Polylactic acid/ZIF-8@C600 composite material and preparation method and application thereof

A technology of ZIF-8 and composite materials, applied in chemical instruments and methods, rayon manufacturing, and other chemical processes, can solve the problems of insufficient economy and energy saving, cumbersome porous operation, etc., and achieve improved oil-water separation performance and surface roughness , The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

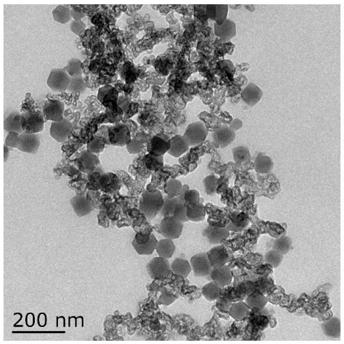

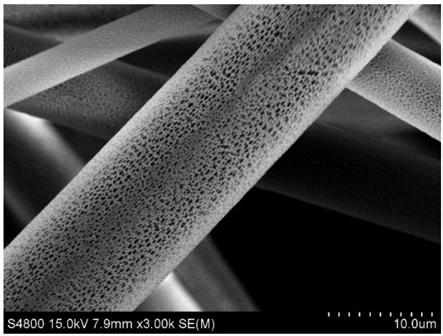

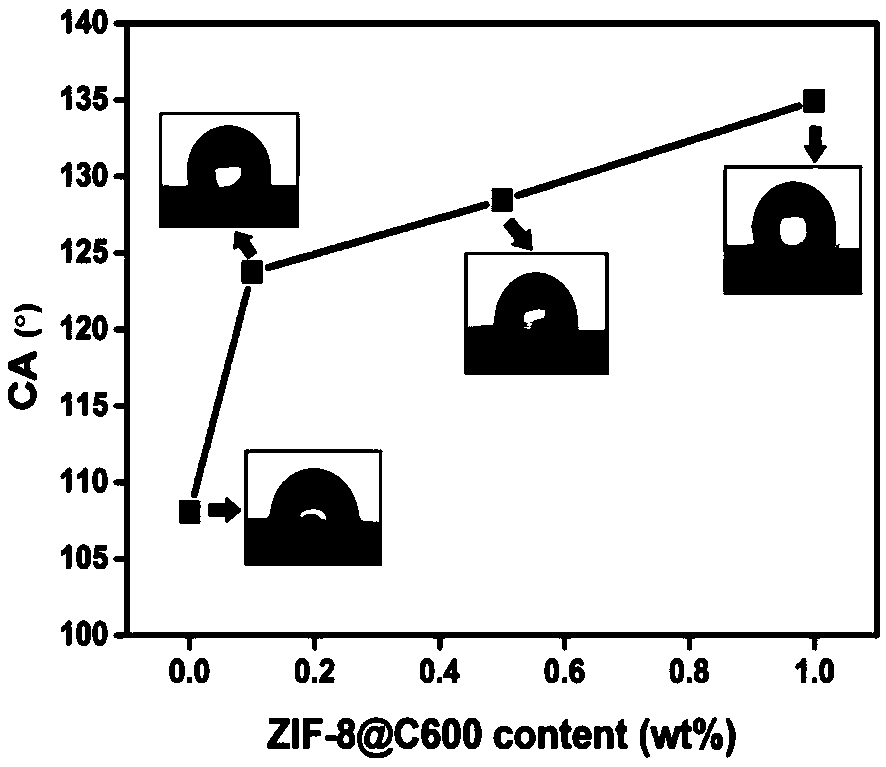

Embodiment 1

[0030] Weigh 1.5g of carbon black particles in 750mL of hydrochloric acid, ultrasonically reflux in a water bath at 60°C for 3h, filter and wash with water until neutral, and dry under vacuum at 110°C for 12h to obtain purified carbon black. Weigh 1.5g of purified carbon black in 750mL of nitric acid and hydrogen peroxide mixed solution, ultrasonically reflux at 60°C in a water bath for 4h, filter and wash with water until neutral, then dry under vacuum at 110°C for 12h to obtain oxidized carbon black, which is easy to dissolve in methanol Dispersed carbon black. Weigh 0.489g of oxidized carbon black in 300mL of methanol, stir for 2h, and then ultrasonically disperse for 2h. Dissolve 4.806g of 2-methylimidazole in 300mL of methanol, and simultaneously weigh 4.461g of zinc nitrate hexahydrate and dissolve in 300mL of methanol, then immediately pour it into the methanol solution of 2-methylimidazole to mix the two evenly, and then oxidize The methanol dispersion of carbon black...

Embodiment 2

[0033] Weigh 1.5g of carbon black particles in 750mL of hydrochloric acid, ultrasonically reflux in a water bath at 60°C for 3h, filter and wash with water until neutral, and dry under vacuum at 110°C for 12h to obtain purified carbon black. Weigh 1.5g of purified carbon black in 750mL of nitric acid and hydrogen peroxide mixed solution, ultrasonically reflux at 60°C in a water bath for 4h, filter and wash with water until neutral, then dry under vacuum at 110°C for 12h to obtain oxidized carbon black, which is easy to dissolve in methanol Dispersed carbon black. Weigh 0.489g of oxidized carbon black in 300mL of methanol, stir for 2h, and then ultrasonically disperse for 2h. Dissolve 4.806g of 2-methylimidazole in 300mL of methanol, and simultaneously weigh 4.461g of zinc nitrate hexahydrate and dissolve in 300mL of methanol, then immediately pour it into the methanol solution of 2-methylimidazole to mix the two evenly, and then oxidize The methanol dispersion of carbon black...

Embodiment 3

[0036] Weigh 1.5g of carbon black particles in 750mL of hydrochloric acid, ultrasonically reflux in a water bath at 60°C for 3h, filter and wash with water until neutral, and dry under vacuum at 110°C for 12h to obtain purified carbon black. Weigh 1.5g of purified carbon black in 750mL of nitric acid and hydrogen peroxide mixed solution, ultrasonically reflux at 60°C in a water bath for 4h, filter and wash with water until neutral, then dry under vacuum at 110°C for 12h to obtain oxidized carbon black, which is easy to dissolve in methanol Dispersed carbon black. Weigh 0.489g of oxidized carbon black in 300mL of methanol, stir for 2h, and then ultrasonically disperse for 2h. Dissolve 4.806g of 2-methylimidazole in 300mL of methanol, and simultaneously weigh 4.461g of zinc nitrate hexahydrate and dissolve in 300mL of methanol, then immediately pour it into the methanol solution of 2-methylimidazole to mix the two evenly, and then oxidize The methanol dispersion of carbon black...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com