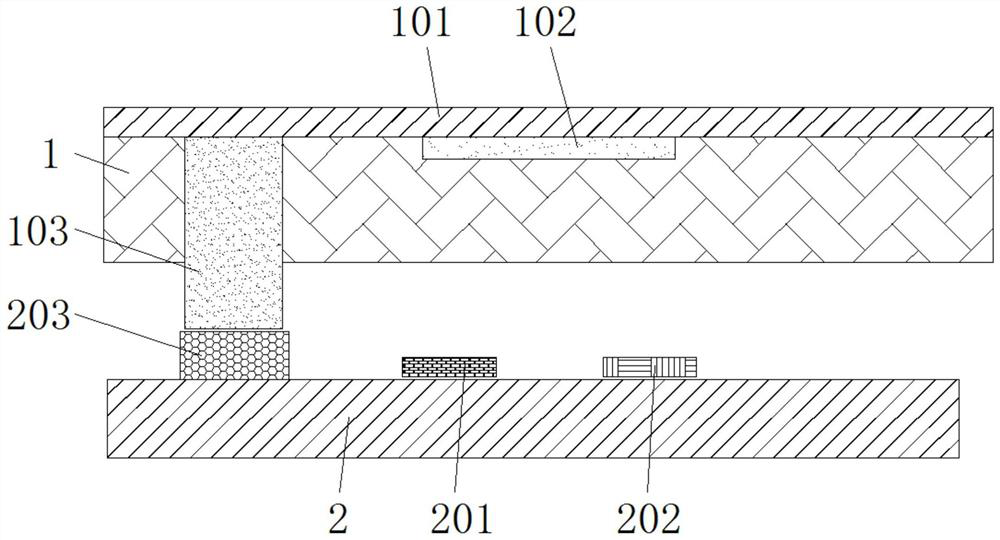

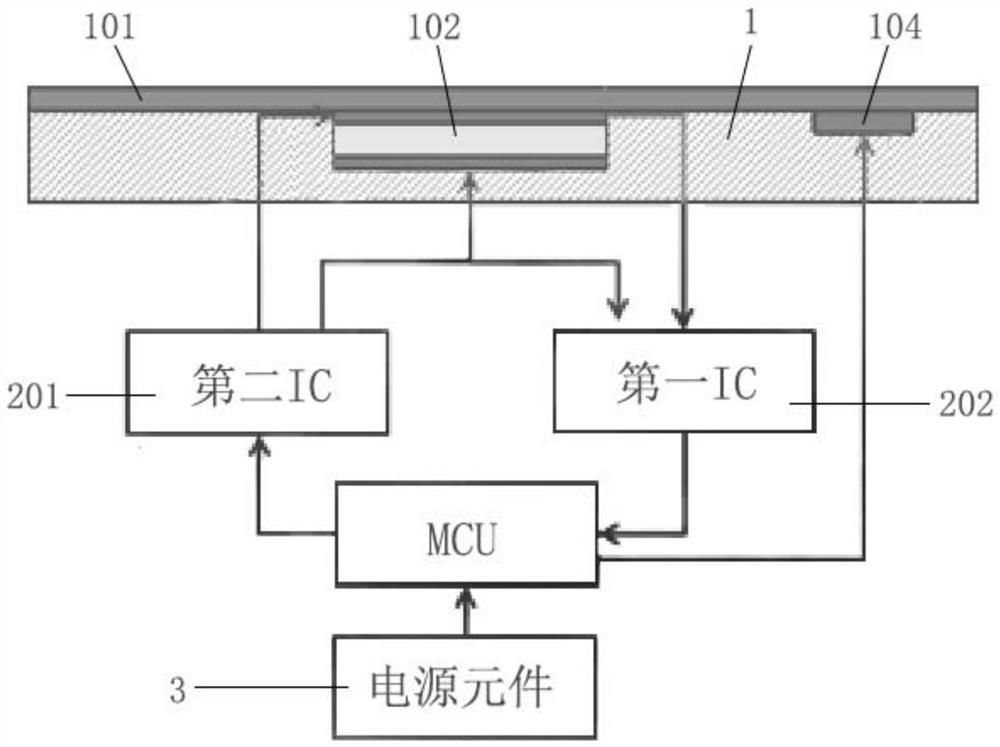

[0040] Such as Figure 1-2 As shown, the embodiment of the present invention provides a touch product, including an insulating case 1 and a PCBA board 2 , and the insulating case 1 is provided with a functional film 102 . In the embodiment of the present invention, the insulating housing 1 may be a plastic housing.

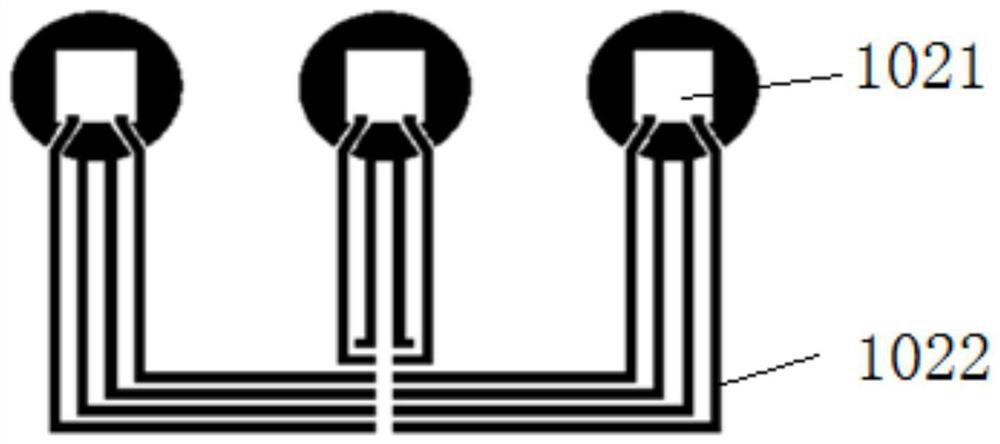

[0041] The functional film 102 is integrated with a touch sensing function and a vibration function. Specifically, the functional film 102 can be integrated with a capacitive sensing element 1021 , a piezoelectric material 1023 and a printed circuit 1022 . The capacitive sensing element 1021 can sense external touch and generate a micro-current signal, which is transmitted to the PCBA board 2 through the printed circuit 1022 to realize the inductive transmission of the touch signal. The PCBA board 2 can output a vibration signal according to the touch signal transmitted by the capacitive sensing element 1021 to control the piezoelectric material 1023 to perform ...

Embodiment 2

[0050] The embodiment of the present invention provides a method for producing a touch product, which can be used to produce the touch product described in Embodiment 1, including the following steps:

[0051] Step 1: Attach the functional film 102 integrated with the indicator light 104, touch sensing function and vibration function to the decorative film 101, and place the functional film and the decorative film in the molding cavity of the injection mold;

[0052] The decorative film can use Film film, and can print decorative patterns, functional symbols, etc. as required;

[0053] Such as Figure 5 As shown, the injection mold includes a mold core A4 and a mold core B5. In the mold closing state, the mold core A4 and the mold core B5 cooperate to form the molding cavity of the insulating housing 1. The functional film 102 and the decorative film 101 can be placed in the mold core A4. In the mold cavity, and place the second connector 103 in the mold core B5;

[0054] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com