Reflective water-based heat-insulating coating and preparation method thereof

A thermal insulation coating, reflective technology, applied in reflective/signal coatings, anti-corrosion coatings, coatings, etc., can solve the problems of uneven coating surface, poor thermal insulation performance, low surface reflectivity, etc., to achieve fast response speed , Optimize the coating modification conditions, the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

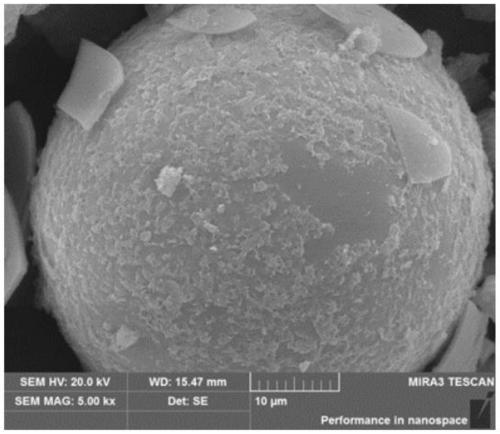

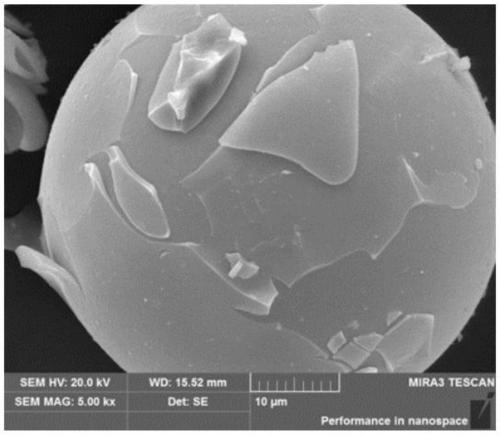

[0076] The volume ratio of tetrabutyl titanate, absolute ethanol, distilled water and glacial acetic acid is 1:2.5:0.2:0.15. Completely mix two parts of absolute ethanol with 2 / 3 of the total volume with tetrabutyl titanate and glacial acetic acid, and stir in a constant temperature water bath at 30°C at 300r / min for 40min to obtain a tetrabutyl titanate solution. The other 1 / 3 of absolute ethanol is fully mixed with water and a pH regulator to obtain a mixed aqueous solution, and the obtained mixed aqueous solution is evenly added dropwise to the tetrabutyl titanate solution at a speed of 1ml / min, and a uniform light yellow transparent sol is obtained after the drop is completed , control the pH value of the system at 3.5, continue to stir for 40 minutes, and then place it in the refrigerator for later use.

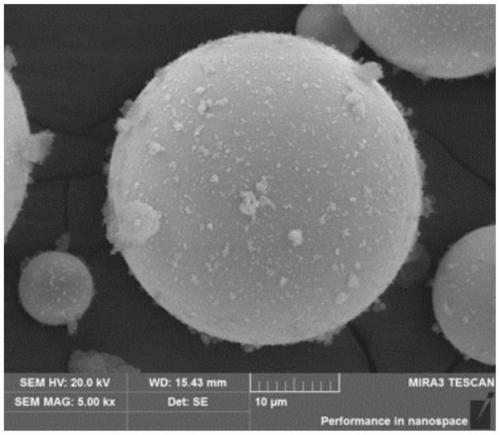

[0077] Take 3g of hollow glass microspheres, immerse in 100ml of organic solvent washing solution with a volume ratio of ethanol and distilled water of 10:1, ultrasonica...

Embodiment 2

[0084] A reflective water-based heat-insulating coating, including the following raw materials in weight percentage: 40% of silicon acrylic emulsion, 15% of unmodified common hollow glass microspheres, dispersant (Nopco SN-5040 and sodium hexametaphosphate) 0.8 %, defoamer (Nopco NXZ) 0.4%, thickener (hydroxyethyl cellulose) 0.55%, film-forming aid (alcohol ester-12) 1.8%, antifreeze agent (ethylene glycol) 0.6%, pH adjuster (ammonia water) 0.16%, preservative (Hemings DeuAdd-MB) 0.2%, balance water.

[0085] The preparation method of the reflective water-based heat-insulating coating of the present embodiment comprises the following steps: I. take a certain amount of water, dispersant, and defoamer, place it under the disperser and stir for 8min at a speed of 300r / min; II. add Thickener, stir at 1500r / min for 20min; III. Then reduce the speed to 300r / min, add emulsion, film-forming aid, antifreeze, preservative in turn, stir for 15min to make it evenly mixed; IV. At a rotati...

Embodiment 3

[0088] A reflective water-based heat-insulating paint, comprising the raw materials in the following percentages by weight: 40% of silicon acrylic emulsion, 15% of functional filler (hollow glass microsphere / anatase titanium dioxide thin film composite material (prepared in embodiment 1)), Dispersant (Nopco SN-5040 and sodium hexametaphosphate) 0.8%, defoamer (Nopco NXZ) 0.4%, thickener (hydroxyethyl cellulose) 0.55%, film-forming aid (alcohol ester -12) 1.8%, antifreeze (ethylene glycol) 0.6%, pH adjuster (ammonia) 0.16%, preservative (Hemings DeuAdd-MB) 0.2%, and the balance is water.

[0089] The preparation method of the reflective water-based heat-insulating coating of the present embodiment comprises the following steps: I. take a certain amount of water, dispersant, and defoamer, place it under the disperser and stir for 8min at a speed of 300r / min; II. add Thickener, stir at 1500r / min for 20min; III. Then reduce the speed to 300r / min, add emulsion, film-forming aid, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com