A coaxial vibration gear used in the vibrating drug delivery unit of the storage type powder mist drug delivery device

A technology of drug delivery device and powder aerosol, which is applied in the field of coaxial vibration gear used in the vibrating drug delivery unit of storage type powder aerosol drug delivery device, which can solve the problems of poor powder fluidity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

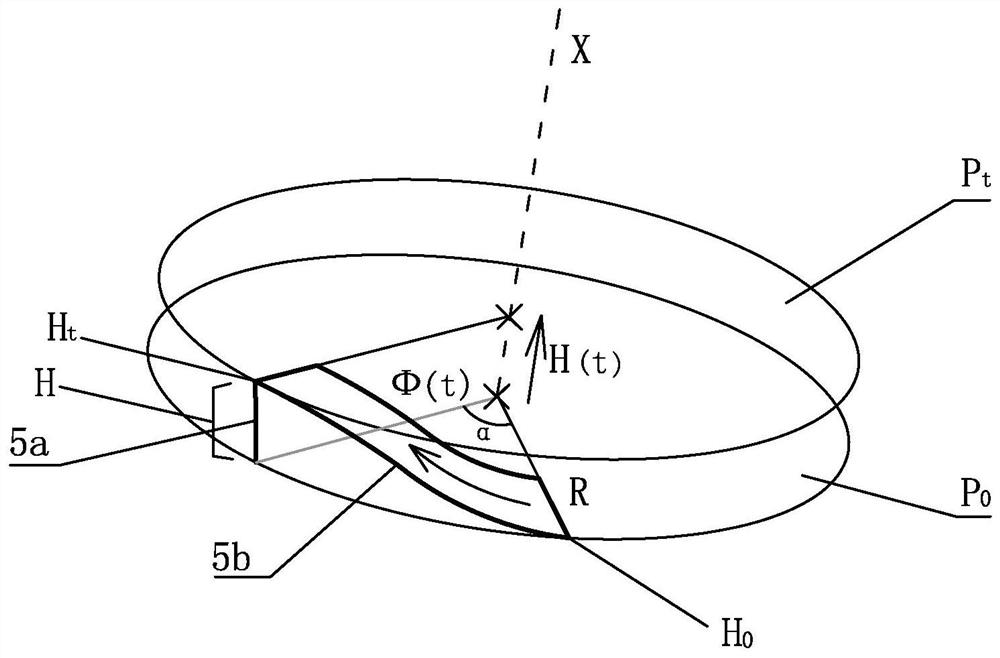

[0081] The opposite tooth surfaces of the first and second vibration gears of the vibration gear adopt the conventional tooth surface generation form:

[0082] When R does not intersect the axis, the formula middle and H(t) are both linear functions.

[0083] By drawing and processing the real object in this way, the torque of the relative rotation of the vibrating teeth is tested as follows:

[0084] project 10 20 30 40 50 60 70 80 90 100 Example 1 device 1 1.6 1.6 1.7 1.7 2.1 5.3 N / A N / A N / A N / A Example 1 device 2 1.5 1.6 1.7 1.9 4.3 N / A N / A N / A N / A N / A Example 1 device 3 1.7 1.6 1.8 2.0 5.7 N / A N / A N / A N / A N / A Example 1 device 4 1.6 1.6 1.7 1.8 1.9 2.7 6.1 N / A N / A N / A Example 1 device 5 1.6 1.6 1.7 1.7 2.1 3.1 5.8 N / A N / A N / A Example 1 device 6 1.5 1.5 1.6 1.6 1.9 4.6 N / A N / A N / A N / A Example 1 device 7 1.6 1.5 1.6 1.8 2.2 5.3 ...

Embodiment 2

[0089] When R intersects the axis, the formula middle and H(t) are both linear functions. Pass

[0090] By drawing and processing the real object in this way, the torque of the relative rotation of the vibrating teeth is tested as follows:

[0091] project 10 20 30 40 50 60 70 80 90 100 Example 1 device 1 2.3 2.3 2.3 2.4 2.3 2.3 2.3 2.3 2.3 2.3 Example 1 device 2 2.2 2.3 2.3 2.3 2.3 2.3 2.4 2.3 2.4 2.3 Example 1 device 3 2.3 2.2 2.3 2.3 2.4 2.4 2.3 2.3 2.3 2.4 Example 1 device 4 2.2 2.3 2.3 2.2 2.3 2.3 2.3 2.4 2.3 2.3 Example 1 device 5 2.4 2.3 2.3 2.4 2.3 2.3 2.2 2.3 2.3 2.3 Example 1 device 6 2.3 2.2 2.3 2.3 2.2 2.3 2.4 2.3 2.3 2.3 Example 1 device 7 2.2 2.3 2.2 2.3 2.3 2.3 2.3 2.3 2.3 2.3 Example 1 device 8 2.2 2.3 2.3 2.2 2.3 2.3 2.3 2.3 2.4 2.3 Example 1 device 9 2.3 2.4 2.3 2.3 2.2 2.3 2.3 2.4 2.3 2.3 Example o...

Embodiment 3

[0096] When R intersects the axis, the formula middle is a quadratic function, and H(t) is a one-time function.

[0097] By drawing and processing the real object in this way, the torque of the relative rotation of the vibrating teeth is tested as follows:

[0098]

[0099]

[0100] Note: 10, 20 to 100 represent the average torque recorded every ten times.

[0101] It can be seen from the data that the torque does not show an increasing trend with the increase of the number of vibrations in this way, and the relative rotation torque of the vibrating teeth is relatively average, and the average value is moderate.

[0102] The vibrating tooth surface of the disassembly device is relatively complete. The analysis reason is that this kind of curved surface will become line contact during the relative rotation process, and no friction will occur in long-term line contact. Since the line contact reduces friction, the static electricity generated by the relative surface con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com