Pulping method using high-concentration brine as cooking medium

A concentrated brine and medium technology, applied in the field of pulp and paper making, can solve the problems of difficult recycling and treatment of high-salt wastewater and large water resource consumption, and achieve the effect of reducing the content of impurities and various ions and avoiding consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

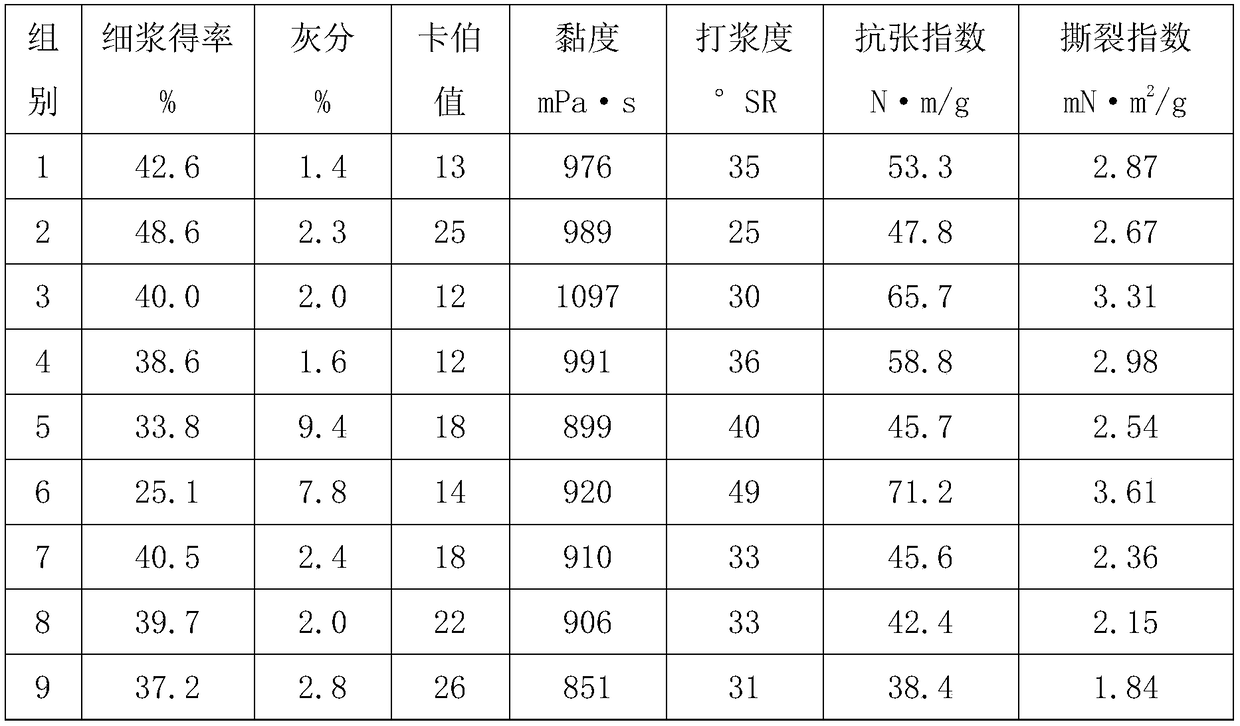

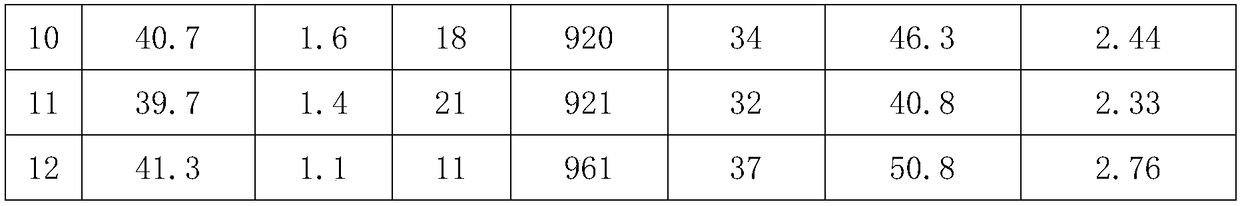

Examples

Embodiment 1

[0062] The pulping method using high-concentration brine as the cooking medium of the present embodiment comprises the following steps:

[0063] (1) Add a precipitant and a flocculant to the high-concentration brine, mix well, and then settle it until the turbidity of the supernatant is lower than 25FTU and the color is lower than 15 degrees, remove the precipitate, and obtain the pretreated high-concentration brine;

[0064] Wherein, the high-concentration brine is seawater, and its main components are as follows: the salt content of seawater is 35.5g / kg, wherein, the content of sodium element is 10.77g / kg, the content of magnesium element is 1.29g / kg, calcium The element content is 0.412g / kg. The flocculant is PAC, and its dosage is that the volume ratio of the flocculant to the high-concentration brine is 5:1000. The precipitation agent is NaOH and Na 2 CO 3 It is mixed according to the mass ratio of 4:1, and the dosage is 5.5:1000 of the mass ratio of the precipitant t...

Embodiment 2

[0071] The pulping method using high-concentration brine as the cooking medium of the present embodiment comprises the following steps:

[0072] (1) Add a precipitant and a flocculant to the high-concentration brine, mix well, and then settle it until the turbidity of the supernatant is lower than 25FTU and the color is lower than 15 degrees, remove the precipitate, and obtain the pretreated high-concentration brine;

[0073] Wherein, the high-concentration brine is brackish water, and its main components are as follows: the salt content of brackish water is 10.6g / kg, wherein, the content of sodium element is 3.26g / kg, and the content of magnesium element is 0.20g / kg, the content of calcium element is 0.54 / kg. The flocculant is PAM, and its dosage is that the volume ratio of the flocculant to the high concentrated brine is 20:1000. The precipitation agent is NaOH and Na 2 CO 3 It is mixed according to the mass ratio of 1:2, and its dosage is 2:1000 of the mass ratio of th...

Embodiment 3

[0080] The pulping method using high-concentration brine as the cooking medium of the present embodiment comprises the following steps:

[0081] (1) Add a precipitant and a flocculant to the high-concentration brine, mix well, and then settle it until the turbidity of the supernatant is lower than 25FTU and the color is lower than 15 degrees, remove the precipitate, and obtain the pretreated high-concentration brine;

[0082] Wherein, the high-concentration brine is high-salt wastewater produced by RO treatment, and its main components are as follows: the salt content of high-concentration brine is 45.7g / kg, wherein the content of sodium element is 13.90g / kg, and the content of magnesium element The content is 1.66g / kg, and the content of calcium element is 0.531g / kg. The flocculant is formed by mixing PAC and PAM in a mass ratio of 1:2, and the dosage is that the volume ratio of the flocculant to the high-concentration brine is 12:1000. The precipitation agent is NaOH and N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com