Process for producing crisp bread

A technology for bread and craftsmanship, applied in the direction of processing dough, dough fermenter, baking method, etc., can solve problems such as low production efficiency, inconsistent product quality, and premature proofing of dough, so as to improve production efficiency, save manpower, ensure The effect of product quality standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

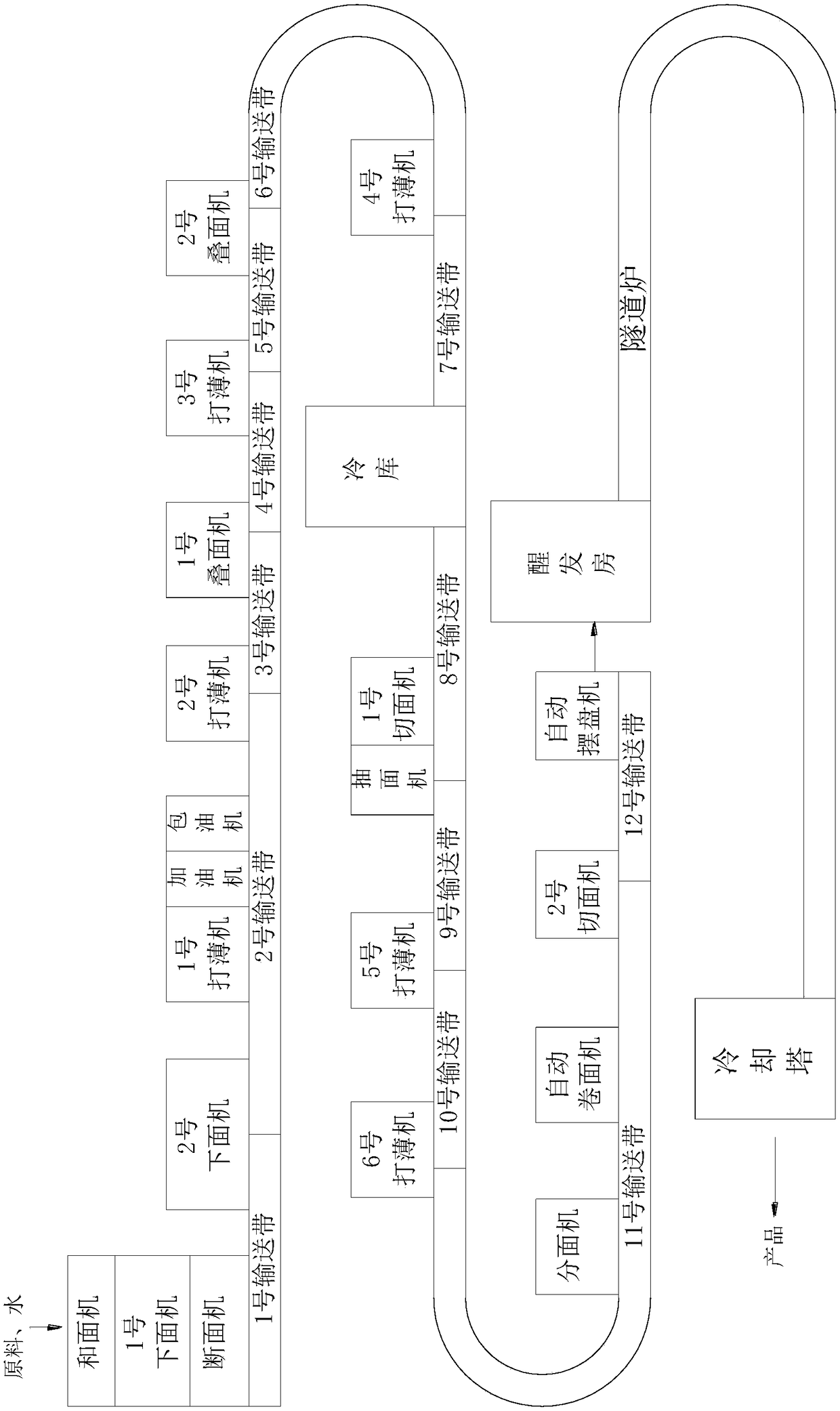

[0037] Such as figure 1 Shown, a kind of technique of producing crisp bread, comprises the steps:

[0038] S1. Kneading dough: first control the room temperature at 20-26°C, and control the humidity at 68%-75%, then add the prepared raw materials and water into the kneading machine for stirring. Wherein, the raw materials include the following components in parts by weight: 900 parts of wheat flour, 8 parts of yeast, 150 parts of sugar, 100 parts of eggs, 8 parts of salt, 1 part of improver, and the parts by weight of the water are 350 parts.

[0039] Wherein, the water is mixed with normal temperature water and ice at a weight ratio of 1:4, and a small amount of calcium carbonate and magnesium carbonate are added, and the pH value of the water is 5-6; the wheat flour is selected from strong gluten wheat flour; The improving agent includes soybean powder, emulsifier, vitamin C, moisture retaining agent and compound enzyme; the emulsifier is selected from monoglyceride emulsif...

Embodiment 2

[0052] A process for producing crispy bread, the process steps are the same as in Example 1, the difference is that the raw materials for kneading dough include the following components in parts by weight: 1000 parts of wheat flour, 11 parts of yeast, 180 parts of sugar, 120 parts of eggs, and 9 parts of salt part, 3.5 parts of improving agent, and the parts by weight of described water are 500 parts; The compound enzyme in improving agent is the composition of amylase, protease, fat inhibiting enzyme, lipoxygenase.

Embodiment 3

[0054] A process for producing crispy bread, the process steps are the same as in Example 1, the difference is that the raw materials for kneading dough include the following components in parts by weight: 1100 parts of wheat flour, 15 parts of yeast, 250 parts of sugar, 200 parts of eggs, and 13 parts of salt 4 parts, 4 parts of improving agent; The parts by weight of described water is 550 parts; The compound enzyme in improving agent is the composition of amylase and fat-inhibiting enzyme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com