A kind of biodegradable Zn-Mo system zinc alloy and preparation method thereof

A biodegradable, zinc alloy technology, applied in the field of medical implant materials, can solve the problems of not being suitable for the use of medical implant materials, achieve the effect of improving mechanical properties and biological functionality, promoting repair and healthy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

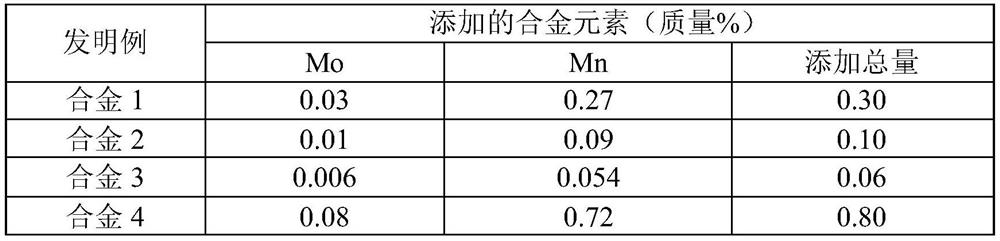

[0054]The composition, preparation and performance test of biodegradable Zn-Mo-Mn ternary zinc alloy.

[0055]The chemical compositions of the four invention examples of the zinc alloy are as shown in Table 1-1, the total amount of added alloying elements does not exceed 0.8%, and the balance is Zn, which is a low-alloy zinc alloy with low cost. The preparation process of the zinc alloy is: smelting Mn-10Mo master alloy→smelting Zn-Mo-Mn ternary zinc alloy→hot rolling→heat treatment→cold rolling. The smelting of the Mn-10Mo master alloy uses high-purity Mo and Mn powder as raw materials, batches according to the mass percentage, Mn content 90% and Mo content 10%, mixed and placed in a vacuum induction furnace, vacuumed and heated The temperature is raised to 1500° C., the temperature is kept for 15 minutes, and the Mn-10Mo master alloy is obtained by pouring into a casting mold. The smelting of the Zn-Mo-Mn ternary zinc alloy uses the Mn-10Mo master alloy and high-purity Zn block as ra...

Embodiment 2

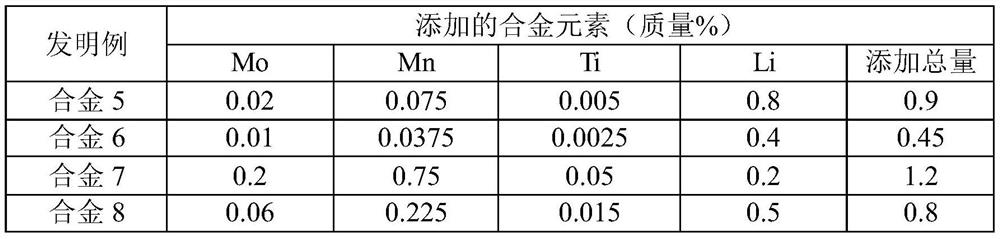

[0066]The composition, preparation and performance test of the biodegradable Zn-Mo-Mn-Ti-Li five-element alloy.

[0067]The chemical composition of the four invention examples of the zinc alloy is as shown in Table 2-1, the total amount of added alloying elements does not exceed 1.2%, and the balance is Zn, which is a low-alloy zinc alloy with low cost. The preparation process of the zinc alloy is: smelting Mn-20Mo-5Ti master alloy → smelting Zn-Mo-Mn-Ti-Li five-element zinc alloy → hot extrusion → heat treatment → hot extrusion. The smelting of the Mn-20Mo-5Ti master alloy uses high-purity Mn, Mo and Ti powders as raw materials, batches according to the mass percentage of 75% Mn, 20% Mo and 5% Ti, and puts them in a vacuum induction furnace after mixing. After vacuuming, the temperature is raised to 1600° C., the temperature is kept for 10 minutes, and then poured into a mold to obtain the Mn-20Mo-5Ti master alloy. The smelting of the Zn-Mo-Mn-Ti-Li five-element zinc alloy uses the Mn...

Embodiment 3

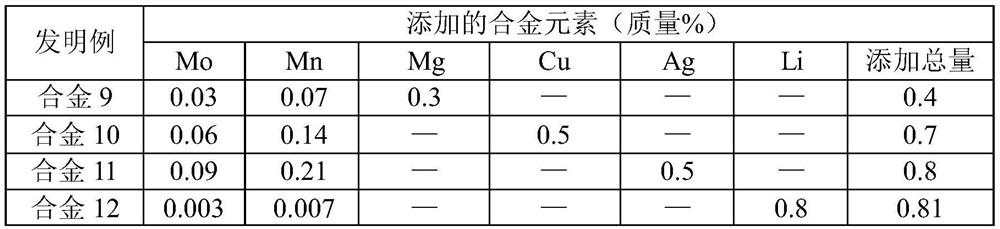

[0076]Composition, preparation and performance test of biodegradable Zn-Mo quaternary zinc alloy.

[0077]The zinc alloy contains 4 kinds of alloying elements, of which 3 kinds are necessary alloying elements: Zn, Mo and Mn, and the fourth kind is a further added alloying element. The chemical composition of the four embodiments of the zinc alloy is as shown in Table 3-1, the total amount of added alloying elements does not exceed 0.81%, and the balance is Zn, which is a low-alloy zinc alloy with low cost. The preparation process of the zinc alloy is: smelting Mn-30Mo master alloy→smelting Zn-Mo quaternary zinc alloy→hot extrusion→heat treatment→cold rolling. The smelting of the Mn-30Mo master alloy uses high-purity Mo and Mn powder as raw materials, and mixes them in a mass percentage of 70% Mn and 30% Mo. After mixing, they are placed in a vacuum induction furnace, and the temperature is raised to 1700°C after being vacuumed. 10 minutes, then pouring into a casting mold to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com