Automatic arranging device for chip injection molding machine

An injection molding machine and automatic technology, applied in sports accessories, roulette games, indoor games, etc., can solve problems such as rising production costs, personal safety hazards, slow placement speed, etc., achieve reliable work, improve automation level, and place speed up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

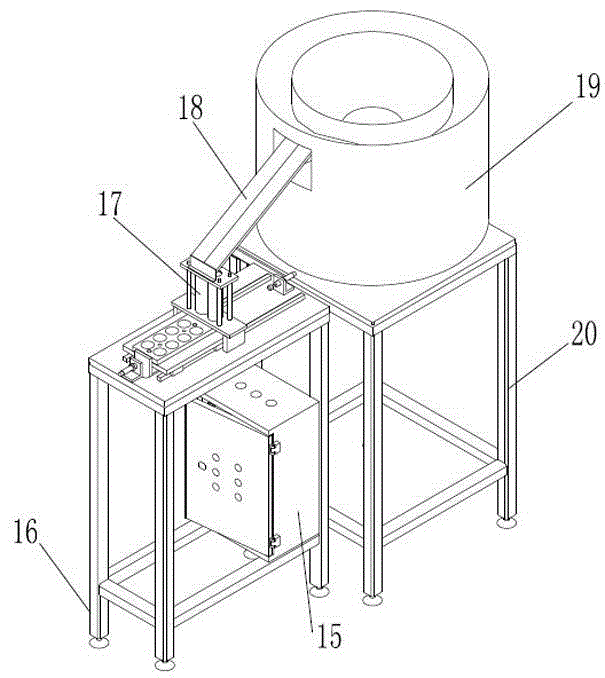

[0015] Such as figure 1 As shown, the automatic placement equipment of the chip injection molding machine described in this embodiment includes a first frame 16 and a second frame 20, and the first frame 16 is provided with a fixed support plate 1 and an electric control box 15 , the fixed support plate 1 is provided with an automatic placement mechanism 17, and the automatic placement mechanism 17 is provided with a guide tube 9; the second frame 20 is provided with a vibrating plate 19, and the vibrating plate 19 A guide mechanism 18 is provided at the place, and one end of the guide mechanism 18 is connected with one end of the guide tube 9, and the electric control box 15 is electrically connected with the automatic placement mechanism 17 and the vibrating plate 19; 15 Make the vibrating plate 19 vibrate, and the inserts vibrate out from the discharge port along the guide mechanism and enter the guide tube 9 in the automatic swing mechanism, so that the inserts are stacked...

Embodiment 2

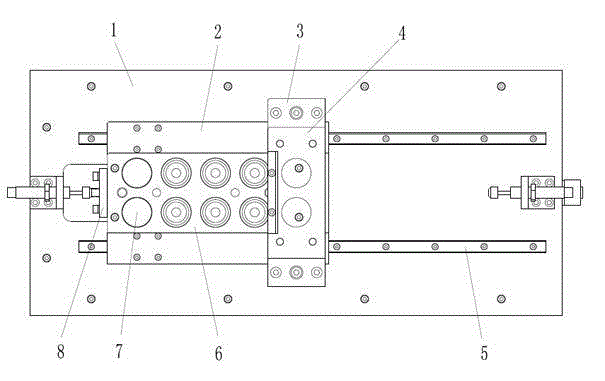

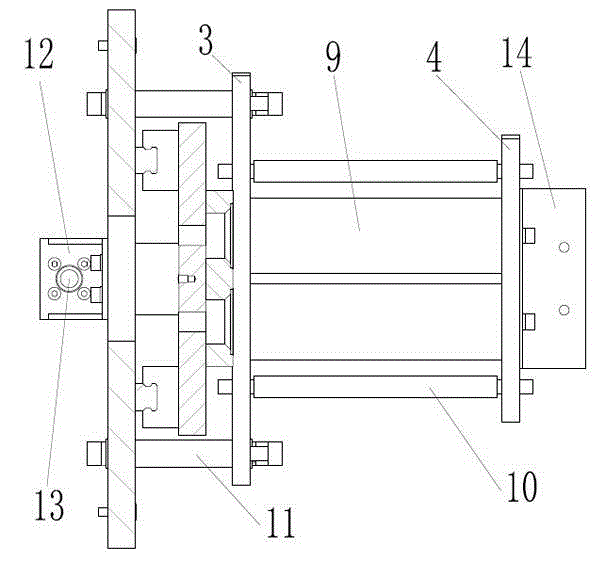

[0018] Such as figure 2 , image 3 As shown, the automatic placement equipment of the chip injection molding machine described in this embodiment is different from Embodiment 1 in that the automatic placement mechanism 17 includes a fixed plate backing plate 2, a collision block 8, a round tube lower pressure plate 3, a round tube Upper platen 4, platen seat 11, studs 10, cylinder piston rod 13 and product fixing plate 6; the fixed support plate 1 is provided with a ball linear guide 5, and the ball linear guide 5 is movably connected to the fixed plate backing plate 2 ; The two ends of the plate base 11 are supported and fixed between the fixed support plate 1 and the lower platen 3 of the circular tube; the guide tube 9 is located between the upper platen 4 of the circular tube and the lower platen 3 of the circular tube, through The stud 10 connects the upper platen 4 of the round pipe and the lower platen 3 of the round pipe to compress the guiding round pipe 9; the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com