Melted steel dreg spiral crushing device and method

A crushing device and steel slag spiral technology, which is applied in the field of spiral crushing devices for high-temperature molten steel slag, can solve the problem that the crushing process is not continuous, reduce steel slag investment and production and operation costs, reduce system investment, and improve steel slag treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

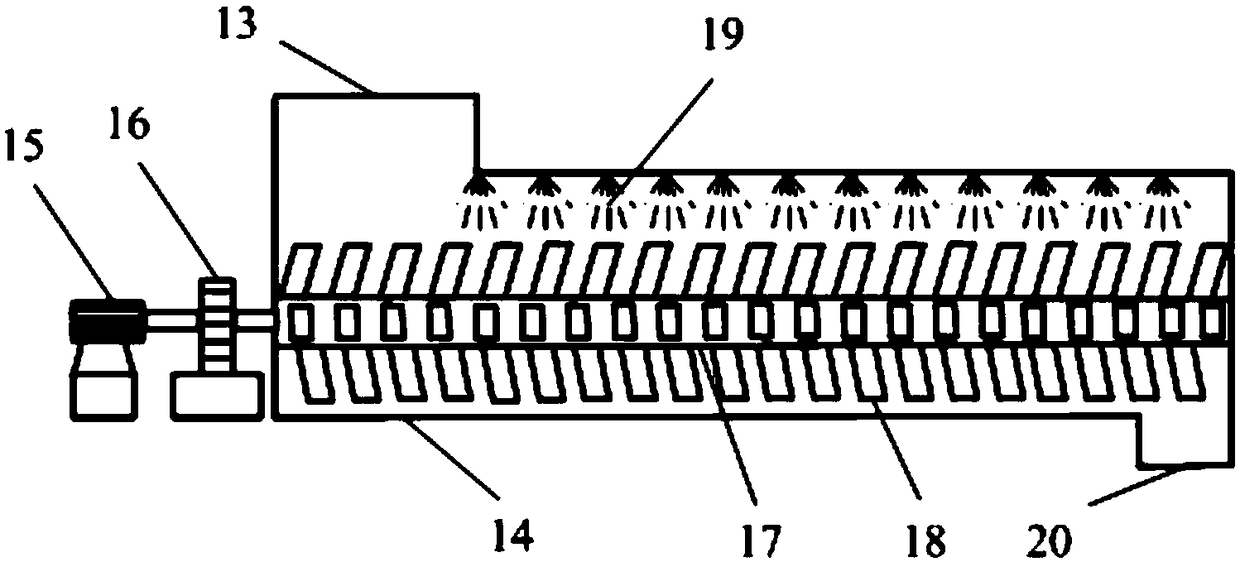

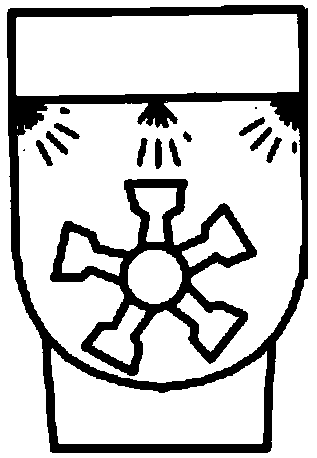

[0032] A rotary roller crushing device for molten steel slag such as figure 1 , Figure 2a -b and image 3 As shown, the spiral crushing device for molten steel slag includes: a slag tank 1, a tipping machine 2, a screw crusher 3, a slag tank 4, a slag discharger 5, a hot stuffy tank 6, a flue gas treatment system and a control system 12, preferably It is a PLC control system 12; the screw crusher 3 includes a slag discharge port 13, a crushing chamber 14, a driving device, a crushing shaft 17, a crushing tooth 18, a nozzle 19 and a slag discharge port 20; the slag discharge port 13 is arranged on the screw crusher 3, the slag outlet 20 is set at the rear end of the screw crusher 3, the crushing teeth 18 are set on the crushing shaft 17, and the crushing shaft 17 extends from the front end to the rear end of the screw crusher 3 and is located in the crushing chamber 14. The nozzle 19 is arranged on the upper part of the screw crusher 3, and is used to spray water to cool the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com