Device and method for removing nitrogen and carbon from sewage with high ammonia-nitrogen content and low carbon-nitrogen ratio

A technology with low carbon-to-nitrogen ratio and high ammonia-nitrogen, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem that nitrate nitrogen cannot meet the discharge standard, and achieve biochemical stability , avoid competition, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

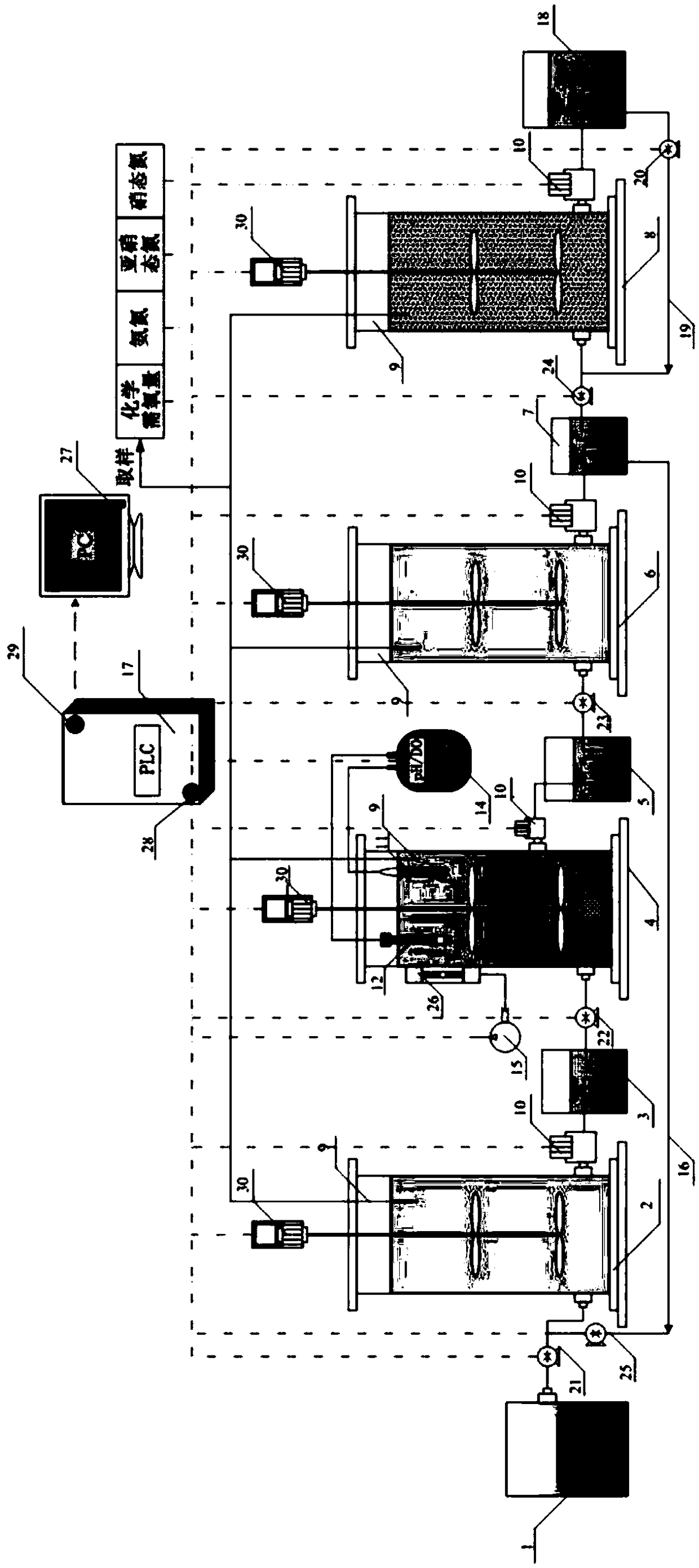

[0104] The denitrification and carbon removal device for high ammonia nitrogen and low carbon nitrogen ratio sewage is as follows: figure 1 shown, including

[0105] Raw water tank 1, denitrification carbon removal S reactor 2, intermediate water tank after carbon removal 3, partial short-range nitrification reactor 4, intermediate water tank after nitrification 5, anaerobic ammonium oxidation reactor 6, intermediate water tank after ammonia oxidation, which are connected in sequence through pipelines Water tank 7, ion exchange resin reactor 8 and water outlet tank 18;

[0106] The denitrification carbon removal SBR reactor 2, the partial short-path nitrification SBR reactor 4, the anammox SBR reactor 6 and the ion exchange resin SBR reactor 8 all use SBR reactors;

[0107] The interior of the denitrification carbon removal reactor 2, part of the short-range nitrification reactor 4, the anammox reactor 6 and the ion exchange resin reactor 8 are all equipped with a stirrer 30 ...

Embodiment 2

[0128] The form of the anammox reactor in Example 1 is changed from the SBR reactor to the UASB reactor, and the UASB reactor is mainly composed of a drainage area, a main reaction area, a three-phase separation area, a precipitation area, a gas collection device and a reflux device, etc. It is composed of parts, with a height of 1.2m, an inner diameter of 12cm, and an effective volume of the reaction zone of 12L. The outside of the reactor is wrapped with black sponge to protect the anammox bacteria inside from the light. The UASB reactor is removed because it does not require stirring figure 1 The agitator inside the anaerobic ammonium oxidation reactor is shown, and the agitator control interface in the corresponding PLC controller is removed at the same time. All other devices are compatible with figure 1 same.

[0129] The COD concentration of a certain aquaculture wastewater is 5220mg / L, the total nitrogen concentration is 4951mg / L, and the ammonia nitrogen concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com