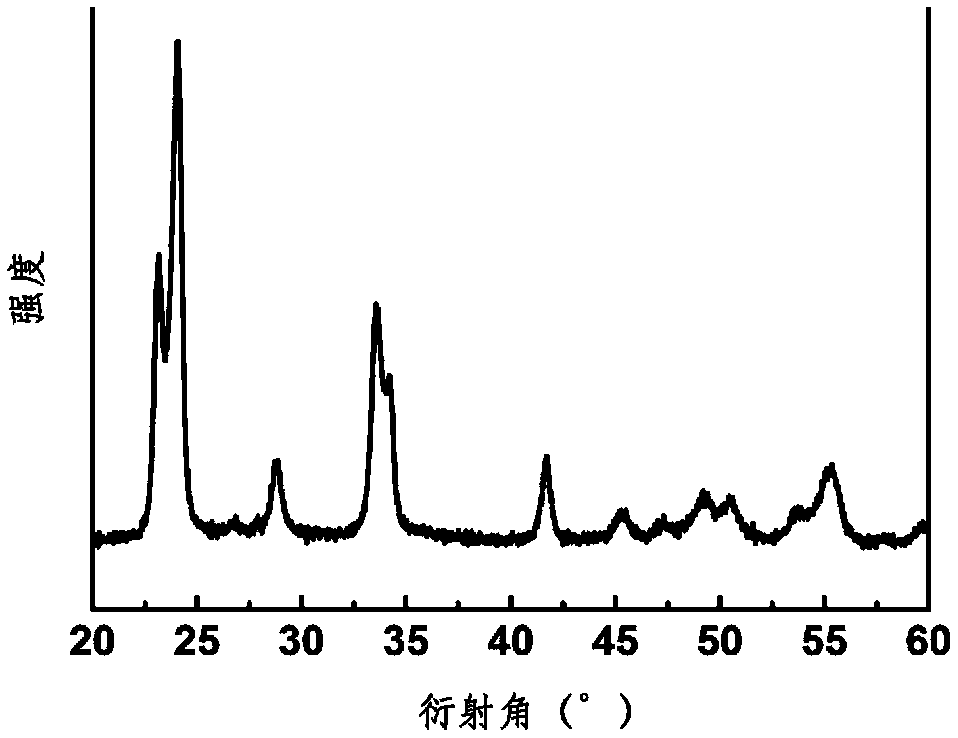

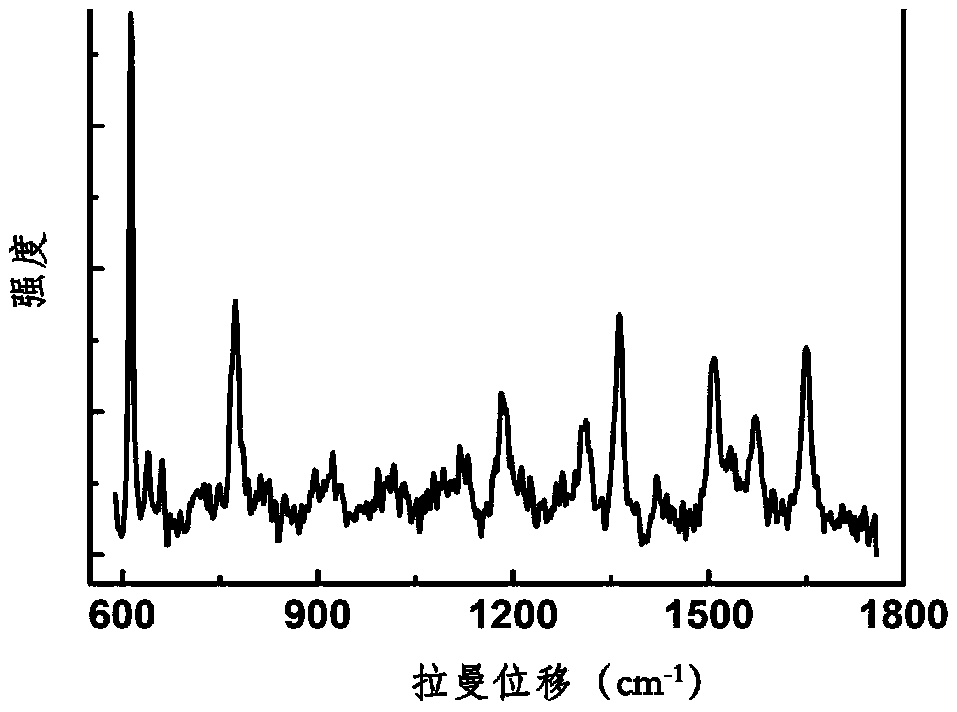

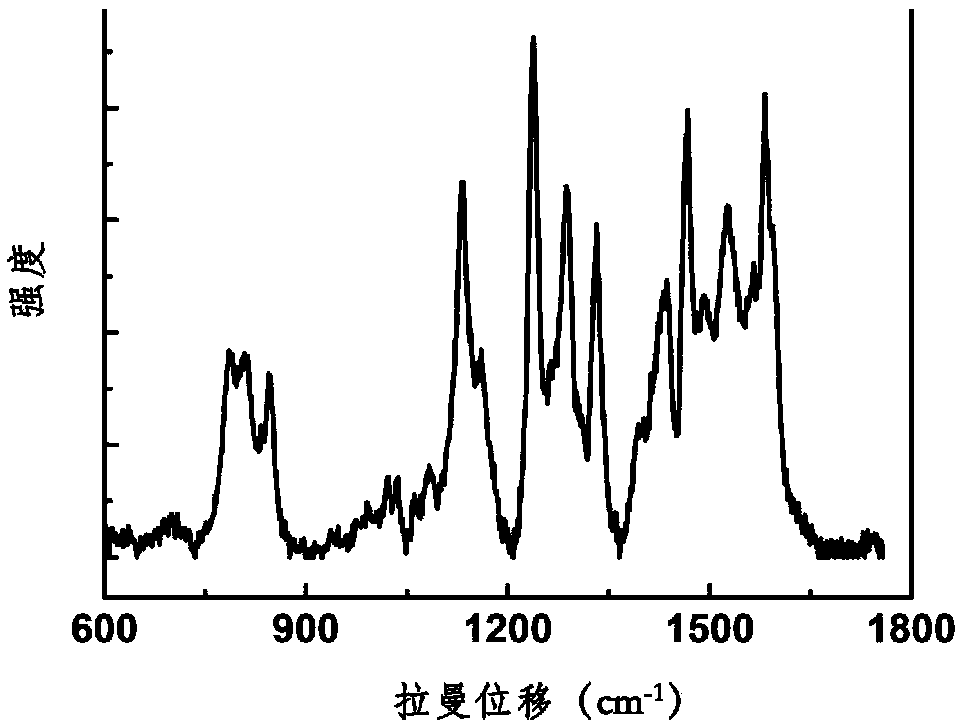

Preparation method of tungsten oxide film

A technology of tungsten oxide and tungsten trioxide, applied in measuring devices, instruments, material analysis by optical means, etc., can solve the problems of uneconomical and effective method of high-temperature hydrogen reduction, cumbersome process, expensive equipment, etc., and achieve safe equipment. , the process is simple, the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The concrete steps of preparation are:

[0032] Step 1, first anneal the ammonium tungstate powder at 300°C for 4 hours; wherein, the particle size of the ammonium tungstate powder is 0.1 μm to obtain tungsten trioxide powder. Then mix the two according to the weight ratio of tungsten trioxide powder and water at a ratio of 0.2:100 to obtain an aqueous solution of tungsten trioxide.

[0033] In step 2, sodium borohydride is first added to the aqueous tungsten trioxide solution, so that the concentration of sodium borohydride in the aqueous tungsten trioxide solution is kept at 0.5 mol / L, and reacted for 5 hours to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the speed is 4000r / min, and the time is 10min, and the washing process is to use distilled water and ethanol to separate the solid matter Carry out 2 alternate washings,...

Embodiment 2

[0036] The concrete steps of preparation are:

[0037] Step 1, first anneal the ammonium tungstate powder at 350°C for 3 hours; wherein, the particle size of the ammonium tungstate powder is 0.5 μm to obtain tungsten trioxide powder. Then mix the two according to the weight ratio of tungsten trioxide powder and water at a ratio of 1:75 to obtain an aqueous solution of tungsten trioxide.

[0038] Step 2, firstly add sodium borohydride to the tungsten trioxide aqueous solution, keep the concentration of sodium borohydride in the tungsten trioxide aqueous solution at 1 mol / L, and react for 3.5 hours to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotation speed is 4500r / min, and the time is 8.75min, and the washing process is to use distilled water and ethanol to separate the solid The solid matter was alternately washed twice, th...

Embodiment 3

[0041] The concrete steps of preparation are:

[0042] Step 1, first anneal the ammonium tungstate powder at 400°C for 3 hours; wherein, the particle size of the ammonium tungstate powder is 1 μm to obtain tungsten trioxide powder. Then mix the two according to the weight ratio of tungsten trioxide powder and water at a ratio of 17:50 to obtain an aqueous solution of tungsten trioxide.

[0043] In step 2, sodium borohydride is first added to the aqueous tungsten trioxide solution, so that the concentration of sodium borohydride in the aqueous tungsten trioxide solution is maintained at 2.5 mol / L, and reacted for 2.5 hours to obtain a reaction solution. Then the reaction solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotating speed is 5000r / min, and the time is 7.5min, and the washing process is to use distilled water and ethanol to separate the solid The solids were washed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com