Multi-scale reinforced low/negative thermal expansion magnesium-based composite material and preparation method thereof

A negative thermal expansion, composite material technology, applied in the field of multi-scale reinforced low/negative thermal expansion magnesium matrix composites and their preparation, can solve the problems of huge difference in thermal expansion coefficient, interlayer cracking, etc., so as to reduce the difference in thermal expansion coefficient and avoid easy Aging, the effect of overcoming adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

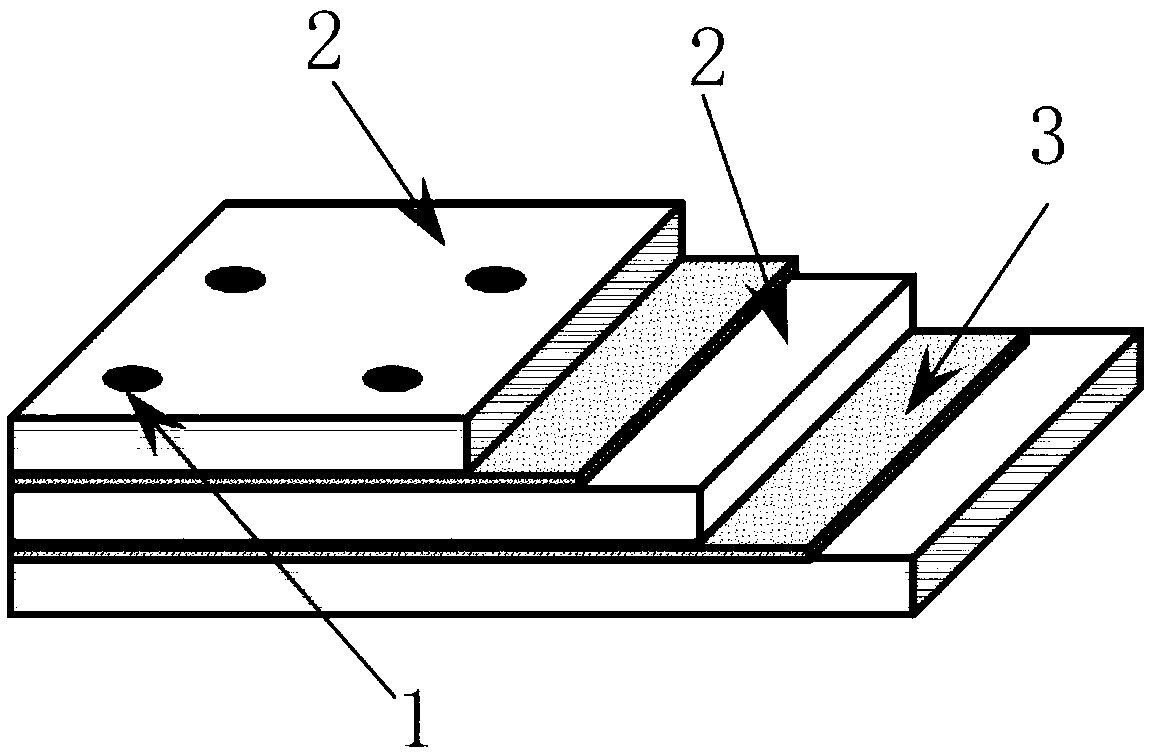

[0044] Wherein, the preparation method of the reinforcement comprises the following steps:

[0045] 1) laying a single layer of fiber without weft or fiber fabric to make a continuous fiber layer;

[0046] 2) uniformly distribute quantitative negative expansion particles on the surface and inside of the single-layer fiber non-weft cloth or fiber fabric;

[0047] 3) Prepare the single-layer fiber non-woven fabric or fiber fabric with negative expansion particles prepared in step 2) into the required laminate preform according to the required layering method, and perform Z-direction puncture reinforcement with punctured fiber bundles ;

[0048] 4) Put the prepared laminated prefabricated body into distilled water and ultrasonically treat it so that the negative expansion particles are more evenly distributed between the layers of the fiber fabric and between the fiber bundles. .

Embodiment 1

[0050] In this example, the base metal is AZ91D magnesium alloy, the solidus is 470°C, and the liquidus is 595°C; the continuous fiber layer is T700 carbon fiber non-weft cloth, and the layering method is unidirectional layering; the negative expansion particles are zirconium tungstate.

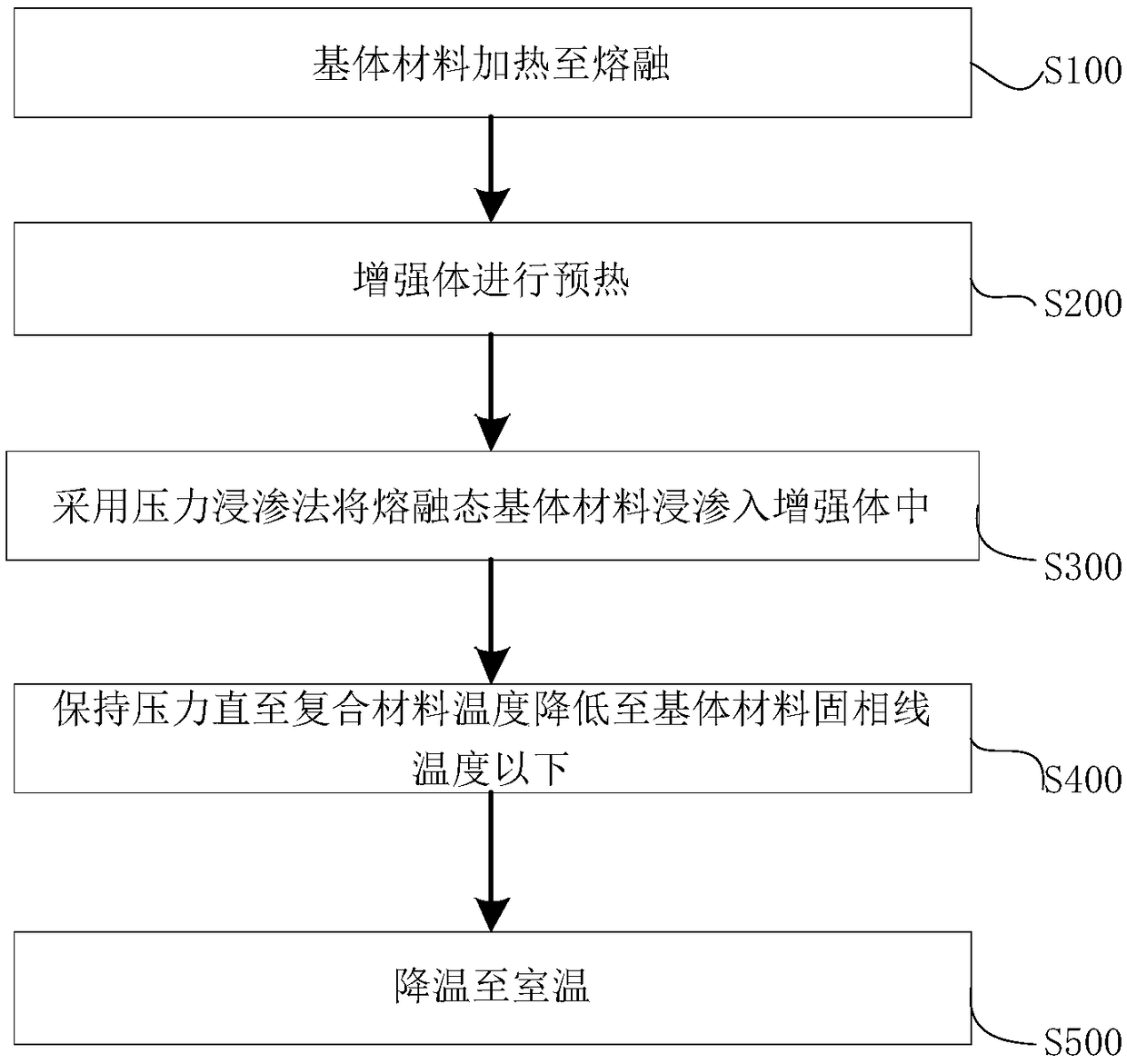

[0051] Prepare multi-scale reinforcements by laminating one layer of non-weft cloth and one layer of zirconium tungstate to ensure the same orientation of the fibers of the non-weft cloth. ; The thickness of the zirconium tungstate layer is 0.5 mm, and the distance between the punctured fibers in the Z direction is 20 times the diameter of the fiber bundle. Under the protection of Ar gas, melt AZ91D to 610°C and keep it warm for 45 minutes; put the reinforcement into the impregnation mold, and preheat the reinforcement base impregnation mold to 595°C under the protection of Ar gas, and keep it warm for 45 minutes; The alloy is injected into the extrusion die, and a press is used to apply an i...

Embodiment 2

[0054] In this example, the base metal is AZ91D magnesium alloy, the solidus is 470°C, and the liquidus is 595°C; the continuous fiber layer is T700 carbon fiber non-weft cloth, and the layering method is orthogonal layering; the negative expansion particles are zirconium tungstate.

[0055] The multi-scale reinforcement is prepared by laminating one layer of 0° no weft cloth, one layer of zirconium tungstate and one layer of 90° no weft cloth. The number of laminations of no weft cloth is 7 layers, and the thickness of each layer is one layer of no weft cloth. Cloth thickness: The thickness of the zirconium tungstate layer is 0.5mm, and the distance between the punctured fibers in the Z direction is 20 times the diameter of the fiber bundle. Under the protection of Ar gas, melt AZ91D to 620°C and keep it warm for 45 minutes; put the reinforcement into the impregnation mold, and preheat the reinforcement base impregnation mold to 595°C under the protection of Ar gas, and keep i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com