PVA-based polyion composite membrane for industrial concentrated salt sewage treatment and preparation method thereof

A sewage treatment and polyion technology, applied in the direction of osmosis/dialysis water/sewage treatment, chemical instruments and methods, membranes, etc., can solve the problem of small water flux, low salt rejection rate and flux, and hydrothermal stability of molecular sieve inorganic membranes Insufficient performance and other problems, to achieve the effect of improving water flux, large permeation flux, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

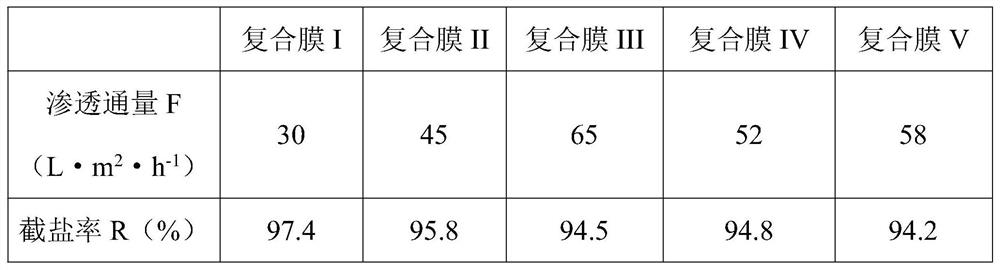

Examples

Embodiment 1

[0023] Embodiment 1 is used for the preparation of the PVA-based polyion composite membrane I of industrial concentrated salt sewage treatment

[0024] Step 1, the preparation of polyquaternium cationic PVA: the KOH solution that mass concentration is 5mol / L is stirred dropwise to PVA aqueous solution alkalization, then adds (3-chloro-2-hydroxymethyl) trimethyl ammonium chloride , the mass volume ratio of (3-chloro-2-hydroxymethyl)trimethylammonium chloride, KOH solution and PVA aqueous solution is 0.5g: 1ml: 100ml, stirring and reacting at 60-85°C for 1-3h, After the reaction, adding mass fraction is 95% ethanol, separating the precipitate, separating, washing and drying the precipitate to obtain polyquaternium cationic PVA with a degree of substitution of 2.5;

[0025] Preparation of polysulfonic acid group-substituted anion PVA: Stir and drop concentrated sulfuric acid into PVA aqueous solution, wherein the mass volume ratio of concentrated sulfuric acid to PVA aqueous solu...

Embodiment 2

[0030] Example 2 Preparation of PVA-based Polyion Composite Membrane II for Industrial Concentrated Salt Wastewater Treatment

[0031] Step 1, the preparation of polyquaternium cationic PVA: the KOH solution that mass concentration is 10mol / L is stirred dropwise to PVA aqueous solution alkalization, then adds (3-chloro-2-hydroxymethyl) trimethyl ammonium chloride , the mass volume ratio of (3-chloro-2-hydroxymethyl)trimethylammonium chloride, KOH solution and PVA aqueous solution is 5g: 10ml: 100ml, stirred and reacted at 60-85°C for 1-3h, and reacted After finishing, adding mass fraction is 95% ethanol, separates precipitate, separates, washes, dries the precipitate, obtains the polyquaternium cationic PVA that substitution degree is 7;

[0032] Preparation of polysulfonic acid group-substituted anion PVA: Stir and drop concentrated sulfuric acid into PVA aqueous solution, wherein the mass volume ratio of concentrated sulfuric acid to PVA aqueous solution is 3g: 100ml, stir a...

Embodiment 3

[0037] Example 3 Preparation of PVA-based Polyion Composite Membrane III for Industrial Concentrated Salt Wastewater Treatment

[0038] Step 1, the preparation of polyquaternium cationic PVA: the KOH solution that mass concentration is 6.5mol / L is stirred dropwise to PVA aqueous solution alkalization, then adds (3-chloro-2-hydroxymethyl) trimethyl chloride Ammonium, the mass volume ratio of (3-chloro-2-hydroxymethyl)trimethylammonium chloride, KOH solution and PVA aqueous solution is 1.5g: 4ml: 100ml, stirring and reacting at 60-85°C for 1-3h , after the reaction is finished, add mass fraction and be 95% ethanol, isolate precipitate, separate, wash, dry by precipitate, obtain the degree of substitution and be the polyquaternium cationic PVA of 3.5;

[0039] Preparation of polysulfonic acid group-substituted anion PVA: Stir and drop concentrated sulfuric acid into PVA aqueous solution, wherein the mass volume ratio of concentrated sulfuric acid to PVA aqueous solution is 1.5g: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com