A lithium-sulfur battery sandwich, a preparation method thereof, and a lithium-sulfur battery

A lithium-sulfur battery and interlayer technology, which is applied in the manufacture of battery electrodes, lithium batteries, and electrolyte batteries, can solve problems such as the deterioration of lithium-sulfur battery cycle stability, and achieve the effects of improving electrochemical performance, inhibiting the shuttle effect, and preventing migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a preparation method of the lithium-sulfur battery interlayer, comprising the following steps:

[0028] Mixing the shearing agent and the organic solvent to obtain a mixed solution;

[0029] The mixed solution is infiltrated into the carbon nanotube conductive paper to obtain a lithium-sulfur battery interlayer.

[0030] In the present invention, the shear agent is mixed with an organic solvent to obtain a mixed liquid; in the present invention, the organic solvent is preferably one or more of N-methylpyrrolidone (NMP) and ethanol.

[0031] After obtaining the mixed solution, the present invention infiltrates the mixed solution into the carbon nanotube conductive paper to obtain an interlayer; in the present invention, the volume ratio of the quality of the shearing agent to the organic solvent is preferably (1g: 200ml), More preferably (1 g: 150 ml), most preferably (1 g: 100 ml).

[0032] In the present invention, the carbon nanot...

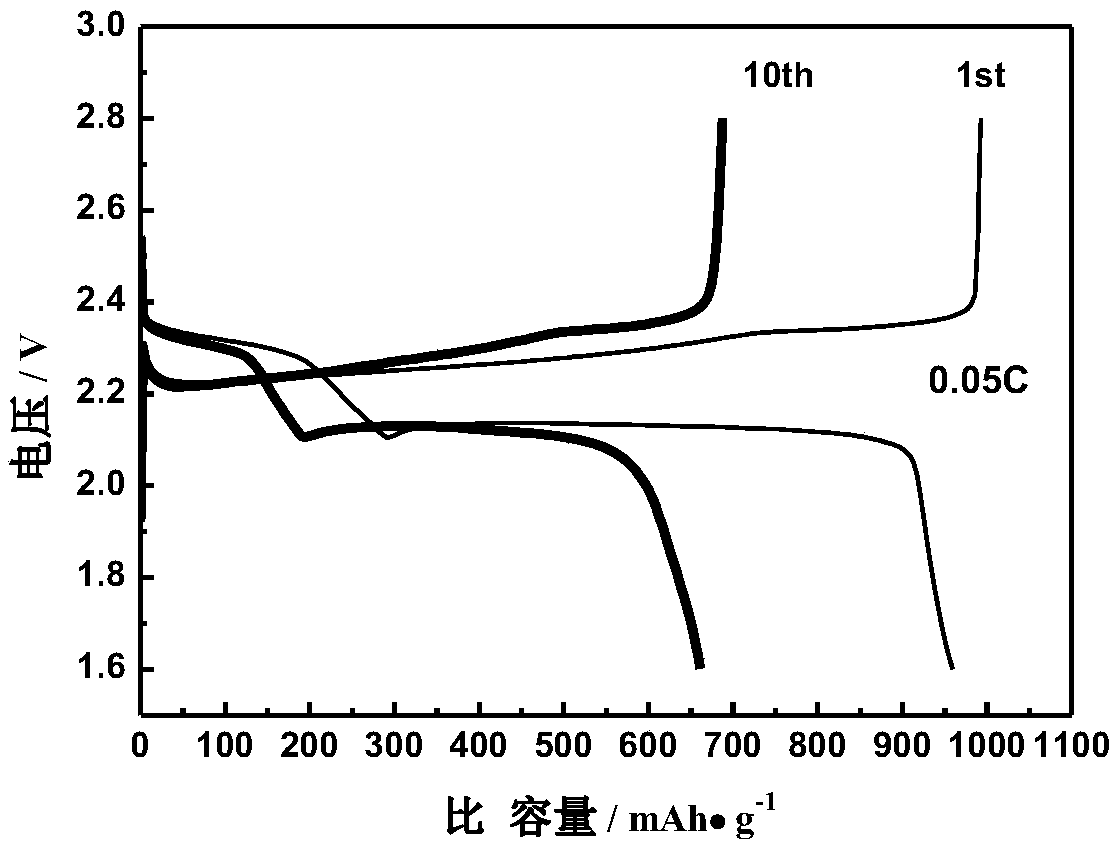

Embodiment 1

[0071] Preparation of carbon nanotube conductive paper:

[0072] Disperse 0.5 g of ball-milled carbon nanotubes and 0.05 g of sodium lauryl sulfate in 200 mL of deionized water, sonicate for 30 minutes, and stir with a high-speed shear for 30 minutes to obtain a carbon nanotube dispersion;

[0073] Mix 0.5g of paper fiber with 500mL of deionized water, and use a high-speed shear to break the paper fiber into a paper fiber suspension;

[0074] The carbon nanotube dispersion and the paper fiber suspension were mixed, sheared for 30 minutes, and filtered under a negative pressure of 0.06Mpa to obtain carbon nanotube paper.

[0075] Preparation of interlayer:

[0076] Dissolve 0.5g of dithiothreitol in 20mL of NMP, uniformly infiltrate into the carbon nanotube paper; dry at 60°C for 12 hours, slice with a microtome to obtain the mezzanine.

[0077] Preparation of positive electrode sheet:

[0078] The active material sulfur, carbon nanotubes, conductive carbon black and polyv...

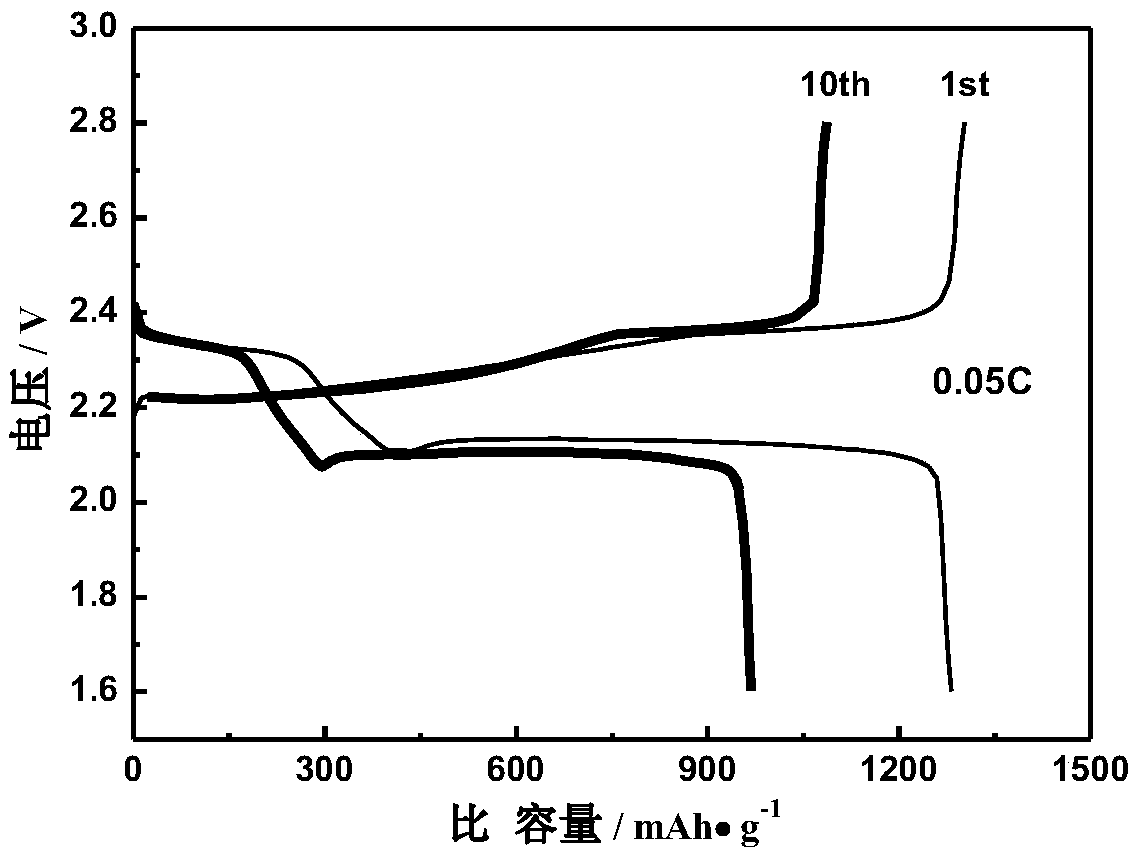

Embodiment 2

[0083] Preparation of carbon nanotube conductive paper:

[0084] Disperse 0.5 g of ball-milled carbon nanotubes and 0.05 g of sodium lauryl sulfate in 200 mL of deionized water, sonicate for 30 minutes, and stir with a high-speed shear for 30 minutes to obtain a carbon nanotube dispersion;

[0085] Mix 0.5g of paper fiber with 200mL of deionized water, and use a high-speed shear to break the paper fiber into a paper fiber suspension;

[0086] Mix the carbon nanotube dispersion with the paper fiber suspension, shear for 30 minutes, and filter under a negative pressure of 0.06Mpa to obtain carbon nanotube paper;

[0087] Preparation of interlayer:

[0088] Dissolve 1.5g of dithiothreitol in 20mL of NMP, and evenly soak into the carbon nanotube paper. Dry at 60°C for 12 hours, slice with a microtome the mezzanine.

[0089] Preparation of positive electrode sheet:

[0090] The active material sulfur, carbon nanotubes, conductive carbon black and polyvinylidene fluoride were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com