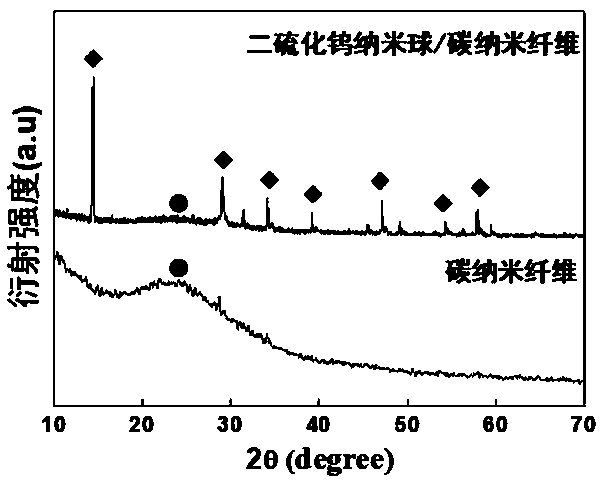

Preparation and application of tungsten disulphide nanosphere/carbon nano fibre composite material

A carbon nanofiber and tungsten disulfide technology, which is applied in the fields of tungsten compounds, analytical materials, and fiber chemical characteristics, can solve the problems of poor selectivity, metal toxicity, and low sensitivity, and achieve low cost, high sensitivity, and fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: the preparation method of a kind of tungsten disulfide nanosphere / carbon nanofiber composite material in this embodiment, is specifically carried out according to the following steps:

[0026] 1. Preparation of carbon nanofibers by electrospinning

[0027] 1) Dissolve 0.5-1.5 g of polyacrylonitrile powder in 5-15 mL of dimethylformamide solution, and heat and stir at a temperature of 70°C-140°C for 0.5-1.5 h to obtain an electrospinning solution; then , transfer 5-15 mL of the above solution into a syringe, fix the syringe on the syringe pump, and carry out electrospinning at a voltage of 15-25 KV, the flow rate of the solution is 0.5-1.5 mL / h, and the collection distance is 5-15 cm;

[0028] 2) Put the polyacrylonitrile fiber in a blast drying oven, raise the temperature to 250~350℃ at a speed of 1~3℃ / min, and keep it warm for 0.5~1.5h for stabilization treatment;

[0029] 3) Place the stabilized polyacrylonitrile fiber in the center of the t...

specific Embodiment approach 2

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1 1), 1 g of polyacrylonitrile powder is dissolved in 10 mL of dimethylformamide solution, and stirred at a temperature of 100 ° C for 1 h, The electrospinning solution was obtained, and the solution was transferred to a 10 mL syringe, and then the syringe was fixed on the syringe pump. The electrospinning voltage was controlled at 120 KV, the distance from the receiving device to the spinning needle was 10 cm, and the solution flow rate was 1mL / h, electrospinning in an electrospinning device to obtain polyacrylonitrile fibers; others are the same as in Embodiment 1;

specific Embodiment approach 3

[0035]Specific embodiment 3: The difference between this embodiment and one of specific embodiments 1 to 2 is that in step 1 3), the polyacrylonitrile fiber after step 2) after the stabilization treatment is placed in the center of the tube furnace tube, and the temperature is 1 ° C / The temperature was raised to 300°C at a speed of 1 min, and the temperature was maintained for 1 hour for stabilization treatment; the stabilized polyacrylonitrile fiber was placed in the center of the tube furnace, and the temperature was raised from room temperature to 900°C at a rate of 5°C / min under the protection of argon. , keep warm for 60 minutes, and then cool down to room temperature with the furnace to obtain carbon nanofibers. The flow rate of argon gas described in step 1) is 400 sccm; the others are the same as in one of the specific embodiments 1 to 2;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com