A 750kV shunt reactor high-voltage outlet structure

A high-voltage outgoing line and reactor technology, which is applied in the direction of transformer/reactor installation/support/suspension, transformer/inductor coil/winding/connection, circuit, etc. Cutting effect, improve the anti-seismic ability, and ensure the effect of long-term safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

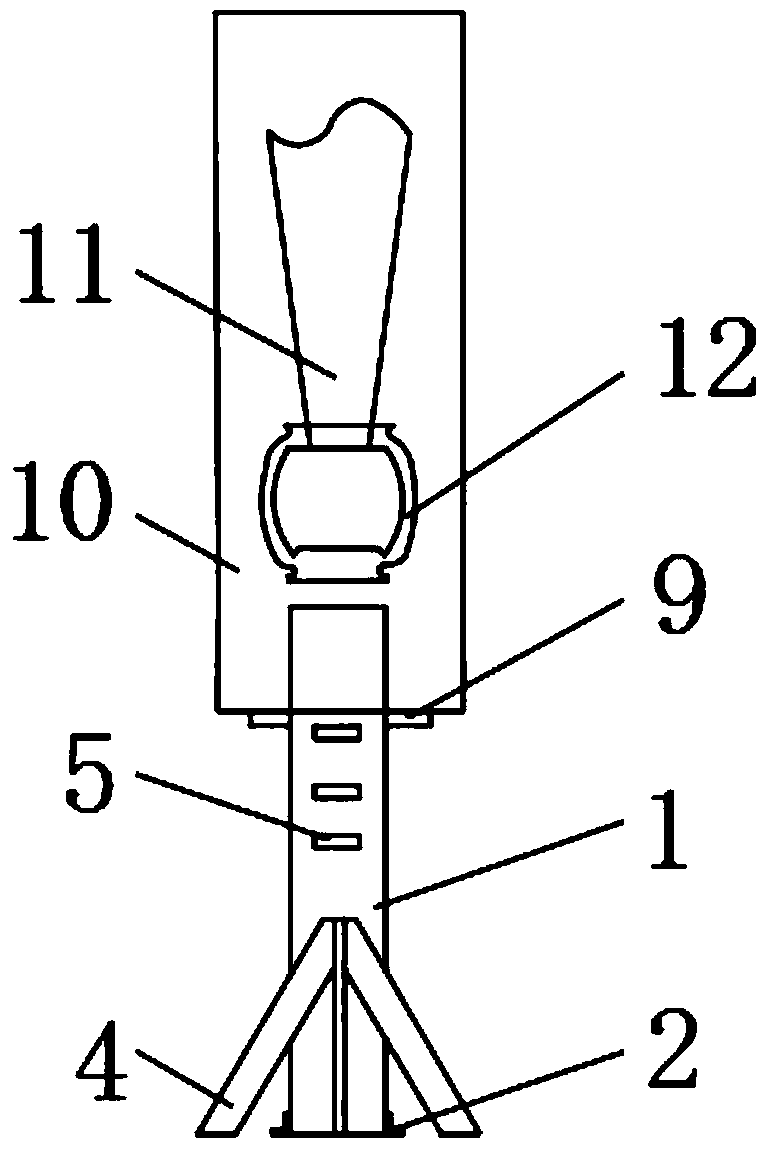

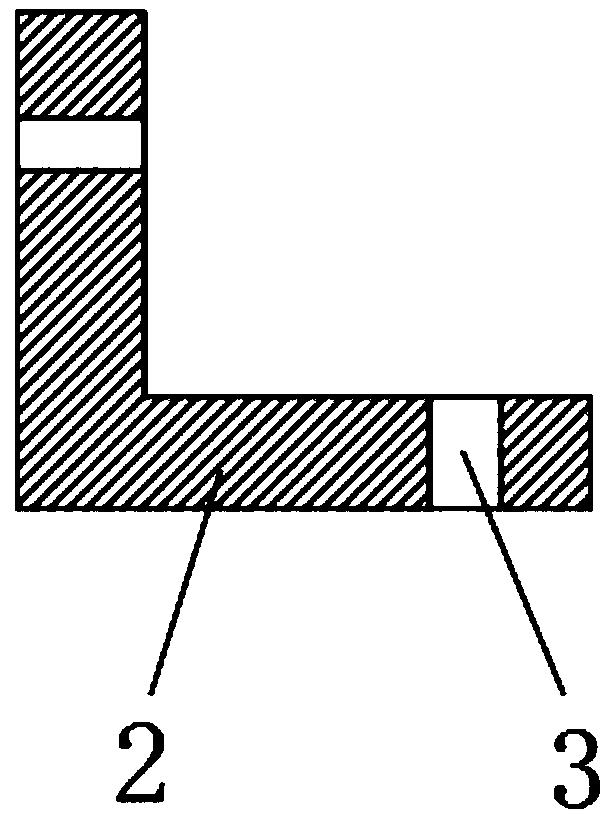

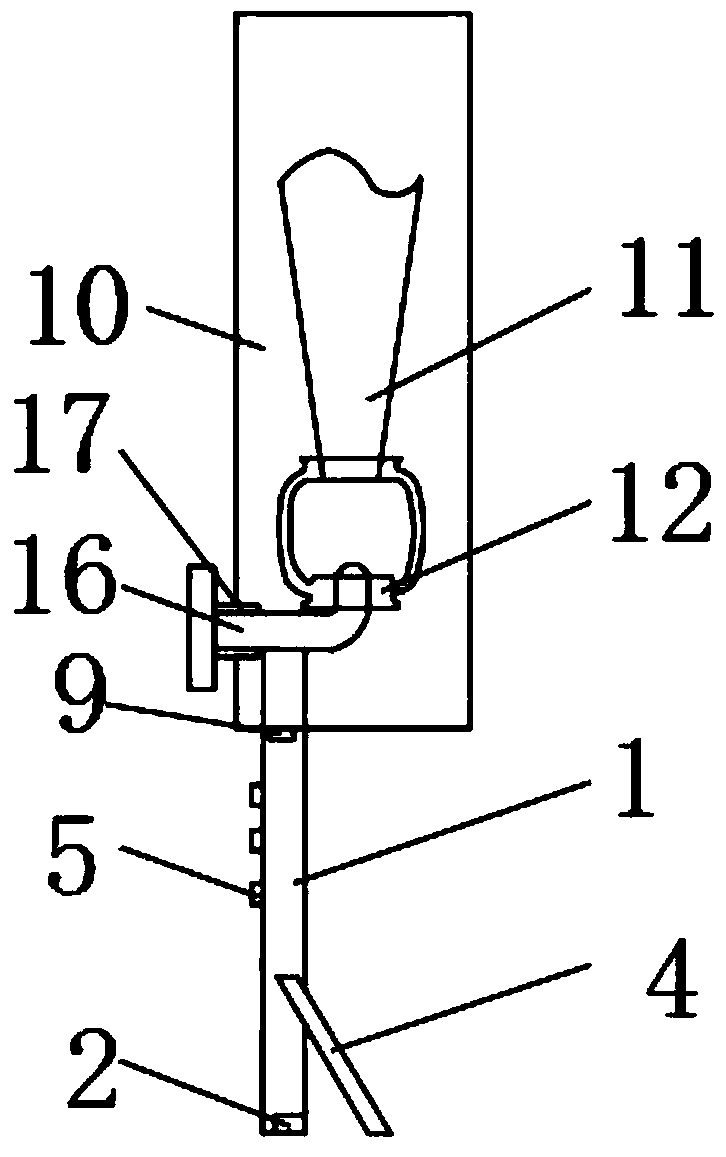

[0018] Such as Figure 1-5 As shown, a 750KV shunt reactor high-voltage outlet structure includes a raised seat 1, and the bottom of the raised seat 1 near both sides is fixed with L-shaped fixing blocks 2, and the L-shaped fixed block 2 is provided with a plurality of fixing holes 3. A plurality of support blocks 4 are connected to the middle part of the raised seat 1, and a plurality of wire clips 5 are fixedly installed on the surface of the raised seat 1. The wire clips 5 are in the shape of a rectangular frame, and the outer side thereof is provided with a threaded groove 6, and the threaded groove 6 The threaded pin 7 is connected to the internal thread of the threaded pin 7, and the end of the threaded pin 7 is provided with a cushion block 8, and the top of the raised seat 1 is connected with an insulating paper tube 10 through a fastener 9, and the inside of the insulating paper tube 10 is provided near the top. The casing 11, the bottom of the casing 11 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com