Preparation method of China-hemp tofu and product of preparation method

A technology for hemp and tofu, which is applied in the field of preparation of hemp tofu, can solve the problems such as the inability of hemp tofu to form a stable network gelling system, poor elasticity and hardness of hemp tofu, and uneven overall organization, and achieves good taste, Good water retention and strong elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 hemp tofu

[0045] (1) Pre-swelling: select the mildew-free shelled hemp seeds and wash them to soften with steam. The steam pressure used is 2MPa;

[0046] (2) Refining and slag removal: refine the fully swollen hemp seeds and water at a ratio of 1:5, and pass through 100 meshes to obtain hemp milk; dry the filtered filter residue and then perform ultrafine grinding to obtain hemp milk. hemp dietary fiber;

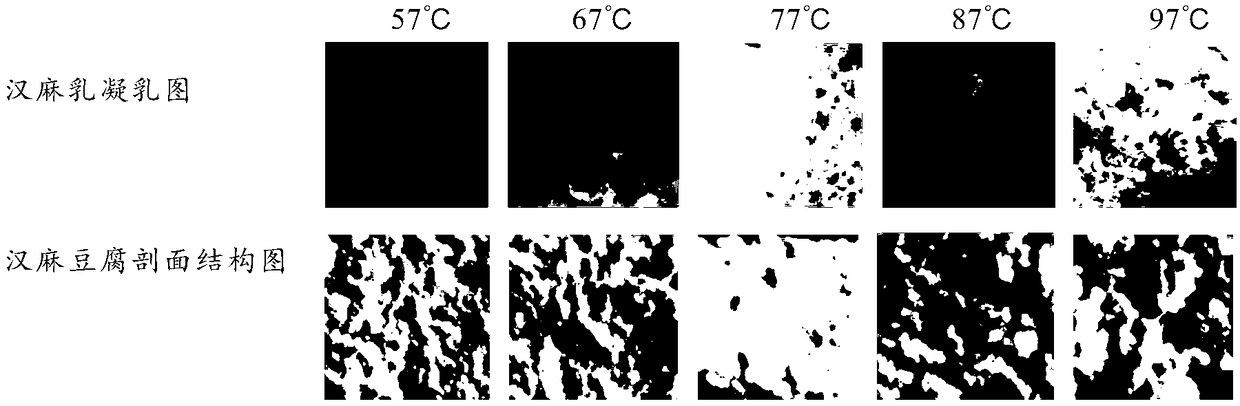

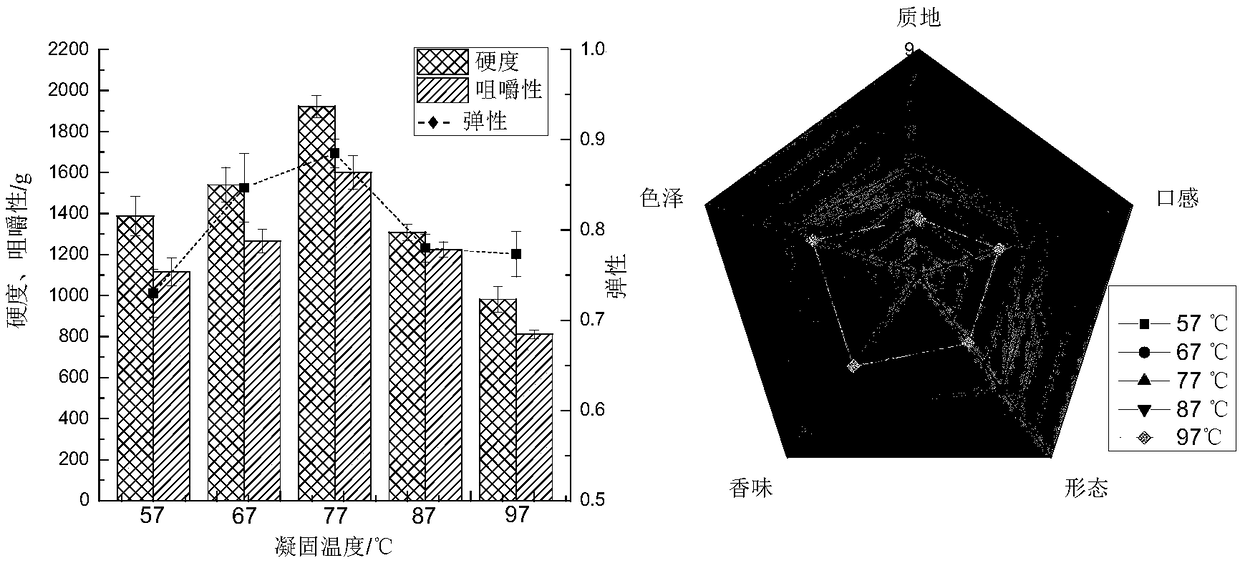

[0047] (3) Thermal coagulation: Hemp milk is slowly heated to 75°C in a boiling water bath for 30 minutes, then cooled to 45°C in a water bath;

[0048] (4) TG enzyme cross-linking: adding 1‰ of the total amount of hemp protein to activate TG enzyme (16000u / g) at 50°C in advance, and keeping it at 50°C for 60 minutes to solidify;

[0049] (5) Extrusion molding: inject the curd into the mold, and the pressure is 0.8MPa and pressed for 25min to form;

[0050] (6) Pack the shaped hemp tofu and pasteurize it at 65-85° C. for 20-30 min...

Embodiment 2

[0051] The preparation of embodiment 2 hemp tofu

[0052] (1) Pre-swelling: select the mildew-free shelled hemp seeds, wash them and soften them with steam, and the steam pressure used is 4MPa;

[0053] (2) Refining: Defining the fully swollen hemp seeds and water at a ratio of 1:5 (without removing slag) to obtain hemp milk;

[0054] (3) Thermal coagulation: Hemp milk is slowly heated to 80°C in a boiling water bath for 10 minutes, then cooled to 50°C in a water bath;

[0055] (4) TG enzyme cross-linking: adding 3‰ of the total amount of hemp protein to activate TG enzyme (16000u / g) at 50°C in advance, and keeping it at 50°C for 90 minutes to solidify;

[0056] (5) Extrusion molding: inject the curd into the mold, and the pressure is 0.8MPa and pressed for 15min to form;

[0057] (6) Pack the shaped hemp tofu and pasteurize it at 65-85° C. for 20-30 minutes.

Embodiment 3

[0058] The preparation of embodiment 3 hemp tofu

[0059] (1) Pre-swelling: select the mildew-free shelled hemp seeds and wash them to soften with steam. The steam pressure used is 3MPa;

[0060] (2) Refining: Refining the fully swollen hemp seeds and water at a ratio of 1:5, passing through 100 meshes to obtain hemp milk; drying the filtered filter residue and then superfine grinding to obtain hemp dietary fiber ;

[0061] (3) Thermal coagulation: Hemp milk is slowly heated to 77°C in a boiling water bath for 15 minutes, and then cooled to 45°C in a water bath;

[0062] (4) TG enzyme cross-linking: adding 4‰ of the total amount of hemp protein to activate TG enzyme (16000u / g) at 50°C in advance, and keeping it at 50°C for 60 minutes to solidify;

[0063] (5) Extrusion molding: inject the curd into the mold, and the pressure is 0.8MPa and pressed for 250min to form;

[0064] (6) Pack the shaped hemp tofu and pasteurize it at 65-85° C. for 20-30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com