Casting defect eliminating method

A technology for casting defects and defects, applied in the field of casting defect elimination, can solve problems such as cracking, and achieve the effect of improving welding repair quality, saving time and ensuring overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

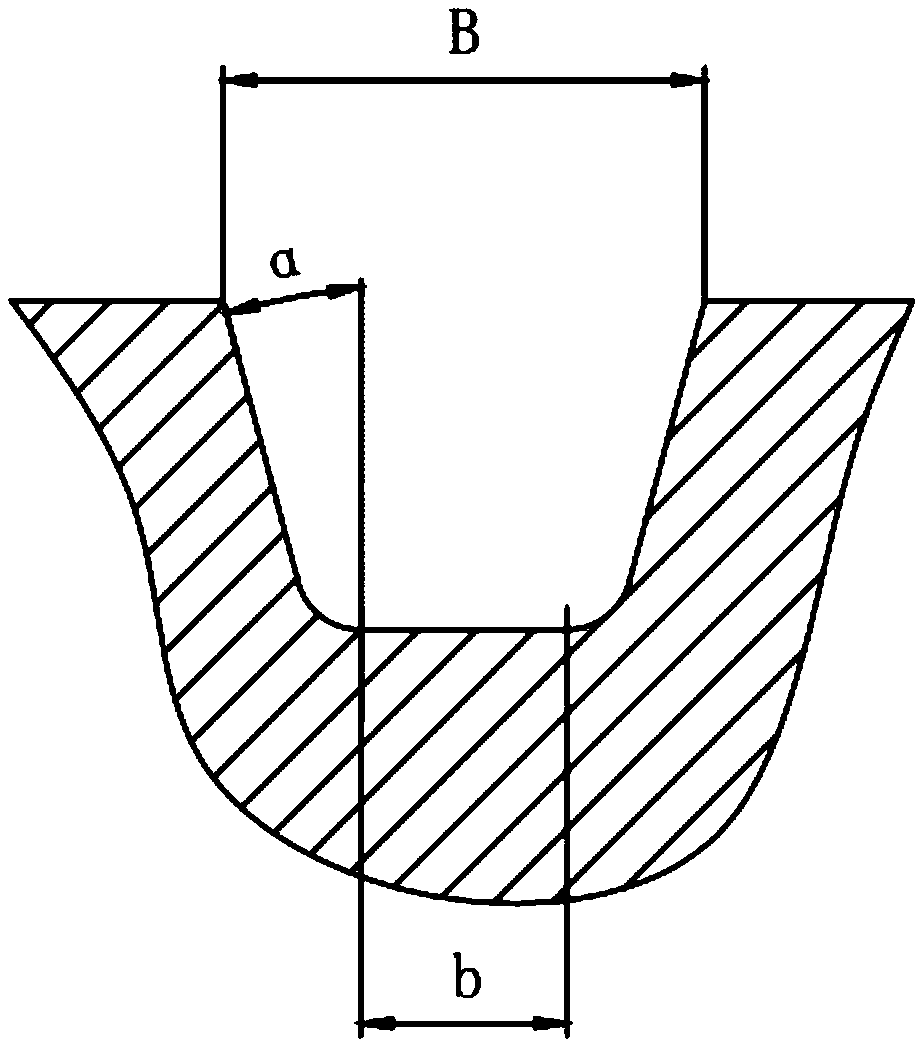

[0039] For the defects of large steel castings, it is difficult to repair them by conventional repair methods, and cracks are prone to appear in the repaired area. To solve this problem, the characteristics of steel castings and the mechanism of cracks are analyzed. Generally speaking, its structure is a thick and large cross-section structure. During production, the liquid metal solidifies for a long time after pouring, so the final obtained crystal structure is relatively coarse and segregated seriously, which is easy to cause fluctuations in carbon equivalent, so that the casting itself has a large Crack tendency, and due to the large size of the casting, it is easy to produce a hardened structure in the near-seam area of the base metal during welding repair, and the proportion of the base metal melting into the first layer of weld metal is as high as 30%, resulting in the inclusion of weld metal. The high carbon content eventually leads to hot and cold cracks in the weld ...

Embodiment 2

[0053] The casting defect elimination method of this embodiment is further improved on the basis of Embodiment 1, and the local preheating in the third step is carried out with an oxyacetylene flame. The local preheating temperature is ≥100°C, and the preheating area is ≤100mm from the groove edge; the overall preheating temperature is ≥250°C. The cost of preheating with oxyacetylene flame is low, and the preheating equipment is simple and convenient to move, and the heating area and heating temperature are convenient to control; when using oxyacetylene flame for local preheating, the heat control within the preheating range is from small to large, And make the heat evenly distributed in the heated area to avoid excessive local temperature. The overall preheating is carried out by conventional methods. The preheating temperature should not be lower than the range described in this embodiment, otherwise the due effect of pre-welding preheating cannot be achieved.

Embodiment 3

[0055] The method for eliminating casting defects in this embodiment is further improved on the basis of Embodiment 2, and the fourth step adopts a metal carbon dioxide gas shielded welding method. The purity of carbon dioxide gas is ≥99.7%, and the water content of the gas is less than 0.005%. The welding wire is According to the characteristics of large steel castings, in order to strengthen the ability of resisting cold cracks and hot cracks after welding repair, and at the same time ensure that it matches the strength of the base metal, after many experiments and studies, the selected Welding wire is the most suitable, and the mechanical properties of the deposited metal of the welding wire are as follows:

[0056] Tensile strength (σ b )MPa

Yield strength (σ 0.2 ) MPa

Elongation (δ 5 )

≥500

≥420

≥22

[0057] During welding repair, the wind speed at the welding repair site should be less than 2m / s; the process parameters used when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com