La, Er, Co and Mn co-doped BFO film with resistance switching effect and preparation method of film

A resistance switch and effect technology, applied in the field of BFO film and its preparation, can solve the problems of thin film leakage conduction, ferroelectric performance reduction, adverse effects of thin film resistance switching effect, etc., to achieve easy reaction, simple preparation method, and easy preparation process The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The La, Er, Co, Mn co-doped BiFeO 3 The preparation method of film, its step is as follows:

[0033] Step 1: Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, La(NO 3 ) 3 ·nH 2 O, Er(NO 3 ) 3 ·6H 2 O, C 4 h 6 MnO 4 4H 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in ethylene glycol methyl ether, after stirring evenly, add acetic anhydride and continue stirring until uniformly to obtain a precursor solution;

[0034] Step 2: Spin-coat the precursor solution on the FTO / Glass substrate to obtain a wet film, bake the wet film at 195-200°C to obtain a dry film, and then rapidly anneal at 500-550°C to obtain crystalline Bi 0.9-x La x Er 0.1 Fe 0.96 co 0.02 mn 0.02 o 3 film;

[0035] Step 3: The crystalline Bi 0.9-x La x Er 0.1 Fe 0.96 co 0.02 mn 0.02 o 3 The film is cooled to room temperature, and step 2 is repeated to obtain a preset thickness of Bi 0.9-x La x Er 0.1 Fe 0.96 co 0.02 mn 0.02 o 3 film.

[0036] In step 1, the total concentration of m...

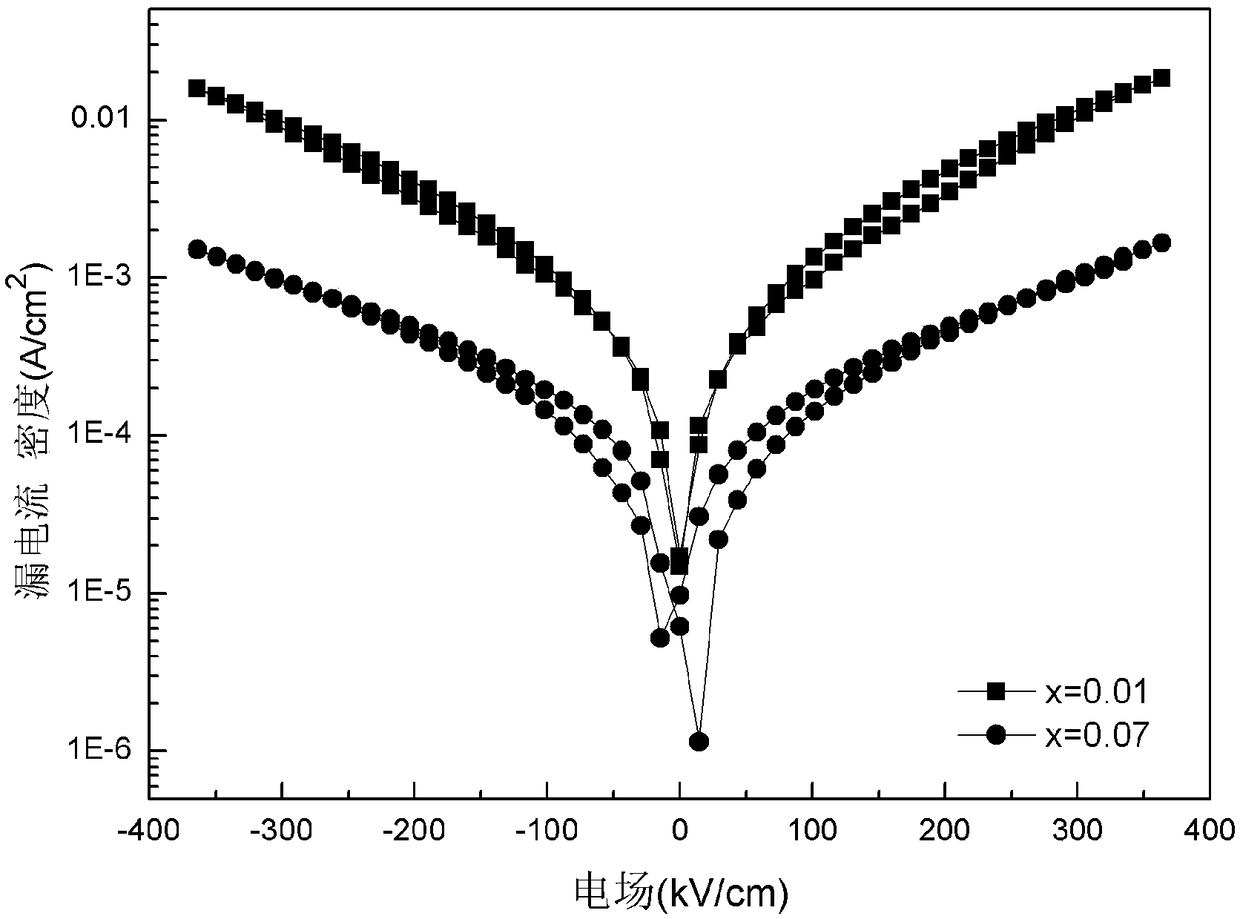

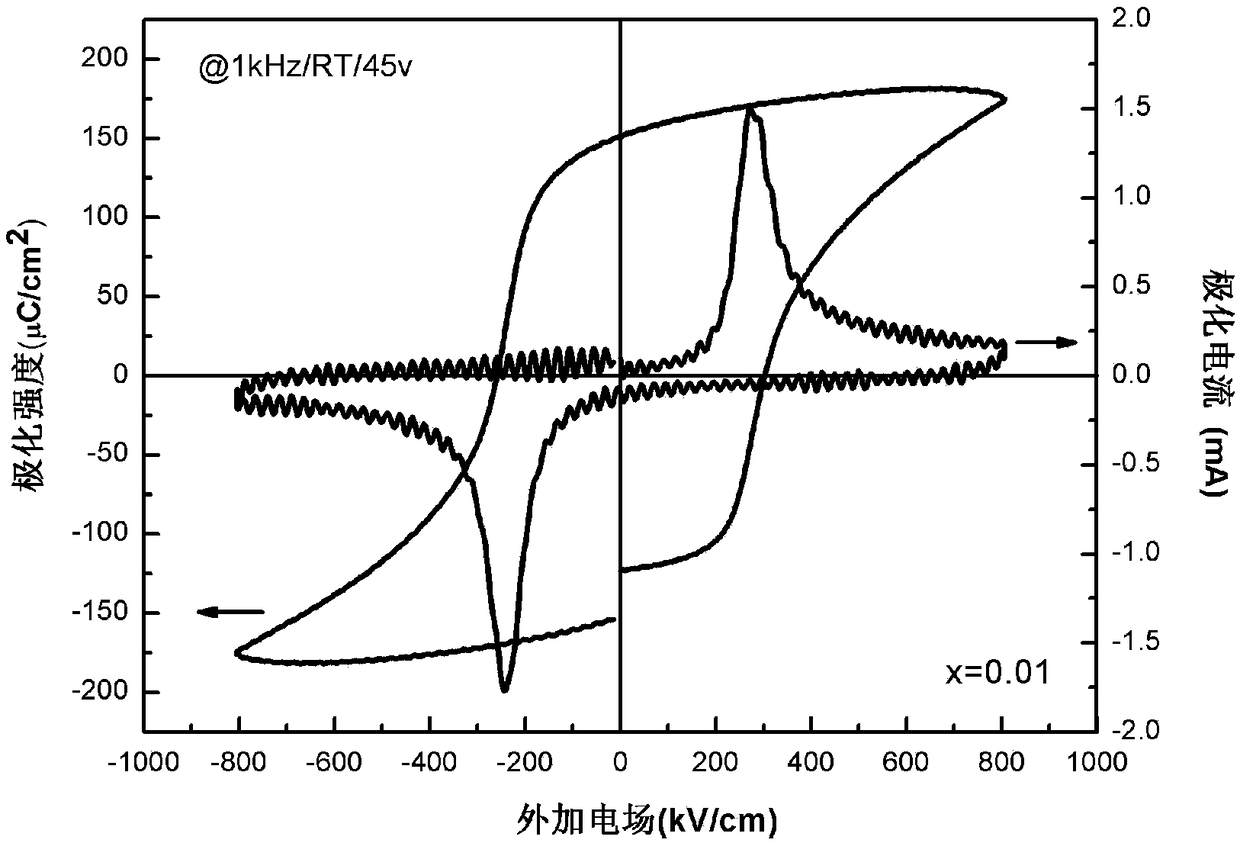

Embodiment 1

[0047] 1) Bi(NO 3 ) 3 ·5H 2 O, La(NO 3 ) 3 ·nH 2 O, Er(NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Co(NO 3 ) 2 ·6H 2 O and C 4 h 6 MnO 4 4H 2 O is dissolved in ethylene glycol methyl ether in a molar ratio of 0.94:0.01:0.1:0.96:0.02:0.02, stirred for 1.5h, then added with acetic anhydride and stirred for 30min to obtain a stable Bi 0.89 La 0.01 Er 0.1 Fe 0.96 co 0.02 mn 0.02 o 3 Precursor solution, the precursor solution was left to stand for 24h; wherein, Bi 0.89 La 0.01 Er 0.1 Fe 0.96 co 0.02 mn 0.02 o 3 The total metal ion concentration in the precursor solution is 0.3mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0048] 2) Spin coating Bi on FTO / Glass substrate by spin coating method 0.89 La 0.01 Er 0.1 Fe 0.96 co 0.02 mn 0.02 o 3 Precursor solution, the mixing speed is 4000r / min, the mixing time is 20s, the wet film is prepared, the wet film is baked at 195°C for 8min to obtain the dry film, and th...

Embodiment 2

[0051] 1) Bi(NO 3 ) 3 ·5H 2 O, La(NO 3 ) 3 ·nH 2 O, Er(NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Co(NO 3 ) 2 ·6H 2 O and C 4 h 6 MnO 4 4H 2 O is dissolved in ethylene glycol methyl ether in a molar ratio of 0.92:0.03:0.1:0.96:0.02:0.02, stirred for 1.5h, then added with acetic anhydride and stirred for 30min to obtain a stable Bi 0.87 La 0.03 Er 0.1 Fe 0.96 co 0.02 mn 0.02 o 3 Precursor solution, the precursor solution was left to stand for 24h; wherein, Bi 0.87 La 0.03 Er 0.1 Fe 0.96 co 0.02 mn 0.02 o 3 The total metal ion concentration in the precursor solution is 0.3mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0052] 2) Spin coating Bi on FTO / Glass substrate by spin coating method 0.87 La 0.03 Er 0.1 Fe 0.96 co 0.02 mn 0.02 o 3 Precursor solution, the mixing speed is 4000r / min, the mixing time is 20s, the wet film is prepared, the wet film is baked at 195°C for 8min to obtain the dry film, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com