Oil-soluble formaldehyde scavenger

A formaldehyde scavenger and oil-soluble technology, which is applied in the field of oil-soluble formaldehyde scavenger, can solve the problems of ineffective removal of formaldehyde, unfavorable popularization and promotion, and noise generation, and achieve good formaldehyde capture performance, good catalytic activity, and good permeability. Effect

Inactive Publication Date: 2018-12-28

襄阳云创环保有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing formaldehyde scavengers are generally sprayed on the surface of artificial boards to form a film, and formaldehyde is purified by physical adsorption technology, negative ion high-voltage electrostatic dust removal technology or room temperature catalytic oxidation method, etc. Physical adsorption technology can only absorb and store harmful substances, but cannot eventually eliminate them. And there are situations such as adsorption saturation and desorption, so the adsorption material must be replaced frequently; negative ion high-voltage electrostatic technology is a physical process that can effectively remove smoke and dust in the air, but it has no obvious effect on the removal of formaldehyde. Secondly, it is expensive and needs to be used. Electricity will generate noise, which is not conducive to large-scale popularization; room temperature catalytic oxidation method has high efficiency in removing formaldehyde, but it will produce secondary pollutants, such as methanol, formic acid, formaldehyde polymer and other toxic substances, and some substances will also adhere to the board First, it affects the quality of the board, and it is usually a reversible reaction. When the formaldehyde concentration is lower than a certain limit, the formaldehyde purification efficiency is significantly affected; secondly, the reaction area of the membrane is limited. Once the membrane fails, the free formaldehyde in the artificial board will still Will be released in large quantities, causing indoor air pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

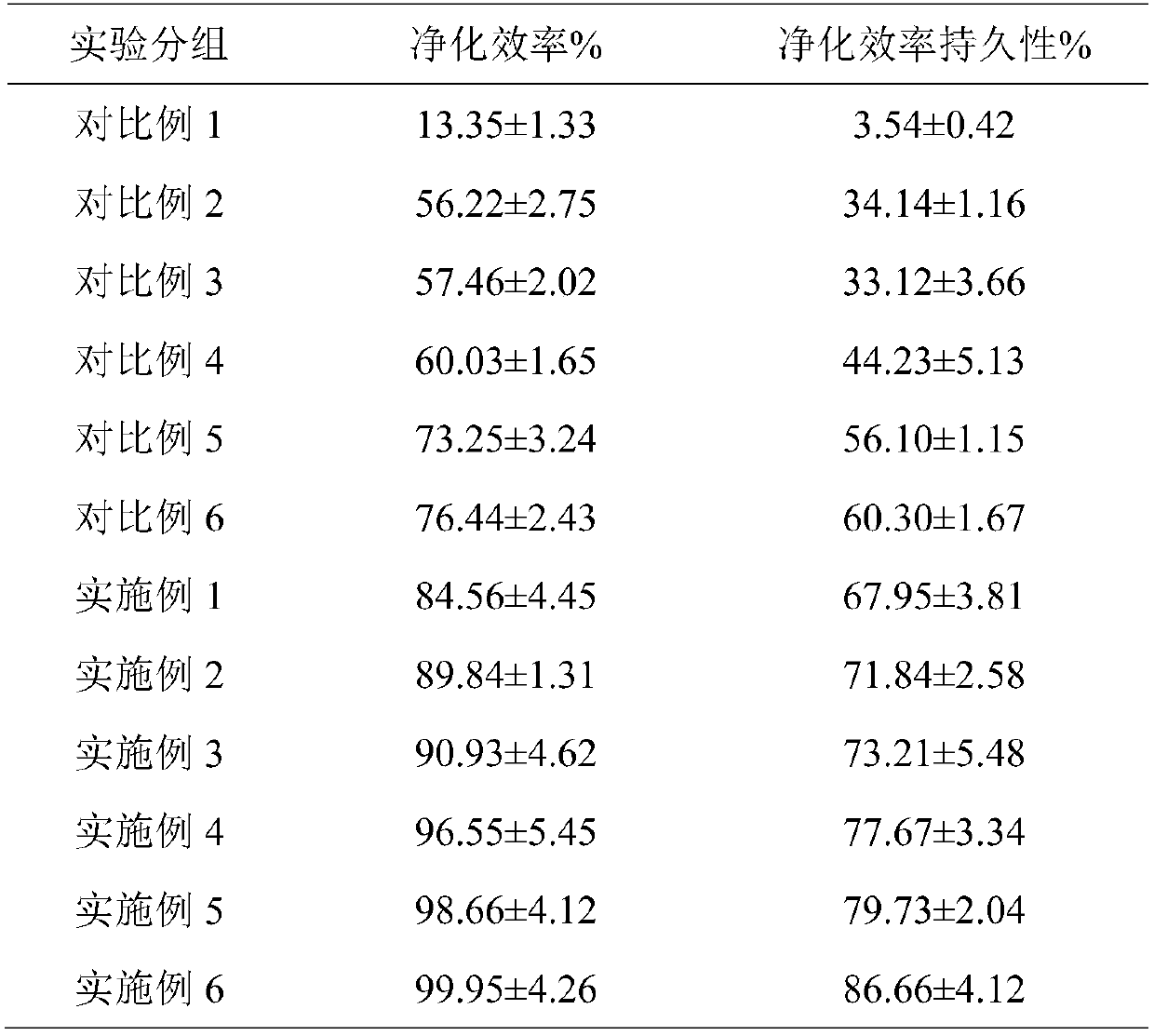

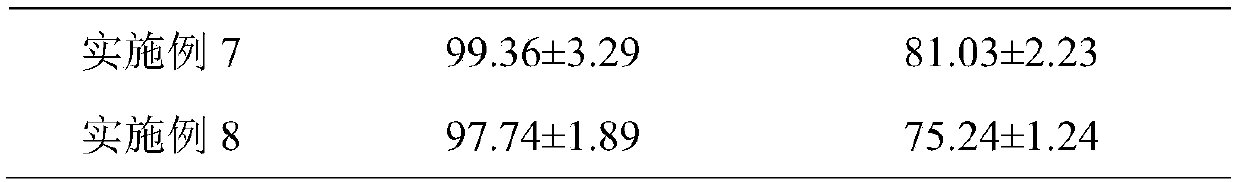

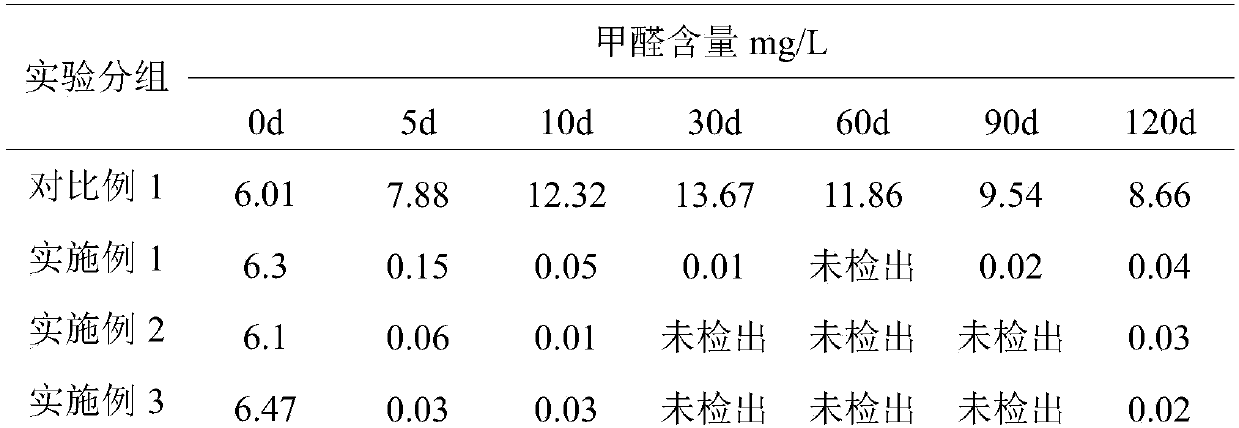

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an oil-soluble formaldehyde scavenger and belongs to the technical field of indoor air scavengers. The scavenger specifically comprises a spherical carrier and a dicyandiamidepowder reactant adhering to the spherical carrier, wherein the spherical carrier is subjected to surface modification with N-octadecyl biquaternary ammonium salt. The spherical carrier formed throughmodification with N-octadecyl biquaternary ammonium salt adopts a hydrophobic structure on the surface and can penetrate through an artificial board to adhere to the surface of the board; gaseous formaldehyde around the board can be gathered to the periphery of the spherical carrier under the trapping action of N-octadecyl biquaternary ammonium salt, so that the formaldehyde can make contact and react with dicyandiamide, after water molecules of a product are absorbed, dicyandiamide resin gradually settles on the surface of the spherical carrier and adsorbed by the spherical carrier, and the scavenger has high formaldehyde scavenging efficiency and lasting effects under the synergistic effect of the three factors.

Description

technical field The invention relates to the technical field of indoor air purifiers, in particular to an oil-soluble formaldehyde scavenger. Background technique Artificial board is a board made by adding chemical adhesives to the scraps produced during the processing of wood. There are many types of wood-based panels, commonly used decorative wood-based panels such as particle boards, medium-density boards, blockboards, plywood, and fireproof boards. Because they have their own different characteristics, they are used in different furniture manufacturing fields. Because urea-formaldehyde resin and phenolic resin have the characteristics of low price, corrosion resistance and durability, urea-formaldehyde resin and phenolic resin are used as adhesives to produce artificial boards that have been widely used in interior decoration building materials. However, urea-formaldehyde resin and phenolic resin are used as adhesives. The manufactured artificial panels always contain ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/72B01D53/81B01D53/86B01D53/02

CPCB01D53/72B01D53/02B01D53/81B01D53/8668B01D2253/20B01D2257/704B01D2258/06

Inventor 姚贺飞

Owner 襄阳云创环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com