Device and technology for manufacturing bio-based fuel through catalytic cracking of self-heating oil

A bio-based fuel oil, catalytic cracking technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of easy catalyst deactivation, low conversion rate, excessive energy consumption, etc., to reduce catalyst deactivation and save costs. , the effect of improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

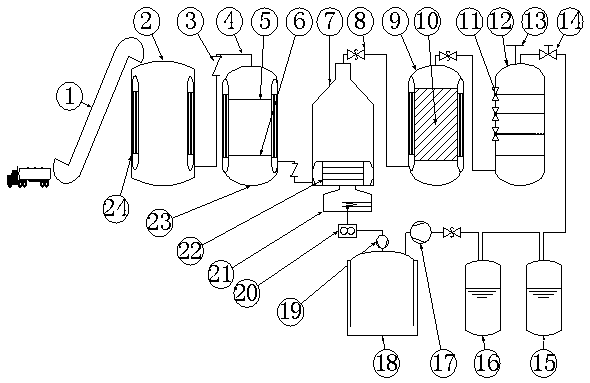

[0024] Embodiment 1: as figure 1 As shown, a device for producing bio-based fuel oil by self-heating oil catalytic cracking includes a raw material pretreatment mechanism, an oil gasification mechanism, an oil catalytic cracking mechanism, a crude product rectification and purification mechanism, and a gas product recovery mechanism. The pretreatment mechanism, the oil gasification mechanism, the oil catalytic cracking mechanism and the crude product rectification and purification mechanism are connected in sequence, and the oil gasification mechanism and the crude product rectification and purification mechanism are connected through the gas product recovery mechanism;

[0025] Described raw material pretreatment mechanism comprises elevator 1, material storage chamber 2 and impurity removal tower 23, elevator 1 is connected in the material storage chamber 2, and the lower end of material storage chamber 2 is connected into the upper end of impurity removal tower 23 by pipelin...

Embodiment 2

[0031] Embodiment 2: Wherein elevator 1 and storage room 2 are welded, check valve 3, safety valve 8, shut-off valve I11, shut-off valve II13, shut-off valve 14 and the insulation pipeline 4 are threaded, the gasification tower 7, the rectification tower 12, the scrubber 15, the drying chamber 16, the gas storage chamber 18 and the insulation pipeline 4 are threaded, the gas compressor 17, the gas The pressure reducer 19, the gas flow controller 20 and the insulation pipeline 4 are threadedly connected, and the primary screen 5, the secondary screen 6 and the impurity removal tower 23 are movable to ensure timely replacement of the screens, catalytic A movable connection is adopted between the cracking reaction bed 10 and the reaction tower 9, a movable connection is adopted between the gas heater 21, the electric heating device 22 and the gasification tower 7, and the heating device 24 is connected with the storage room 2, the reaction tower 9, and the impurity removal tower ...

Embodiment 3

[0033] Embodiment 3: utilize above-mentioned device to produce the technique of jatropha oil as follows:

[0034] 1) Raw material pretreatment: Pure jatropha oil does not need to be filtered, so it is only necessary to heat and keep the raw material in winter and cold environments. The temperature in the storage chamber is greater than 20°C to ensure good fluidity of raw materials.

[0035] 2) Grease gasification: When starting the equipment for the first time, an electric heating system is used. When the whole system is running continuously, the combustible gas generated by the reaction can be used to heat the equipment, and the pressure in the gasification tower is 0.23±0.1MPa.

[0036] 3) Oil catalytic cracking: The catalyst is HZSM-5 with a silicon-aluminum ratio of 25, a temperature of 550±50°C, and a mass space velocity of gaseous raw materials of 1.5±0.5h-1.

[0037] 4) Distillation and purification of crude products: Fractional distillation of liquid products at 100°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com