Non-magnetic planet shaft and machining process thereof

A processing technology and technology of planetary shaft, applied in the field of non-magnetic planetary shaft and its processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

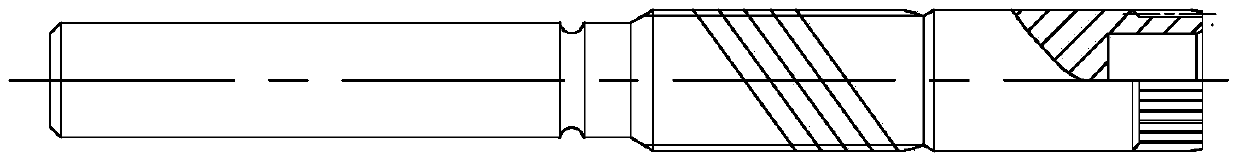

[0024] The shape of the non-magnetic planet shaft in the embodiment is as figure 1 As shown, it is made of austenitic stainless steel 0Cr18Ni9 material. In order to meet the technical requirements, the processing process adopted by the non-magnetic planetary shaft is: blanking→solution treatment→surface oxalate treatment→extruding splines and thickening→machining→rolling oblique splines→straightening→grinding Processing→nitrocarburizing→degreasing and cleaning.

[0025] Specifically, the processing technology of the non-magnetic planet shaft includes the following steps:

[0026] (1), blanking: the blank is a smooth cylindrical body, and the material is austenitic stainless steel 0Cr18Ni9, which is non-magnetic and has high plasticity and toughness;

[0027] (2) Solution treatment: heat the blank to 1000~1200℃, keep it warm for 15~20 minutes, and then quick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com