A device and method for continuous production of ferrovanadium nitride alloy

A ferrovanadium nitride and nitriding technology, applied in the field of metallurgy, can solve the problems of energy loss in the preparation process, large area occupation, complex process flow, etc., to achieve full utilization, reduce production costs, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

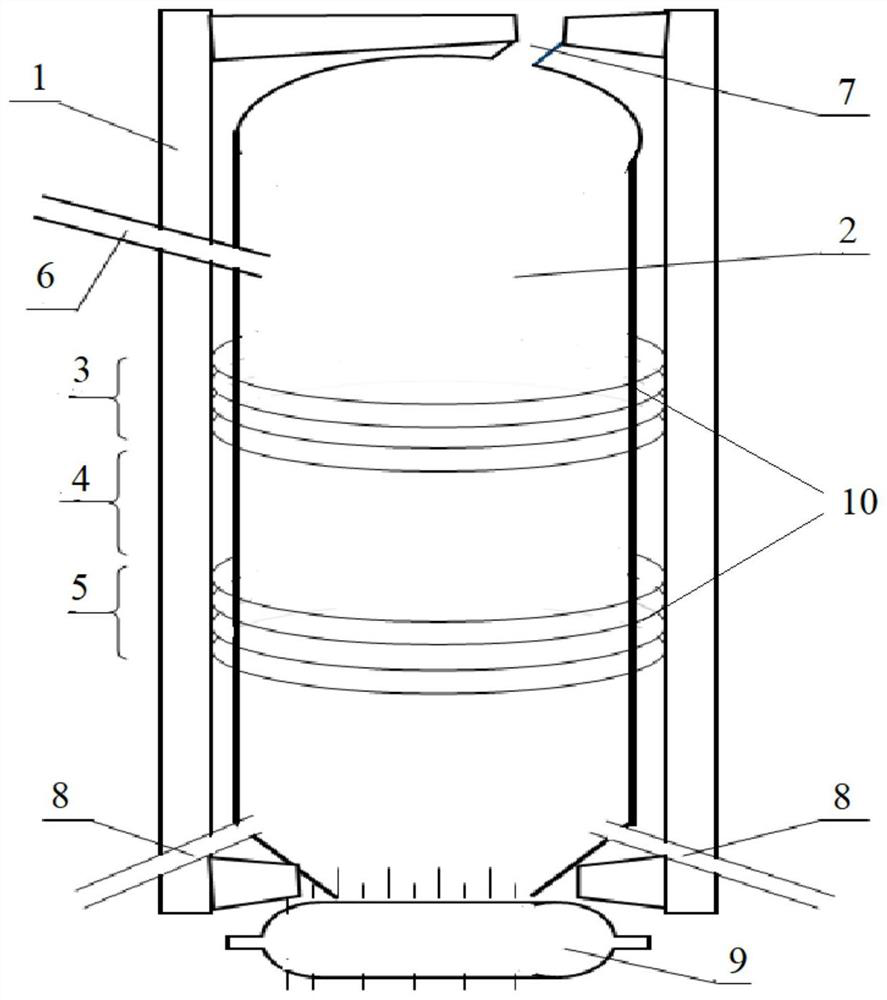

[0050] This embodiment provides a device for continuous production of vanadium-iron alloy, such as figure 1 As shown, the device includes a furnace body, the furnace body includes a shell 1 and a furnace 2, the furnace body is provided with a heating reaction zone, and the heating reaction zone includes a preheating reduction zone 3 from top to bottom, and the heat radiation Zone 4 and nitriding reaction zone 5, the position of the preheating reduction zone 3 and the nitriding reaction zone 5 in the furnace body is provided with a heating coil 10 for heating the material; the bottom of the heating reaction zone is provided with a cooling zone, so The bottom of the cooling zone is provided with a discharge machine 9, the discharge machine is a rotary discharge machine with intermittent teeth distributed above, the top of the furnace body is provided with an air outlet 7, and the side wall is provided with a feeding port 6 and an air inlet 8 , the feeding port 6 is higher than t...

Embodiment 2

[0052] This embodiment provides a method for continuously producing vanadium nitride ferroalloy, which is carried out by using the device provided in embodiment 1.

[0053] The target composition of the ferrovanadium nitride alloy prepared by the invention is: 64.5-66.3wt% of vanadium; 13.1-14.2wt% of nitrogen; the balance is iron and other unavoidable impurities.

[0054] Prepare as follows:

[0055] (1) Put V 2 o 3 , graphite and iron powder were ground to -80 mesh respectively, and then mixed according to the mass ratio of 100:30:33. At the same time, an appropriate amount of corn flour and water were added for mixing. For 3.5cm block materials, dry at 100-105℃ for 15 hours before use;

[0056] (2) Add the massive material obtained in step (1) through the feeding port 6 and enter the preheating reduction zone 3 in the furnace body. The heating coil 10 in the preheating reduction zone 3 is energized and heated to 500° C. for the reduction reaction for 5 hours. The gas in...

Embodiment 3

[0062] This embodiment provides a method for continuously producing vanadium nitride ferroalloy, which is carried out by using the device provided in embodiment 1.

[0063] The target composition of the ferrovanadium nitride alloy prepared by the invention is: 64.5-66.3wt% of vanadium; 13.1-14.2wt% of nitrogen; the balance is iron and other unavoidable impurities.

[0064] Prepare as follows:

[0065] (1) Put V 2 o 5 , coke and iron powder are ground to -80 mesh respectively, and then the ingredients are mixed according to the mass ratio of 100:38:28. At the same time, some powdered grains and water are added for mixing. After the mixing is completed, the pressure is controlled at 7MPa and pressed to a thickness. For bulk materials less than 3.5cm, dry at 100-105°C for 20 hours before use;

[0066] (2) Add the bulk material obtained in step (1) through the feeding port 6, and enter the preheating reduction zone 3 in the furnace body. The heating coil 10 in the preheating re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com