Precursor solution and high temperature atomized flame synthesis of yttrium aluminum composite oxide nanopowder and its preparation method

A composite oxide and nano-powder technology, which is applied in the field of high-temperature atomization flame synthesis of yttrium-aluminum composite oxide nano-powder and its preparation, can solve the problem that it is difficult to obtain nano-sized spherical particles of uniform size, the powder particle has a wide particle size distribution, The problem of uneven powder particles, etc., achieves the effect of simple raw materials and equipment, fast synthesis speed, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

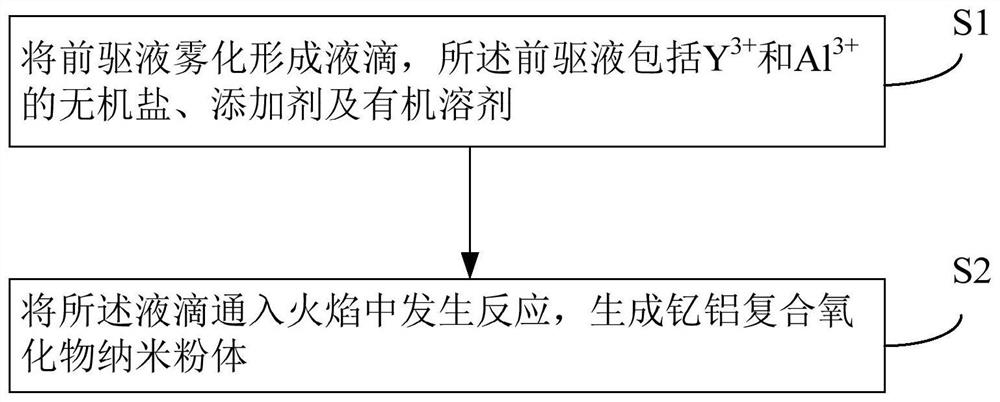

[0040] see figure 1 , the embodiment of the present invention provides a high-temperature atomization flame synthesis of yttrium-aluminum composite oxide nanopowder preparation method, comprising:

[0041] S1, atomize the precursor liquid to form droplets, the precursor liquid includes Y 3+ and Al 3+ inorganic salts, additives and organic solvents; and

[0042] S2, passing the droplet into a flame to react to generate yttrium-aluminum composite oxide nanopowder.

[0043] The additive is used with the Y 3+ and Al 3+ The inorganic salt is generated in the droplet formed by the precursor solution under the action of the flame, and the volatilization temperature is lower than the Y 3+ and Al 3+ substances of inorganic salts, thereby increasing the Y 3+ and Al 3+ The volatility of the inorganic salts in the flame.

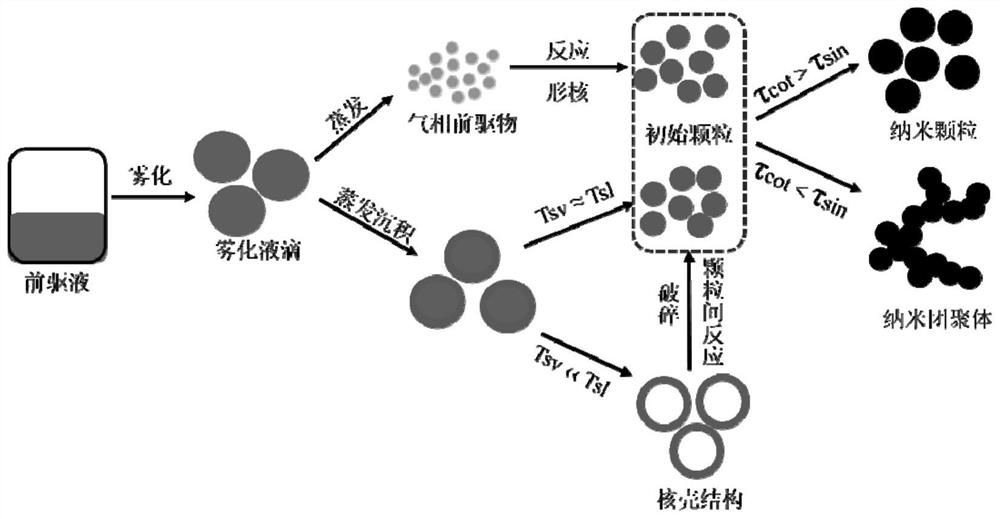

[0044] see figure 2 , Different types of precursors determine the synthesis and growth paths of subsequent nanoparticles. The synthesis and growth of nanopar...

Embodiment 1

[0056] Yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O) and aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) is a precursor, dissolved in pure ethanol, the additive is 2-ethylhexanoic acid, and the mass fraction in the precursor solution is 50%. Prepare the solution according to the stoichiometric ratio, Y in the precursor solution 3+ :Al 3+ =3:5, Y in the precursor solution 3+ and Al 3+ The total concentration is 0.4mol / L. After the precursor liquid is atomized, it enters the burner flame to obtain YAG spherical nanoparticle powder.

Embodiment 2

[0058] Example 2 is the same as Example 1, except that the mass fraction of the additive 2-ethylhexanoic acid in the precursor solution is 18%.

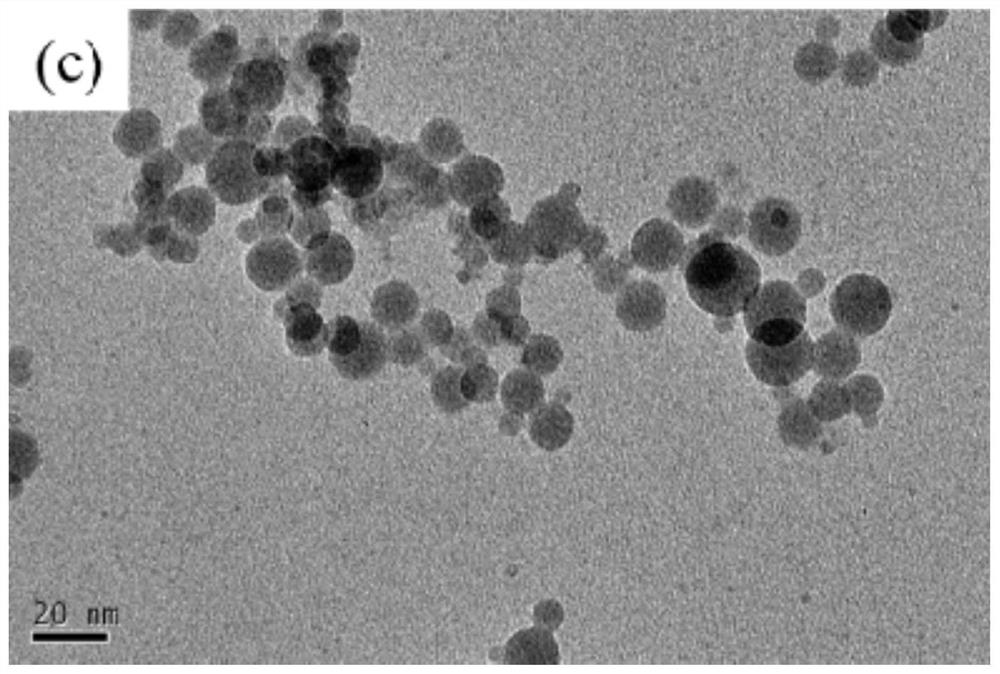

[0059] see image 3 and Figure 4, it can be seen that due to the synthesis path of the atomized precursor liquid in the flame is controlled in the "gas phase-particles", the particles in the nanopowders obtained in Examples 1 and 2 have good sphericity and narrow particle size distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com