Preparation method of chrome tanning solution

A technology for chrome tanning liquor and waste liquor, which is applied in the field of chrome tanning liquor preparation, can solve the problems of high difficulty in sludge treatment, difficulty in sedimentation, increased sludge yield from chrome mordant dyeing waste liquor and the like, and achieves good acid and alkali resistance and stability. , reduce environmental pollution and achieve the effect of resource treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

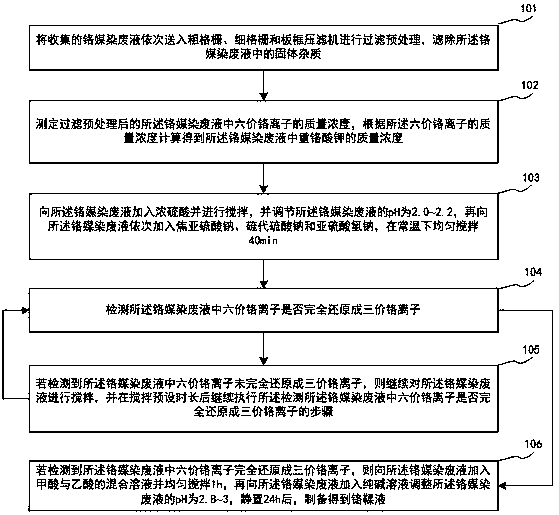

[0026] figure 1 It is a preparation method of a chrome tanning solution shown according to an exemplary embodiment, such as figure 1 As shown, the method includes:

[0027] In step 101, the collected chrome mordant waste liquid is sequentially sent to a coarse screen, a fine screen, and a plate-and-frame filter press for pre-filtering to filter out solid impurities in the chrome-mordant waste liquid.

[0028] Wherein, the solid impurities can be meat slag, dander and the like.

[0029] Step 102, measuring the mass concentration of hexavalent chromium ions in the chromium mordant waste liquid after filtration pretreatment, and calculating the mass concentration of potassium dichromate in the chromium mordant waste liquid according to the mass concentration of the hexavalent chromium ions .

[0030] Wherein, the method for measuring the mass concentration of hexavalent chromium ions in the chromium mordant waste liquid after filtration pretreatment may be to adopt ferrous amm...

Embodiment 2

[0047] (1) The collected chromium mordant waste liquid is sequentially sent to a coarse grid, a fine grid and a plate and frame filter press for filtration pretreatment to filter out solid impurities in the chrome mordant waste liquid.

[0048] (2) Determination of the mass concentration of hexavalent chromium ions in the chromium mordant waste liquid after filtration pretreatment is 0.18g / L, and calculate the heavy chromium in the chromium mordant waste liquid according to the mass concentration of the hexavalent chromium ions The mass concentration of potassium acid potassium is 1.08g / L.

[0049] (3) Add concentrated sulfuric acid to the chrome mordant waste liquid and stir, and adjust the pH of the chrome mordant waste liquid to 2.1, then add sodium pyrosulfite, sodium thiosulfate and sulfurous acid to the chrome mordant waste liquid in sequence Sodium hydrogen, stirred evenly at normal temperature for 40min, after finishing the reaction, the pH of the chromium mordant wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com