Fault early-warning device for polyimide film production equipment

A polyimide film and production equipment technology, applied in the field of polyimide film production equipment failure warning devices, can solve problems such as motor damage and production accidents, and achieve the effect of reducing the impact and the possibility of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

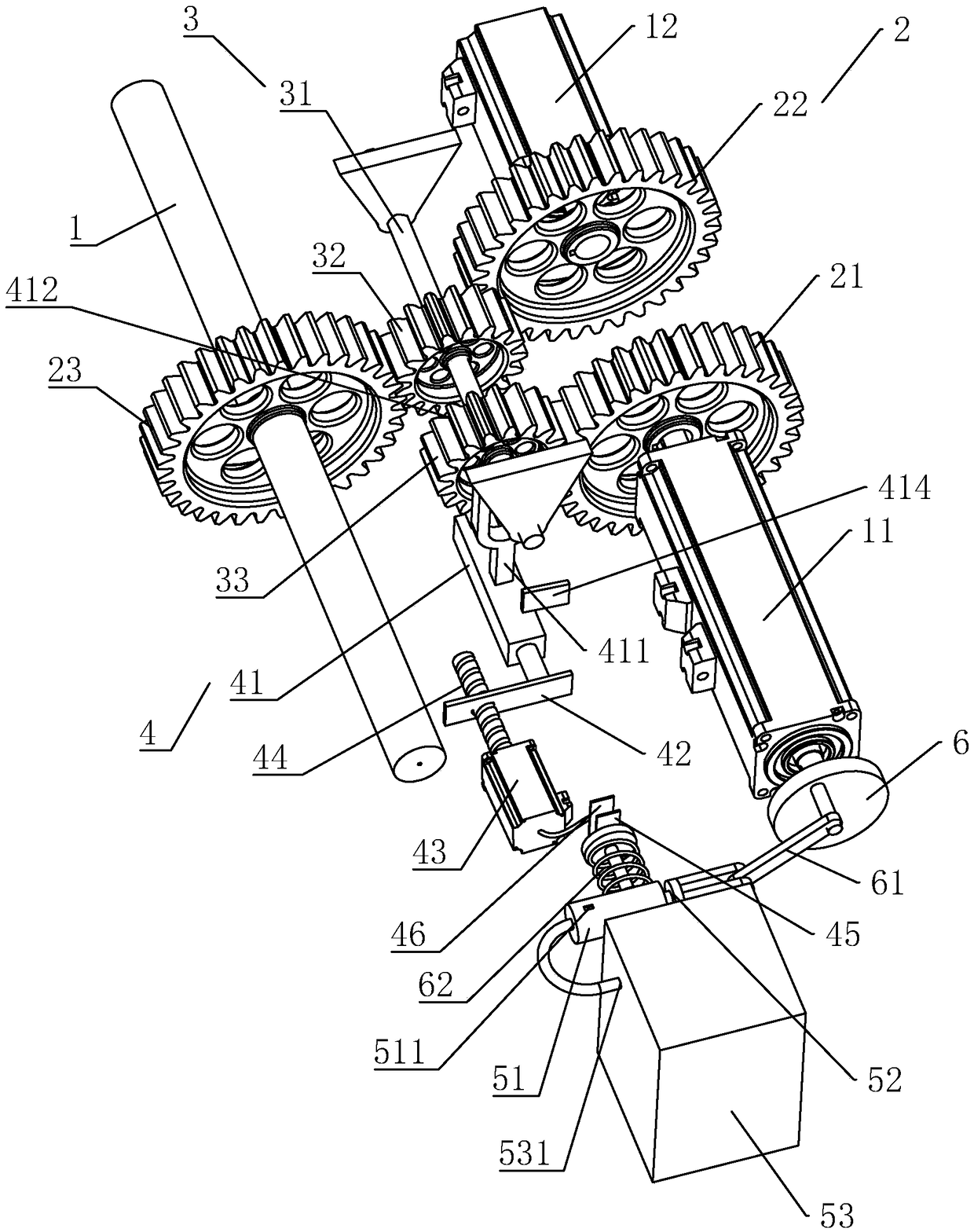

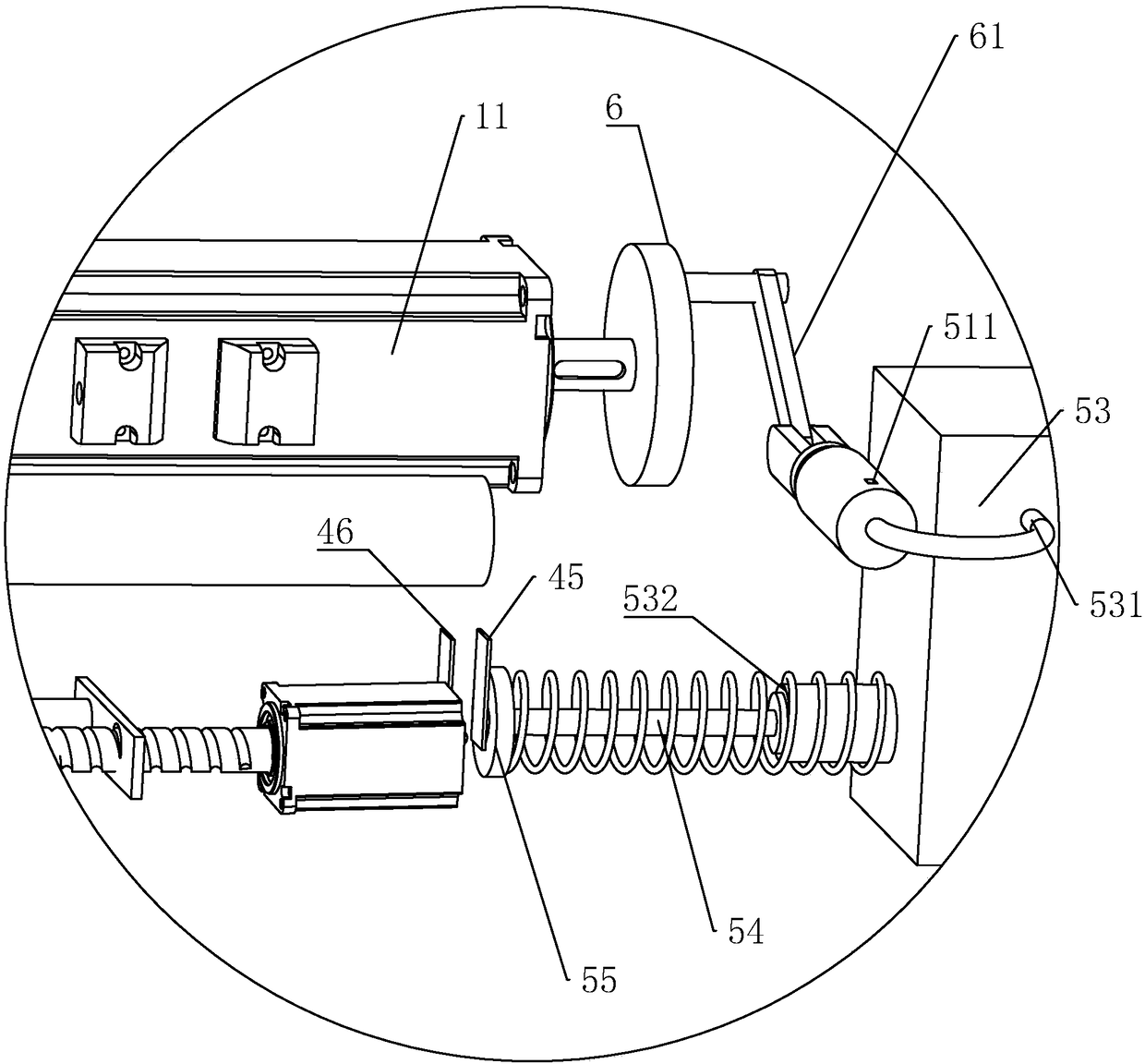

[0032] This embodiment provides a polyimide film production equipment fault warning device, the structure is as follows figure 1 and figure 2 Shown, comprise body 1 and be located at the working motor 11 on the body 1, through gear transmission between working motor 11 and polyimide film production equipment, working motor 11 is provided with the spare motor 12 parallel with it outside, working motor The output shaft of 11 is provided with driving gear 21, and the output shaft of backup motor 12 is correspondingly provided with the backup gear 22 identical in structure with driving gear 21, and polyimide film production equipment is provided with driven gear 23, and working motor 11 There is a transmission member 2 outside, which is used for transmission between the driving gear 21 or the backup gear 22 and the driven gear 23 .

[0033] The working motor 11 is provided with an adjusting part 3, which is used to switch the transmission part 2 between the driving gear 21 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com